Pipe Bender Guides⁚ A Comprehensive Guide

Pipe bender guides are essential tools for achieving precise and consistent bends in pipes and tubes. They act as a template, guiding the pipe through the bending process and ensuring accurate angles. This guide delves into the world of pipe bender guides, exploring their various types, importance, and practical applications. From choosing the right guide to troubleshooting common issues, this resource provides everything you need to master the art of pipe bending.

Introduction

Pipe bending is a fundamental skill in various industries, from plumbing and HVAC to automotive and manufacturing. Achieving precise and consistent bends is crucial for creating functional and aesthetically pleasing structures. Pipe bender guides are essential tools that facilitate this process, ensuring accuracy and minimizing the risk of damage to the pipe. These guides act as templates, directing the pipe through the bending process and ensuring the desired angle is achieved. Their use is particularly important when working with delicate materials like copper or stainless steel, where precise bending is critical to prevent kinks or fractures.

This comprehensive guide will explore the world of pipe bender guides, covering their different types, their importance in achieving accurate bends, and the factors to consider when choosing the right guide for a specific application. We will also delve into practical aspects, including step-by-step instructions for using pipe bender guides, common applications, and troubleshooting tips for resolving common bending issues. By the end of this guide, you will have a thorough understanding of pipe bender guides and be equipped to confidently utilize them in your projects.

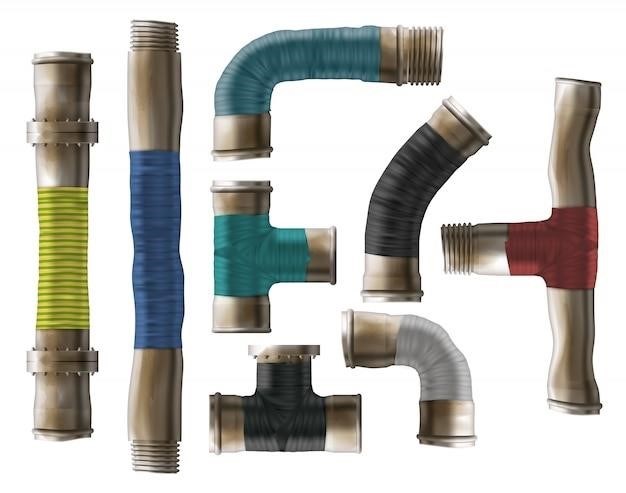

Types of Pipe Bender Guides

Pipe bender guides come in a variety of designs, each suited for specific pipe sizes and bending applications. Understanding the different types available is crucial for selecting the right guide for your project. Here’s a breakdown of common types⁚

- Standard Formers⁚ These are the most basic type of guide, designed for creating straight bends at specific angles, typically 90 degrees or 45 degrees. They are typically made from durable materials like aluminum or steel and are compatible with a wide range of pipe sizes.

- Multi-Radius Formers⁚ These guides offer more flexibility, allowing you to create bends with varying radii. They often feature multiple slots or grooves, accommodating different bend angles and pipe diameters. This versatility makes them ideal for intricate projects requiring complex bends.

- Offset Formers⁚ These specialized guides are designed for creating offset bends, where the bend is not directly in line with the original pipe direction. Offset formers are essential for applications like plumbing, where pipes need to navigate around obstacles.

- Internal Bending Springs⁚ These springs are inserted inside the pipe during bending, preventing kinks and ensuring a smoother bend. They are particularly useful for bending thin-walled pipes or delicate materials.

The choice of guide depends on the specific pipe size, material, and desired bend angle. Consider the project requirements and the available guide options to ensure you select the most suitable tool for the job.

Importance of Pipe Bender Guides

Pipe bender guides play a crucial role in achieving precise and professional-looking bends in pipework. Their importance extends beyond aesthetics, impacting the functionality, safety, and longevity of any pipe system. Here are key reasons why pipe bender guides are indispensable⁚

- Accurate Bends⁚ Guides ensure consistent and accurate bend angles, eliminating guesswork and reducing the risk of errors. This precision is crucial for ensuring proper pipe alignment and flow, preventing leaks and ensuring a smooth and efficient system.

- Preventing Kinks and Crushing⁚ Guides help distribute bending force evenly, preventing kinks, creases, and crushing of the pipe material. This is particularly important for thin-walled pipes or delicate materials that are prone to damage during bending.

- Improved Durability⁚ By minimizing stress points and ensuring consistent bends, guides contribute to the overall durability of the pipe system. This reduces the risk of leaks and failures over time, enhancing the longevity of the installation.

- Enhanced Safety⁚ Accurate bends and a properly supported pipe during bending reduce the risk of accidents and injuries. This is particularly important when working with large or heavy pipes, where improper bending techniques can lead to dangerous situations.

- Professional Finish⁚ Guides contribute to a neat and professional finish, enhancing the overall appearance of pipework. This is crucial for projects where aesthetics are important, such as in residential or commercial settings.

In summary, pipe bender guides are essential tools for ensuring precise, safe, and durable pipe bending. They are an investment that pays off in the long run by minimizing errors, maximizing efficiency, and enhancing the overall quality of your pipework.

Factors to Consider When Choosing a Pipe Bender Guide

Selecting the right pipe bender guide is crucial for achieving accurate bends and ensuring the longevity of your pipework. Here are some key factors to consider when making your choice⁚

- Pipe Material and Size⁚ Different guides are designed for specific pipe materials, such as copper, steel, or aluminum. Additionally, each guide is typically rated for a specific pipe diameter range. Ensure the guide you choose is compatible with the material and size of the pipe you’ll be bending.

- Bend Radius⁚ The bend radius refers to the curvature of the bend. Guides come in various bend radii, and the appropriate radius depends on the application. Consider the desired bend angle and the required clearance for the pipe after bending.

- Bend Angle⁚ Some guides are specifically designed for 90-degree bends, while others offer flexibility for different angles. Choose a guide that can accommodate the desired bend angle for your project.

- Guide Material⁚ Guides are made from various materials, such as aluminum or steel. The material choice affects durability and resistance to wear and tear. Consider the frequency of use and the type of pipe you’ll be bending when selecting the material.

- Compatibility with Bender⁚ Ensure the guide you choose is compatible with the type of pipe bender you own. Some benders are compatible with specific guide designs, while others offer a wider range of options.

- Quality and Durability⁚ Invest in high-quality guides from reputable manufacturers. Look for durable construction and features that minimize wear and tear, ensuring long-lasting performance.

By considering these factors, you can select the most appropriate pipe bender guide for your specific needs, ensuring accurate, efficient, and safe pipe bending.

Using Pipe Bender Guides⁚ A Step-by-Step Guide

Using a pipe bender guide is a straightforward process that requires careful attention to detail for achieving precise bends. Here’s a step-by-step guide to help you get started⁚

- Prepare the Pipe⁚ Ensure the pipe is clean and free of any debris or burrs that could interfere with the bending process. If necessary, cut the pipe to the desired length and deburr the edges.

- Select the Guide⁚ Choose a guide that is compatible with the pipe material, size, and bend radius required for your project. Ensure the guide fits securely into the pipe bender.

- Position the Pipe⁚ Insert the pipe into the pipe bender, aligning it with the guide. Ensure the pipe is properly seated and secured in the bender before proceeding.

- Make the Bend⁚ Apply pressure to the bender handle or lever, bending the pipe slowly and steadily. Keep the pipe aligned with the guide throughout the bending process to maintain accuracy.

- Check the Angle⁚ Once the desired bend angle is reached, use a protractor or angle gauge to verify its accuracy. If needed, make minor adjustments to achieve the precise angle.

- Repeat for Multiple Bends⁚ If multiple bends are required, repeat the process, repositioning the pipe in the bender and aligning it with the guide for each bend.

Remember to work carefully and consistently when using a pipe bender guide to ensure accurate and professional-looking results. Always prioritize safety and wear appropriate protective gear while bending pipes.

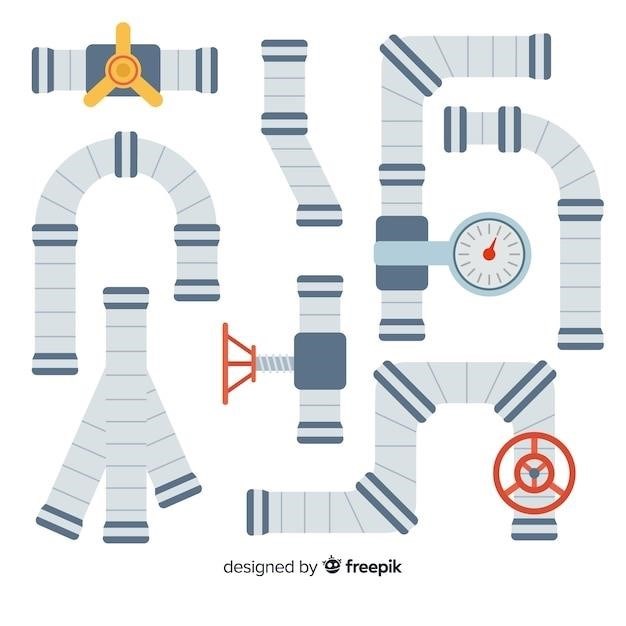

Common Applications of Pipe Bender Guides

Pipe bender guides find widespread use in various industries and applications, playing a crucial role in shaping pipes and tubes for diverse purposes. Here are some common applications where pipe bender guides are indispensable⁚

- Plumbing⁚ Pipe bender guides are essential for plumbers, enabling them to create precise bends in copper, PVC, and other plumbing pipes for installations and repairs. This ensures smooth water flow and leak-free connections.

- HVAC⁚ In heating, ventilation, and air conditioning systems, pipe bender guides are used to shape metal and plastic pipes for refrigerant lines and ductwork, ensuring optimal airflow and efficient operation.

- Automotive⁚ Pipe bender guides are employed in automotive manufacturing and repair to create bends in brake lines, fuel lines, and exhaust pipes, ensuring proper fluid flow and exhaust routing.

- Construction⁚ Pipe bender guides are used in construction for shaping steel and other metal pipes for structural supports, railings, and various other applications. This ensures sturdy and safe structures.

- Manufacturing⁚ In manufacturing, pipe bender guides are used to create precise bends in pipes and tubes for various industrial equipment and machinery, ensuring optimal functionality and performance.

From residential plumbing to large-scale industrial applications, pipe bender guides contribute significantly to the efficient and reliable operation of various systems and structures.

Benefits of Using Pipe Bender Guides

Pipe bender guides offer numerous advantages that enhance the efficiency, accuracy, and overall quality of pipe bending operations. Here are some key benefits of incorporating pipe bender guides into your workflow⁚

- Precise Bends⁚ Pipe bender guides ensure accurate and consistent bends, eliminating guesswork and reducing the risk of errors. This is crucial for achieving proper fit and functionality in various applications.

- Reduced Material Waste⁚ With precise bends, you minimize the need for excess material, reducing waste and saving costs. This promotes sustainable practices and efficient resource utilization.

- Improved Efficiency⁚ Pipe bender guides streamline the bending process, allowing for faster and more efficient operations. This reduces labor time and increases overall productivity;

- Enhanced Durability⁚ By preventing kinks and other deformities during bending, pipe bender guides contribute to the structural integrity and durability of the pipe. This ensures long-lasting performance and reduces the risk of failures.

- Professional Finish⁚ Pipe bender guides create clean and consistent bends, resulting in a professional finish that enhances the overall aesthetics and quality of your work.

The benefits of using pipe bender guides extend beyond simply achieving accurate bends; they contribute to a more efficient, cost-effective, and professional pipe bending process, leading to superior results.

Troubleshooting Common Pipe Bending Issues

While pipe bender guides greatly enhance the bending process, occasional issues can arise. Recognizing and addressing these common problems can ensure smooth and successful bending operations.

- Kinking⁚ If the pipe kinks during bending, it’s often due to insufficient support or excessive force. Ensure the pipe is securely held in the bender and apply gradual pressure. Consider using a bending spring to further protect the pipe.

- Uneven Bends⁚ Uneven bends can occur if the guide is not properly aligned or if the pipe is not consistently positioned. Double-check the guide’s alignment and ensure the pipe is centered and securely clamped before bending.

- Incorrect Angle⁚ Inaccurate angles can result from misinterpreting the bender’s markings or using the wrong guide. Carefully verify the markings and use the appropriate guide for the desired angle.

- Pipe Slipping⁚ Pipe slippage can occur if the clamps are not sufficiently tightened. Ensure the clamps are securely fastened to prevent the pipe from moving during bending.

- Guide Wear⁚ Over time, pipe bender guides can wear down, leading to inaccurate bends. Inspect the guides regularly for wear and replace them as needed to maintain accuracy.

By understanding these common issues and implementing appropriate solutions, you can effectively troubleshoot problems and ensure consistent and accurate pipe bending results.

Safety Precautions When Using Pipe Bender Guides

Pipe bending, while a valuable skill, involves inherent risks if proper safety precautions are not taken. Adhering to these guidelines ensures a safe and productive bending experience⁚

- Eye Protection⁚ Always wear safety glasses or goggles to protect your eyes from flying debris or metal shavings that can occur during bending.

- Gloves⁚ Wear sturdy work gloves to provide protection from sharp edges, cuts, and abrasions.

- Footwear⁚ Wear closed-toe shoes with good grip to maintain balance and stability while bending.

- Clear Work Area⁚ Ensure a clean and clutter-free work area to prevent tripping hazards or obstacles that could interfere with the bending process.

- Proper Lifting Techniques⁚ If handling heavy pipes or benders, use proper lifting techniques to prevent strains or injuries.

- Avoid Overbending⁚ Do not attempt to bend the pipe beyond its recommended bending radius. This can lead to kinking or fracturing of the pipe.

- Regular Inspections⁚ Periodically inspect the pipe bender guide and clamps for signs of wear or damage; Replace any worn or damaged components to ensure safe operation.

- Machine Operation⁚ If using powered pipe benders, familiarize yourself with the manufacturer’s safety instructions and follow them carefully.

By prioritizing safety and adhering to these precautions, you can minimize risks and create a safer environment for pipe bending operations.

Choosing the Right Pipe Bender Guide for Your Needs

Selecting the appropriate pipe bender guide is crucial for achieving accurate and consistent bends. The choice depends on several factors, including the type of pipe, desired bend radius, and the frequency of use. Here’s a breakdown of key considerations⁚

- Pipe Material⁚ Consider the material of the pipe you will be bending, as different materials have varying bending properties. For example, copper pipes require different bending techniques than steel pipes.

- Pipe Diameter⁚ The pipe bender guide should be compatible with the outer diameter of the pipe you intend to bend.

- Bend Radius⁚ Determine the desired bend radius, which is the distance from the center of the bend to the inside of the pipe. This influences the sharpness or gradualness of the bend.

- Bend Angle⁚ Choose a guide that can accommodate the desired bend angle. Some guides are specifically designed for 90-degree bends, while others offer flexibility for various angles.

- Frequency of Use⁚ If you are a professional plumber or a DIY enthusiast who frequently bends pipes, investing in a durable and high-quality guide is recommended. For occasional use, a more affordable option might suffice.

- Compatibility⁚ Ensure the guide is compatible with your existing pipe bender. Some guides are designed for specific bender models.

By carefully considering these factors, you can choose the right pipe bender guide for your specific needs, ensuring accurate and efficient bending results.

Pipe bender guides are indispensable tools for achieving precise and consistent bends in pipework, offering accuracy, efficiency, and safety in various applications. By understanding the different types, benefits, and factors to consider when choosing a guide, you can confidently tackle pipe bending projects.

From basic DIY tasks to professional plumbing installations, pipe bender guides empower you to create clean, leak-free connections. Whether you’re a seasoned plumber or a novice DIY enthusiast, investing in the right guide can make a significant difference in the quality and efficiency of your work. Remember, always prioritize safety by using appropriate tools and techniques, and consult with professionals if you have any doubts or concerns.

With the information presented in this comprehensive guide, you can confidently approach pipe bending projects with precision and confidence, ensuring professional results every time.