Sodium silicate from rice husk ash pdf

20/09/2016 · This video contain Silica Extraction Process from Rice Husk Ash and also it will give you a quick overview that How a rice miller can earn more profit. Rice Husk Ash …

Rice husk large ash content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash, which has wide market and also takes care of ash disposal. Rice husk …

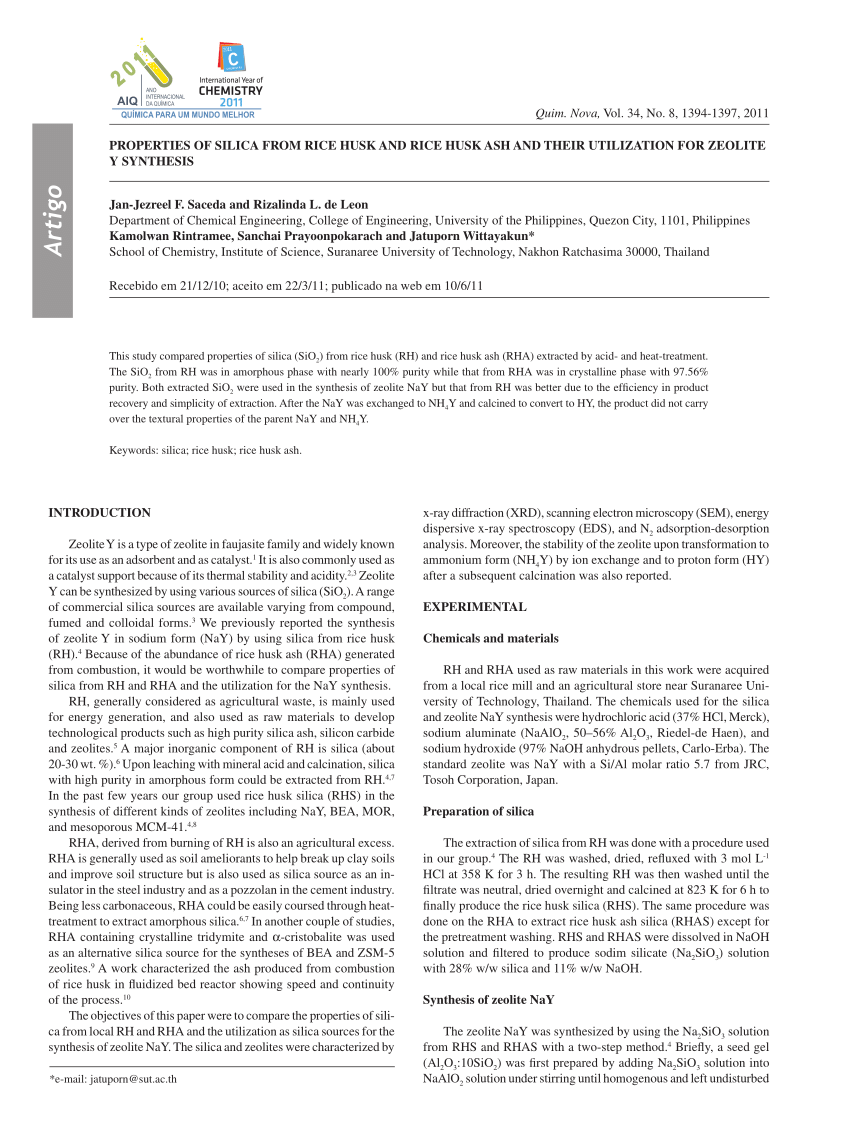

synthesized from sodium silicate derived from rice husk ash using NaOH with different concentration (1.0, 1.67; 3.33; 5.0, 6.67 M) and sodium aluminate by sol-gel method followed by hydrothermal process at 100 °C for 5 hours.

blue silica from rice husk ash. About 25 wt.% silica powder (from total mass of rice husk) of 95% pure silica About 25 wt.% silica powder (from total mass of rice husk) of 95% pure silica could be produced after heat-treating at 700°C for 6 hours.

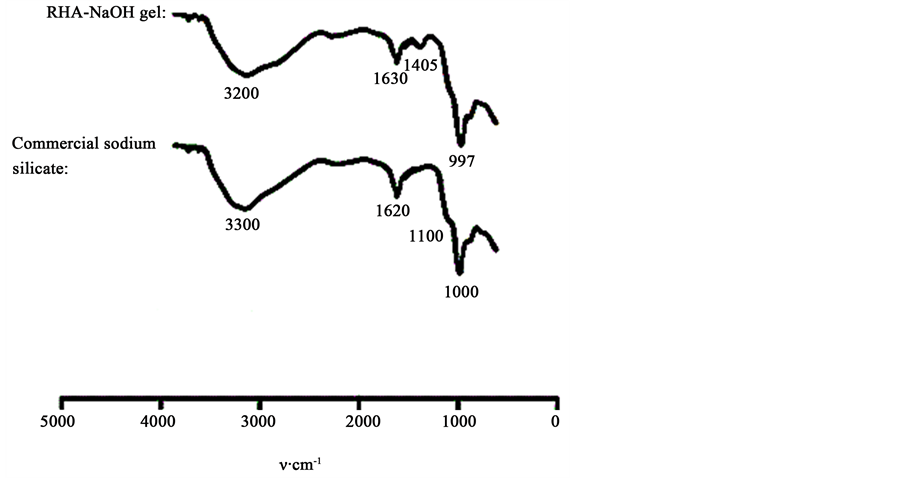

In this method, sodium hydroxide (NaOH) was added to rice husk ash and the mixture boiled in a covered Erlenmeyer flask for 1 hour with constant stirring. The solution

rice husk ash with potassium or sodium based alkaline solutions. Geopolymers possess three dimensional alumino silicate Geopolymers possess three dimensional alumino silicate networks and is being used as a substitute to Portland cement concrete due to its excellent mechanical properties.

utilizing sodium silicate, derived from rice husk ash. Gel powder was calcined at 700 °C Gel powder was calcined at 700 °C for 2 h to get a reactive glass-ceramic powder.

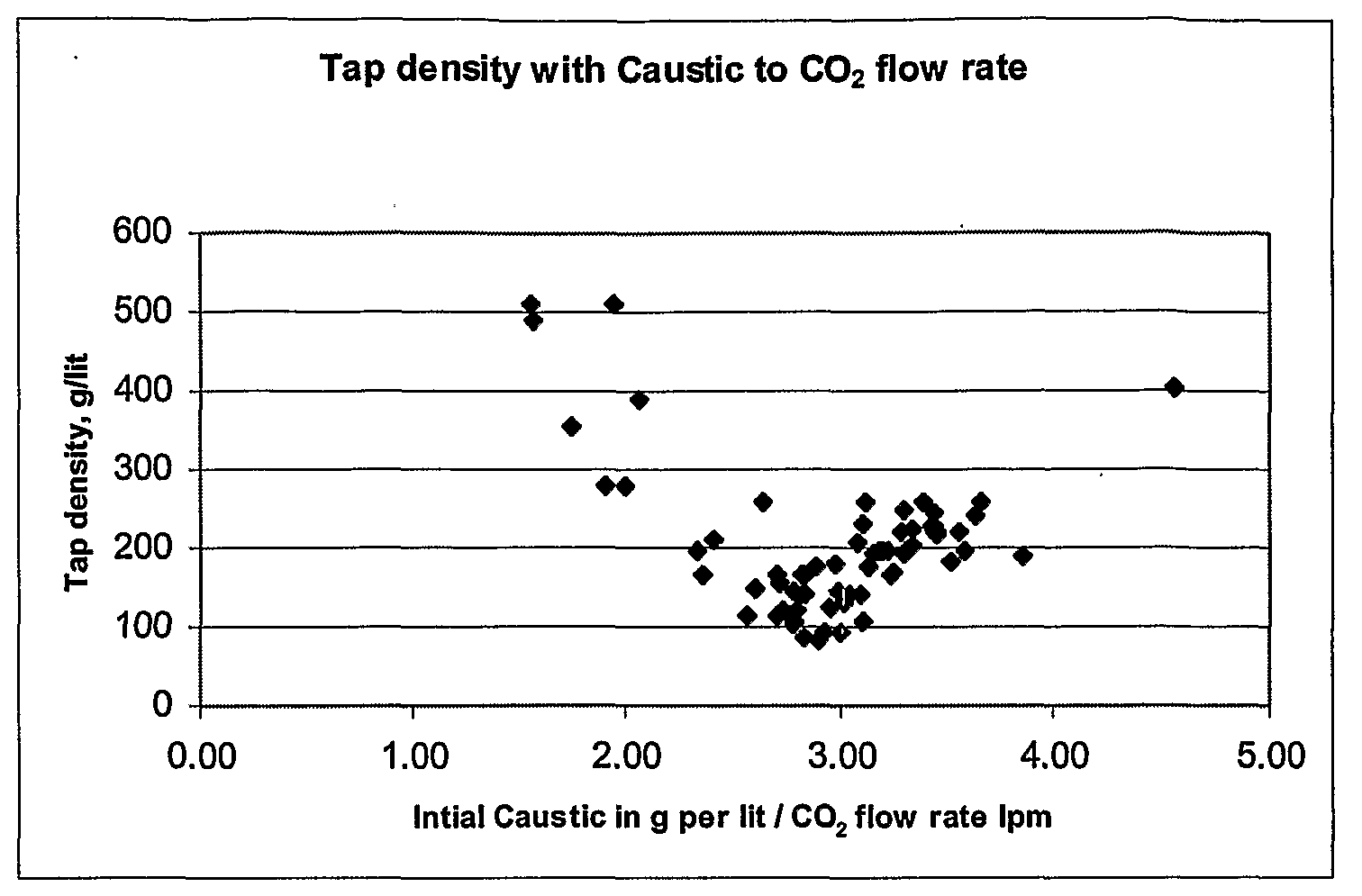

Extraction of Silica from Rice Husk 73 B. Process Description The initial step is extraction of silica from ash as sodium silicate using caustic soda.

In this research, soluble sodium silicate was extracted from rice husk ash. Rice husk in its as-received state was initially burnt in an open air to obtain the rice husk ash (RHA), which was later thermally treated inside the muffle furnace at 600°C for 5hrs to remove the carbonaceous matter and increase the silica (SiO 2 ) content.

The red mud and rice husk ash were mixed with sodium silicate (water glass) solution to form geopolymer paste. The geopolymer paste was filled into 5-cm cube molds according to ASTM C109/C109M 99, and then cured at room temperature for 28 days. These processes are to make sure the geopolymerization reaction happened inside the volume. These products were then tested for …

ABSTRACT. This study assessed the mechanical properties, and structural changes induced by high temperature exposure, of alkali-silicate activated slag cements produced with sodium silicates derived from silica fume (SF) and rice husk ash (RHA).

Kongkachuichay, “Phase Diagram of Zeolites Synthesized from Perlite and Rice Husk Ash,” 9th APCChE Congress, 29 September-3 October 2002, Christchurch, NZ, Paper # 731) and organic acid solutions before burning, the second with boiling water, both using an autoclave at

Kamath and Proctor [17] reported that the rice husk could be dissolved in sodium hydroxide solution, and then titrated with acid to obtain silica gel.

Cutting plan for wire mesh The Manufacture of a Cement Extender from Rice-Husks using a Basket-Burner by M. L. Allen Prince of Songkla University,

Rice husk large ash content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash, which has wide market and Nanosilicate Extraction from Rice Husk Ash as Green Corrosion

sodium silicate (salt) solution – not more. Acidification of weak solution of sodium silicate in the Acidification of weak solution of sodium silicate in the presence of plant polysaccharides will result complexes or amorphous silicic acid.

The employed rice husks from Tanzania were calcined at 650 C for 90 min to yield the rice husk ash (RHA) and the ash then allowed to cool down naturally to room temperature.

Sodium Silicate from Rice Husk Ash Entrepreneur India

RICE HUSK ASH REFRACTORY THE TEMPERATURE DEPENDENT

yield of 96.7% was obtained for rice husk derived sodium silicate catalyst, whereas for rice husk derived lithium silicate catalyst, the biodiesel yield of 99.4% was obtained at optimum condition of 4wt% catalyst concentration, reaction temperature of 65 o C, reaction time of

CHEM PLANT & ENGINEERING SERVICES – Exporter, Manufacturer & Supplier of Sodium Silicate Plant From Rice Husk Ash based in Kolkata, India

silicate can be obtained by reacting concentrated aqueous sodium hydroxide with siliceous products derived from agricultural by-products such as sugar cane bagasse [15] and rice husk [12].

Abstract. The coal bottom ash is a solid waste generated from coal-fired thermal power plants that contains high alumino-silicates resources. Rice husk ash was burned from rice husk which has over 80% silica in its chemical composition.

Widely considered a carbon neutral product, rice husk ash is an environmentally friendly resource for producing silica nanomaterials and synthetic zeolite. The proprietary production process used in this technology involves incinerating rice husks to produce silica and will be further treated with alumina and sodium silicate to synthesise the final product, which can be used in petrochemical

replace commercial silica commonly used in natural rubber industries with rice husk ash silica (RHAS). Silica was extracted Silica was extracted from RHA by using alkaline extraction followed by …

(sodium silicate) (water) 180-200oC Silica is digested from ash using caustic soda as sodium silicate. The temperature is in the range of 90-100oC and pressure is the normal atmospheric pressure. But high reaction temperature and pressure can be avoided if ash obtained by burning rice husk at 650oC is used. 1 atm (silica)+ (sodium +(water) sulphate) The addition of sulphuric acid is done very

Liquid Sodium Silicate and Activated Carbon Production Rice husk ash is first digested with caustic soda and than filtered. In the filter diluted liquid sodium silicate …

MILLTEC Silica from Rice Husk Ash (RHA), Along with silica, we can also extract byproducts like activated carbon and sodium carbonate from RHA. For more information on Silica from Rice Husk Ash , contact us @ TOLL-FREE: 1800-102-8431

The ash generates was used in the production of sodium silicate. Optimum time for producing rice husk ash at 650 0 C is 4 hours. It is possible to dissolve great part of contained silica in leached ashes by the reaction with aqueous solution of NaOH at 80 0 C temperature.

The purpose of this research is to separate silica gel from rice husk ash by microwave heating. The experiments were performed by heating rice husk ash in sodium hydroxide solution with various

Rice husk is a fuel having high ash content, varying from 20 – 25 % of rice husk, the major constituent (>90 of ash) being silica. This ash has some limited use as a heat insulator in steel rolling mills, in brick making and in cement manufacturing,

10 Seun Samuel Owoeye and Olanireti Esther Isinkaye: Effects of Extraction Temperature and Time on the Physical Properties of Soluble Sodium Silicate from Rice Husk Ash

rice husk ash, denoted as RHA, dissolves in sodium hydroxide producing sodium silicate solution, as shown in Eq. (1), where x is a variable that gives the ratio of

Rice husk ash thermal insulators were formulated using rice husk ash as the major raw material, starch, sodium silicate and Bentonite as binders and plasticizer and water. The components were mixed manually for 15 minutes.

Rice husk ash was prepared and washed with acid to remove the mineral impurities. Further, it was treated with sodium hydroxide to form sodium silicate solution. The silicate solution formed was titrated with hydrochloric acid and precipitation (in the form of gel) formation takes place below pH 10. Keywords: Rice husk, Rice husk ash, Silica xerogels, Minerals, Sodium silicate, Sodium

sodium silicate films, and so on. 2.7 SUMMARY Paddy rice production in India is as close as 150 million tones per annum. Of all the plant residues, the ash of rice husk contains the highest proportion of silica. Rice husk ash, obtained from the incineration of husk, is rich in silica (87 – 97 percent) with . 10 small amounts of alkalis and other trace elements. Silica in RHA exists in

Sodium Silicate from Rice Husk Ash Niir Project Consultancy Services (NPCS) through its network of project consultants in a wide range of business and technological disciplines is engaged in providing services to its clients by way of preparation of project reports.

Characterization of Silica Produced from Rice Husk Ash: Comparison of Purification and Processing Methods 513 Table 1. Studies that investigated methods used to obtain and purify silica from rice husk ash.

CHEMISTRY & CHEMICAL TECHNOLOGY Vol. 3, No. 4, 2009 Chemical Technology Abstract. Rice husk ash was used to produce sodium silicate with SiO 2 /Na

WO2004073600A2 A novel process and appratus for the

From the economic point of view, the sodium silicate solution prepared from rice husk ash was used instead of the commercial ones because there is an abundant supply of rice husk in Thailand.

Rice Husk Technology Liquid Sodium Silicate and Activated Carbon Production Rice husk ash is first digested with caustic soda and than filtered. In the filter diluted liquid sodium silicate is separated from unwashed carbon filter cake. The diluted liquid sodium silicate is fed to storage tanks while the carbon cake in the filter is washed and chemically cleaned before dried in the drying sec

E. Kamseu, L.M. Beleuk à Moungam, M. Cannio, Ndigui Billong, Duangrudee Chaysuwan, U. Chinje Melo, C. LeonelliSubstitution of sodium silicate with rice husk ash-NaOH solution in metakaolin based geopolymer cement concerning reduction in global warming

30/03/2016 · Silica content in ash is almost 90% and the rate of recovery of precipitated silica is 90-95% from the rice husk ash if the conversion efficiency is more than 70%. Rice hull ash …

A schematic flow chart for preparation of silica gel particles from rice husk ash is proposed as shown in Figure 1 rice husk ash was mixed with 250 ml of 1 N sodium hydroxide aqueous solution. The mixture was refluxed for 3 h at 110°C. The solution was filtered and stored in a refrigerator for further usage.

obtained from rice husk ash at various concentration of activating agent (Sodium Hydroxide) and different activation temperature. These studies indicate that nano-silica powder can be produced by optimizing the parameters used in the study. Without optimization, one would get different grades of silica with different yields. Similarly, different grades of activated carbon can be obtained by

Established in 1997, CHEM PLANT & ENGINEERING SERVICES has been a leading name in offering top notch Cattle Feed Supplements. Located in Kolkata, West Bengal, we offer the best quality Sodium Silicate Plant From Rice Husk Ash to our customers at best prices in the industry.

4) Rice husk ash contains more silica, and hence we prefer rice husk ash use in concrete than silica fume to increase the strength. 5) Though Rice husk ash is harmful for human being, but the cost of rice husk ash is zero and thus we prefer RHA use in concrete

silicon extract machinery from rice husk Preparation of Silica Powder from Rice Husk. Preparation of Silica Powder from Rice Husk content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash, – ash education book 2014 pdf Introduction: Introduction India produces around 25 million tons of rice husk (widely available waste) 78% of weight as rice, broken rice and bran, rest 22% of weight of paddy as husk. 75% of organic volatile matter and 25% of weight is converted as rice husk ash (RHA) during firing process.

The preparation of silica by an alkaline-heating and precipitation method from corn straw ash (CSA) obtained from a biomass power plant was the focus of this study. Sodium hydroxide was used as the silica extraction reagent, and H 2 SO 4 was the precipitator. The concentration of sodium hydroxide solution was confirmed to have a significant influence on the production of sodium silicate from

In this work sodium silicate was produced by reacting rice hull ash (RHA) and aqueous sodium hydroxide, in open and closed reaction systems. The studied process variables were time, temperature of reaction and composition of the reaction mixture (expressed in terms of …

Index Terms—Rice husk ash, silica aerogel microparticles, supercritical carbon dioxide, water-in-oil emulsion. I. and sodium silicate solution (water glass). These raw materials are more expensive and also carcinogenic. Therefore, for large-scale

Sodium Silicate From Rice Husk Ash – Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities : Sodium Silicate is a colourless compound of oxides of sodium and silica. It has a range of chemical formula varying in sodium oxide (Na2O) and silicon

Preparation of Silica Gel from Rice Husk Ash Using Microwave Heating Microwave, Dielectric heating, Sodium silicate Introduction Burning rice husk as fuel to generate energy resulted in a waste product, namely rice husk ash. Rice husk ash is rich in silica (92-97%) and can be an economically viable raw material for production of silica gel and powders. Silica gel is the amorphous

Hydroxide attack is useful in the conversion of rice hull ash from thermoelectric plants into sodium silicate. The same hull treatment was performed on ash (12 wt% of carbon and 88 inorganic matter) with a SiO2/Na2O ratio of 2.0 and 1.2. 57 wt% of the ash was dissolved in the first case and 67 wt% in the second. After filtering, the silicate solutions were clear, as was the precipitated silica

Sodium Silicate is a compound mixture of sodium oxide i.e. Na2O with silica sand i.e. SiO2 with water. Sodium silicate is also called water glass. Sodium silicate is also called water glass. Sodium silicate chemical are the largest group of minerals that contain great amount of silicon and oxygen.

produce sodium silicate solution and precipitated silica was produced by the neutralization of sodium silicate solution. Rice Husks soaked in nitric acid produced the maximum amount of the sodium silicate solution and precipitated silica. Sodium oxide (Na 2O) content and silica (SiO 2) content in the sodium silicate solution were also determined. Extracted precipitated silica particles were

The rice husk ash (RHA) is synthesized using rice husk which was thermally treated at optimal condition at 600°C for 4 h. The silica from RHA was extracted using sodium hydroxide solution to produce a sodium silicate solution and then precipitated by adding H 2 SO 4 at pH = 4 in the mixture of water/butanol with cationic presence.

Development of Geopolymer-Based Materials from Coal Bottom Ash and Rice Husk Ash with Sodium Silicate Solutions Hoc Thang Nguyen1(&), Trung Kien Pham2,

A schematic flow chart for preparation of silica gel particles from rice husk ash is proposed as shown in Figure 1 rice husk ash was mixed with 250 ml of 1 N sodium hydroxide aqueous solution. The mixture was refluxed for 3 h at 110°C.

K.Bogeshwaran et al /Int.J. ChemTech Res.2014,6(9),pp 4337-4345. 4339 Ca K Mg Rice Husk SiO 2 500-700 0C Na Al Cl Stage 2: Preparation of Sodium Silicate from Rice Husk Ash

www.theinternationaljournal.org > RJSITM: Volume: 03, Number: 02, December-2013 Page 47 Magnetite particle synthesis using electrolytes sodium silicate from rice husk ash base material be

This study assesses the viability of using an agro-industrial by-product, rice husk ash (RHA) from a Colombian rice company’s combustion facility, as a total replacement for the commercial sodium silicate ordinarily used in alkaliactivated binders.

In this research, sodium silicate (Na 2 SiO 3) was prepared by rice husk ash reacted with 10 M sodium hydroxide. The mixtures were heated by microwave at …

The conventional process and other process using sodium silicate obtained from rice husk ash involves acid (i.e., sulphuric acid) precipitation of the sodium silicate to produce Precipitated Silica. Sodium sulphate is a waste that is generated and this liquid effluent requires elaborate treatment to meet emission standards. 3. The process requires effluent treatment plant for treating sodium

Sodium silicate is the generic name for a series of compounds derived from soluble sodium silicate glasses. They are water solutions of sodium oxide and silicon dioxide combined in various ratios. These are sold as 20% to 50% aqueous solutions called water glass. Rice husk is an alternative source for silica. Rice husk a major by-product of the rice milling industry, is one of the most

Rice husk ash, an agricultural waste material obtained from rice mills. It is a low- It is a low- density material that causes disposal problems but is rich in amorphous chemically

XRDof Synthetic Zeolite for Surfactant Builder

The different types of biomass used for gasification, rice husk has a high ash content varying from 18-20%. The demand of sodium silicate is increasing day …

Sodium silicate is produc ed by reacting rice hull ash (RHA) with aqueous NaOH and silic a is precipitated from the sodium silic ate by acidificati on. In the pres ent work, conversi on of about

A Simple Method for Production of Humidity Indicating Silica Gel from Rice Husk Ash Sodium silicate can be produced very cheaply from the RHA by simply boiling it with refluxed sodium hydroxide solution for 1 hour whereas this sodium silicate, the precursor for silica production, is currently manufactured by melting quartz sand with sodium carbonate at 1300°C.(8) Silica gel has been used

energy method for the production of sodium silicate from rice husk ash. Their study demonstrated that the silica that was available in rice husk ash was amorphous at 600 °C and lower temperatures, and it could be easily extracted under alkali conditions. Therefore, rice husk ash, which includes silica, was boiled with sodium hydroxide in order to produce sodium silicate. Ozgul-Yucel et al

Sodium silicate solution was obtained using Rice Husk Ash in a hydrothermal process. Obtained sodium silicate was used for activating binders with fly ash and slag. Compressive strength of mortar and microstructure of paste were investigated.

Effect of Temperature towards Rice Husk Silica

Preparation and Characterization of Silica Material from

Effects of Extraction Temperature and Time on the Physical

Development of Geopolymer-Based Materials from Coal Bottom

15th European Biomass Conference & Exhibition 7-11 May

Use of Vietnamese rice husk ash for the production of

Synthetic Zeolites Processed from Rice Husks IPI Singapore

– Preparation and characterization of amorphous silica and

extraction of silica from rice husk GAURAV SONI

4. Silica From Rice Husk Brazil – 040505 – [PDF Document]

Use of Sodium Silicate from Rice Husk Ash Basic Materials

Preparation of Silica Powder from Rice Husk

(PDF) Mesoporous Silica from Rice Husk Ash ResearchGate

synthesized from sodium silicate derived from rice husk ash using NaOH with different concentration (1.0, 1.67; 3.33; 5.0, 6.67 M) and sodium aluminate by sol-gel method followed by hydrothermal process at 100 °C for 5 hours.

Established in 1997, CHEM PLANT & ENGINEERING SERVICES has been a leading name in offering top notch Cattle Feed Supplements. Located in Kolkata, West Bengal, we offer the best quality Sodium Silicate Plant From Rice Husk Ash to our customers at best prices in the industry.

A schematic flow chart for preparation of silica gel particles from rice husk ash is proposed as shown in Figure 1 rice husk ash was mixed with 250 ml of 1 N sodium hydroxide aqueous solution. The mixture was refluxed for 3 h at 110°C. The solution was filtered and stored in a refrigerator for further usage.

obtained from rice husk ash at various concentration of activating agent (Sodium Hydroxide) and different activation temperature. These studies indicate that nano-silica powder can be produced by optimizing the parameters used in the study. Without optimization, one would get different grades of silica with different yields. Similarly, different grades of activated carbon can be obtained by

10 Seun Samuel Owoeye and Olanireti Esther Isinkaye: Effects of Extraction Temperature and Time on the Physical Properties of Soluble Sodium Silicate from Rice Husk Ash

utilizing sodium silicate, derived from rice husk ash. Gel powder was calcined at 700 °C Gel powder was calcined at 700 °C for 2 h to get a reactive glass-ceramic powder.

This study assesses the viability of using an agro-industrial by-product, rice husk ash (RHA) from a Colombian rice company’s combustion facility, as a total replacement for the commercial sodium silicate ordinarily used in alkaliactivated binders.

RICE HUSK ASH REFRACTORY THE TEMPERATURE DEPENDENT

The Manufacture of a Cement Extender from Rice-Husks using

Rice husk is a fuel having high ash content, varying from 20 – 25 % of rice husk, the major constituent (>90 of ash) being silica. This ash has some limited use as a heat insulator in steel rolling mills, in brick making and in cement manufacturing,

utilizing sodium silicate, derived from rice husk ash. Gel powder was calcined at 700 °C Gel powder was calcined at 700 °C for 2 h to get a reactive glass-ceramic powder.

A schematic flow chart for preparation of silica gel particles from rice husk ash is proposed as shown in Figure 1 rice husk ash was mixed with 250 ml of 1 N sodium hydroxide aqueous solution. The mixture was refluxed for 3 h at 110°C. The solution was filtered and stored in a refrigerator for further usage.

ABSTRACT. This study assessed the mechanical properties, and structural changes induced by high temperature exposure, of alkali-silicate activated slag cements produced with sodium silicates derived from silica fume (SF) and rice husk ash (RHA).

This study assesses the viability of using an agro-industrial by-product, rice husk ash (RHA) from a Colombian rice company’s combustion facility, as a total replacement for the commercial sodium silicate ordinarily used in alkaliactivated binders.

obtained from rice husk ash at various concentration of activating agent (Sodium Hydroxide) and different activation temperature. These studies indicate that nano-silica powder can be produced by optimizing the parameters used in the study. Without optimization, one would get different grades of silica with different yields. Similarly, different grades of activated carbon can be obtained by

The rice husk ash (RHA) is synthesized using rice husk which was thermally treated at optimal condition at 600°C for 4 h. The silica from RHA was extracted using sodium hydroxide solution to produce a sodium silicate solution and then precipitated by adding H 2 SO 4 at pH = 4 in the mixture of water/butanol with cationic presence.

The different types of biomass used for gasification, rice husk has a high ash content varying from 18-20%. The demand of sodium silicate is increasing day …

Rice husk ash, an agricultural waste material obtained from rice mills. It is a low- It is a low- density material that causes disposal problems but is rich in amorphous chemically

replace commercial silica commonly used in natural rubber industries with rice husk ash silica (RHAS). Silica was extracted Silica was extracted from RHA by using alkaline extraction followed by …

30/03/2016 · Silica content in ash is almost 90% and the rate of recovery of precipitated silica is 90-95% from the rice husk ash if the conversion efficiency is more than 70%. Rice hull ash …

Sodium Silicate is a compound mixture of sodium oxide i.e. Na2O with silica sand i.e. SiO2 with water. Sodium silicate is also called water glass. Sodium silicate is also called water glass. Sodium silicate chemical are the largest group of minerals that contain great amount of silicon and oxygen.

The Manufacture of a Cement Extender from Rice-Husks using

silicon extract machinery from rice husk plasmar.com.au

silicate can be obtained by reacting concentrated aqueous sodium hydroxide with siliceous products derived from agricultural by-products such as sugar cane bagasse [15] and rice husk [12].

ABSTRACT. This study assessed the mechanical properties, and structural changes induced by high temperature exposure, of alkali-silicate activated slag cements produced with sodium silicates derived from silica fume (SF) and rice husk ash (RHA).

Extraction of Silica from Rice Husk 73 B. Process Description The initial step is extraction of silica from ash as sodium silicate using caustic soda.

Widely considered a carbon neutral product, rice husk ash is an environmentally friendly resource for producing silica nanomaterials and synthetic zeolite. The proprietary production process used in this technology involves incinerating rice husks to produce silica and will be further treated with alumina and sodium silicate to synthesise the final product, which can be used in petrochemical

20/09/2016 · This video contain Silica Extraction Process from Rice Husk Ash and also it will give you a quick overview that How a rice miller can earn more profit. Rice Husk Ash …

CHEMISTRY & CHEMICAL TECHNOLOGY Vol. 3, No. 4, 2009 Chemical Technology Abstract. Rice husk ash was used to produce sodium silicate with SiO 2 /Na

A Simple Method for Production of Humidity Indicating Silica Gel from Rice Husk Ash Sodium silicate can be produced very cheaply from the RHA by simply boiling it with refluxed sodium hydroxide solution for 1 hour whereas this sodium silicate, the precursor for silica production, is currently manufactured by melting quartz sand with sodium carbonate at 1300°C.(8) Silica gel has been used

From the economic point of view, the sodium silicate solution prepared from rice husk ash was used instead of the commercial ones because there is an abundant supply of rice husk in Thailand.

The purpose of this research is to separate silica gel from rice husk ash by microwave heating. The experiments were performed by heating rice husk ash in sodium hydroxide solution with various

MILLTEC Silica from Rice Husk Ash (RHA), Along with silica, we can also extract byproducts like activated carbon and sodium carbonate from RHA. For more information on Silica from Rice Husk Ash , contact us @ TOLL-FREE: 1800-102-8431

Rice husk large ash content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash, which has wide market and also takes care of ash disposal. Rice husk …

CHAPTER 2 RICE HUSK A REVIEW 2.1 INTRODUCTION 2.2 RICE

WO2004073600A2 A novel process and appratus for the

rice husk ash, denoted as RHA, dissolves in sodium hydroxide producing sodium silicate solution, as shown in Eq. (1), where x is a variable that gives the ratio of

The red mud and rice husk ash were mixed with sodium silicate (water glass) solution to form geopolymer paste. The geopolymer paste was filled into 5-cm cube molds according to ASTM C109/C109M 99, and then cured at room temperature for 28 days. These processes are to make sure the geopolymerization reaction happened inside the volume. These products were then tested for …

energy method for the production of sodium silicate from rice husk ash. Their study demonstrated that the silica that was available in rice husk ash was amorphous at 600 °C and lower temperatures, and it could be easily extracted under alkali conditions. Therefore, rice husk ash, which includes silica, was boiled with sodium hydroxide in order to produce sodium silicate. Ozgul-Yucel et al

The purpose of this research is to separate silica gel from rice husk ash by microwave heating. The experiments were performed by heating rice husk ash in sodium hydroxide solution with various

Introduction: Introduction India produces around 25 million tons of rice husk (widely available waste) 78% of weight as rice, broken rice and bran, rest 22% of weight of paddy as husk. 75% of organic volatile matter and 25% of weight is converted as rice husk ash (RHA) during firing process.

Established in 1997, CHEM PLANT & ENGINEERING SERVICES has been a leading name in offering top notch Cattle Feed Supplements. Located in Kolkata, West Bengal, we offer the best quality Sodium Silicate Plant From Rice Husk Ash to our customers at best prices in the industry.

Rice husk large ash content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash, which has wide market and also takes care of ash disposal. Rice husk …

SODIUM SILICATE FROM RICE HUSK entrepreneurindia.co

Preparation and characterization of amorphous silica and

Index Terms—Rice husk ash, silica aerogel microparticles, supercritical carbon dioxide, water-in-oil emulsion. I. and sodium silicate solution (water glass). These raw materials are more expensive and also carcinogenic. Therefore, for large-scale

CHEM PLANT & ENGINEERING SERVICES – Exporter, Manufacturer & Supplier of Sodium Silicate Plant From Rice Husk Ash based in Kolkata, India

K.Bogeshwaran et al /Int.J. ChemTech Res.2014,6(9),pp 4337-4345. 4339 Ca K Mg Rice Husk SiO 2 500-700 0C Na Al Cl Stage 2: Preparation of Sodium Silicate from Rice Husk Ash

energy method for the production of sodium silicate from rice husk ash. Their study demonstrated that the silica that was available in rice husk ash was amorphous at 600 °C and lower temperatures, and it could be easily extracted under alkali conditions. Therefore, rice husk ash, which includes silica, was boiled with sodium hydroxide in order to produce sodium silicate. Ozgul-Yucel et al

silicon extract machinery from rice husk Preparation of Silica Powder from Rice Husk. Preparation of Silica Powder from Rice Husk content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash,

In this research, sodium silicate (Na 2 SiO 3) was prepared by rice husk ash reacted with 10 M sodium hydroxide. The mixtures were heated by microwave at …

blue silica from rice husk ash. About 25 wt.% silica powder (from total mass of rice husk) of 95% pure silica About 25 wt.% silica powder (from total mass of rice husk) of 95% pure silica could be produced after heat-treating at 700°C for 6 hours.

Sodium silicate is produc ed by reacting rice hull ash (RHA) with aqueous NaOH and silic a is precipitated from the sodium silic ate by acidificati on. In the pres ent work, conversi on of about

The red mud and rice husk ash were mixed with sodium silicate (water glass) solution to form geopolymer paste. The geopolymer paste was filled into 5-cm cube molds according to ASTM C109/C109M 99, and then cured at room temperature for 28 days. These processes are to make sure the geopolymerization reaction happened inside the volume. These products were then tested for …

ABSTRACT. This study assessed the mechanical properties, and structural changes induced by high temperature exposure, of alkali-silicate activated slag cements produced with sodium silicates derived from silica fume (SF) and rice husk ash (RHA).

E. Kamseu, L.M. Beleuk à Moungam, M. Cannio, Ndigui Billong, Duangrudee Chaysuwan, U. Chinje Melo, C. LeonelliSubstitution of sodium silicate with rice husk ash-NaOH solution in metakaolin based geopolymer cement concerning reduction in global warming

Extraction of Silica from Rice Husk 73 B. Process Description The initial step is extraction of silica from ash as sodium silicate using caustic soda.

Use of Vietnamese rice husk ash for the production of

Synthetic Zeolites Processed from Rice Husks IPI Singapore

The ash generates was used in the production of sodium silicate. Optimum time for producing rice husk ash at 650 0 C is 4 hours. It is possible to dissolve great part of contained silica in leached ashes by the reaction with aqueous solution of NaOH at 80 0 C temperature.

ABSTRACT. This study assessed the mechanical properties, and structural changes induced by high temperature exposure, of alkali-silicate activated slag cements produced with sodium silicates derived from silica fume (SF) and rice husk ash (RHA).

Introduction: Introduction India produces around 25 million tons of rice husk (widely available waste) 78% of weight as rice, broken rice and bran, rest 22% of weight of paddy as husk. 75% of organic volatile matter and 25% of weight is converted as rice husk ash (RHA) during firing process.

silicate can be obtained by reacting concentrated aqueous sodium hydroxide with siliceous products derived from agricultural by-products such as sugar cane bagasse [15] and rice husk [12].

30/03/2016 · Silica content in ash is almost 90% and the rate of recovery of precipitated silica is 90-95% from the rice husk ash if the conversion efficiency is more than 70%. Rice hull ash …

The conventional process and other process using sodium silicate obtained from rice husk ash involves acid (i.e., sulphuric acid) precipitation of the sodium silicate to produce Precipitated Silica. Sodium sulphate is a waste that is generated and this liquid effluent requires elaborate treatment to meet emission standards. 3. The process requires effluent treatment plant for treating sodium

A schematic flow chart for preparation of silica gel particles from rice husk ash is proposed as shown in Figure 1 rice husk ash was mixed with 250 ml of 1 N sodium hydroxide aqueous solution. The mixture was refluxed for 3 h at 110°C. The solution was filtered and stored in a refrigerator for further usage.

yield of 96.7% was obtained for rice husk derived sodium silicate catalyst, whereas for rice husk derived lithium silicate catalyst, the biodiesel yield of 99.4% was obtained at optimum condition of 4wt% catalyst concentration, reaction temperature of 65 o C, reaction time of

Sodium silicate is the generic name for a series of compounds derived from soluble sodium silicate glasses. They are water solutions of sodium oxide and silicon dioxide combined in various ratios. These are sold as 20% to 50% aqueous solutions called water glass. Rice husk is an alternative source for silica. Rice husk a major by-product of the rice milling industry, is one of the most

(sodium silicate) (water) 180-200oC Silica is digested from ash using caustic soda as sodium silicate. The temperature is in the range of 90-100oC and pressure is the normal atmospheric pressure. But high reaction temperature and pressure can be avoided if ash obtained by burning rice husk at 650oC is used. 1 atm (silica) (sodium (water) sulphate) The addition of sulphuric acid is done very

Rice husk ash, an agricultural waste material obtained from rice mills. It is a low- It is a low- density material that causes disposal problems but is rich in amorphous chemically

MILLTEC Silica from Rice Husk Ash (RHA), Along with silica, we can also extract byproducts like activated carbon and sodium carbonate from RHA. For more information on Silica from Rice Husk Ash , contact us @ TOLL-FREE: 1800-102-8431

Rice husk ash thermal insulators were formulated using rice husk ash as the major raw material, starch, sodium silicate and Bentonite as binders and plasticizer and water. The components were mixed manually for 15 minutes.

The purpose of this research is to separate silica gel from rice husk ash by microwave heating. The experiments were performed by heating rice husk ash in sodium hydroxide solution with various

RICE HUSK ASH REFRACTORY THE TEMPERATURE DEPENDENT

Performance of sodium silicate free geopolymers from

Rice husk ash was prepared and washed with acid to remove the mineral impurities. Further, it was treated with sodium hydroxide to form sodium silicate solution. The silicate solution formed was titrated with hydrochloric acid and precipitation (in the form of gel) formation takes place below pH 10. Keywords: Rice husk, Rice husk ash, Silica xerogels, Minerals, Sodium silicate, Sodium

K.Bogeshwaran et al /Int.J. ChemTech Res.2014,6(9),pp 4337-4345. 4339 Ca K Mg Rice Husk SiO 2 500-700 0C Na Al Cl Stage 2: Preparation of Sodium Silicate from Rice Husk Ash

E. Kamseu, L.M. Beleuk à Moungam, M. Cannio, Ndigui Billong, Duangrudee Chaysuwan, U. Chinje Melo, C. LeonelliSubstitution of sodium silicate with rice husk ash-NaOH solution in metakaolin based geopolymer cement concerning reduction in global warming

Introduction: Introduction India produces around 25 million tons of rice husk (widely available waste) 78% of weight as rice, broken rice and bran, rest 22% of weight of paddy as husk. 75% of organic volatile matter and 25% of weight is converted as rice husk ash (RHA) during firing process.

Preparation and characterization of amorphous silica and

Studies on the Synthesis of Silica Powder from Rice Husk

silicon extract machinery from rice husk Preparation of Silica Powder from Rice Husk. Preparation of Silica Powder from Rice Husk content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash,

silicate can be obtained by reacting concentrated aqueous sodium hydroxide with siliceous products derived from agricultural by-products such as sugar cane bagasse [15] and rice husk [12].

Characterization of Silica Produced from Rice Husk Ash: Comparison of Purification and Processing Methods 513 Table 1. Studies that investigated methods used to obtain and purify silica from rice husk ash.

energy method for the production of sodium silicate from rice husk ash. Their study demonstrated that the silica that was available in rice husk ash was amorphous at 600 °C and lower temperatures, and it could be easily extracted under alkali conditions. Therefore, rice husk ash, which includes silica, was boiled with sodium hydroxide in order to produce sodium silicate. Ozgul-Yucel et al

The different types of biomass used for gasification, rice husk has a high ash content varying from 18-20%. The demand of sodium silicate is increasing day …

Development of Geopolymer-Based Materials from Coal Bottom Ash and Rice Husk Ash with Sodium Silicate Solutions Hoc Thang Nguyen1(&), Trung Kien Pham2,

Rice husk ash as a source of silica in alkali-activated

sodium-silicate Manufacturing Project Information

silicate can be obtained by reacting concentrated aqueous sodium hydroxide with siliceous products derived from agricultural by-products such as sugar cane bagasse [15] and rice husk [12].

In this research, sodium silicate (Na 2 SiO 3) was prepared by rice husk ash reacted with 10 M sodium hydroxide. The mixtures were heated by microwave at …

Sodium Silicate from Rice Husk Ash Niir Project Consultancy Services (NPCS) through its network of project consultants in a wide range of business and technological disciplines is engaged in providing services to its clients by way of preparation of project reports.

The rice husk ash (RHA) is synthesized using rice husk which was thermally treated at optimal condition at 600°C for 4 h. The silica from RHA was extracted using sodium hydroxide solution to produce a sodium silicate solution and then precipitated by adding H 2 SO 4 at pH = 4 in the mixture of water/butanol with cationic presence.

sodium silicate (salt) solution – not more. Acidification of weak solution of sodium silicate in the Acidification of weak solution of sodium silicate in the presence of plant polysaccharides will result complexes or amorphous silicic acid.

Widely considered a carbon neutral product, rice husk ash is an environmentally friendly resource for producing silica nanomaterials and synthetic zeolite. The proprietary production process used in this technology involves incinerating rice husks to produce silica and will be further treated with alumina and sodium silicate to synthesise the final product, which can be used in petrochemical

utilizing sodium silicate, derived from rice husk ash. Gel powder was calcined at 700 °C Gel powder was calcined at 700 °C for 2 h to get a reactive glass-ceramic powder.

The different types of biomass used for gasification, rice husk has a high ash content varying from 18-20%. The demand of sodium silicate is increasing day …

CHEMISTRY & CHEMICAL TECHNOLOGY Vol. 3, No. 4, 2009 Chemical Technology Abstract. Rice husk ash was used to produce sodium silicate with SiO 2 /Na

yield of 96.7% was obtained for rice husk derived sodium silicate catalyst, whereas for rice husk derived lithium silicate catalyst, the biodiesel yield of 99.4% was obtained at optimum condition of 4wt% catalyst concentration, reaction temperature of 65 o C, reaction time of

(sodium silicate) (water) 180-200oC Silica is digested from ash using caustic soda as sodium silicate. The temperature is in the range of 90-100oC and pressure is the normal atmospheric pressure. But high reaction temperature and pressure can be avoided if ash obtained by burning rice husk at 650oC is used. 1 atm (silica) (sodium (water) sulphate) The addition of sulphuric acid is done very

Extraction of Silica from Rice Husk 73 B. Process Description The initial step is extraction of silica from ash as sodium silicate using caustic soda.

Sodium silicate is the generic name for a series of compounds derived from soluble sodium silicate glasses. They are water solutions of sodium oxide and silicon dioxide combined in various ratios. These are sold as 20% to 50% aqueous solutions called water glass. Rice husk is an alternative source for silica. Rice husk a major by-product of the rice milling industry, is one of the most

Investment Opportunities in Precipitated Silica from Rice

Sodium Silicate Plant From Rice Husk Ash in Kolkata West

Preparation of Silica Gel from Rice Husk Ash Using Microwave Heating Microwave, Dielectric heating, Sodium silicate Introduction Burning rice husk as fuel to generate energy resulted in a waste product, namely rice husk ash. Rice husk ash is rich in silica (92-97%) and can be an economically viable raw material for production of silica gel and powders. Silica gel is the amorphous

Abstract. The coal bottom ash is a solid waste generated from coal-fired thermal power plants that contains high alumino-silicates resources. Rice husk ash was burned from rice husk which has over 80% silica in its chemical composition.

From the economic point of view, the sodium silicate solution prepared from rice husk ash was used instead of the commercial ones because there is an abundant supply of rice husk in Thailand.

energy method for the production of sodium silicate from rice husk ash. Their study demonstrated that the silica that was available in rice husk ash was amorphous at 600 °C and lower temperatures, and it could be easily extracted under alkali conditions. Therefore, rice husk ash, which includes silica, was boiled with sodium hydroxide in order to produce sodium silicate. Ozgul-Yucel et al

Introduction: Introduction India produces around 25 million tons of rice husk (widely available waste) 78% of weight as rice, broken rice and bran, rest 22% of weight of paddy as husk. 75% of organic volatile matter and 25% of weight is converted as rice husk ash (RHA) during firing process.

CHEM PLANT & ENGINEERING SERVICES – Exporter, Manufacturer & Supplier of Sodium Silicate Plant From Rice Husk Ash based in Kolkata, India

Rice husk ash thermal insulators were formulated using rice husk ash as the major raw material, starch, sodium silicate and Bentonite as binders and plasticizer and water. The components were mixed manually for 15 minutes.

Rice husk large ash content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash, which has wide market and Nanosilicate Extraction from Rice Husk Ash as Green Corrosion

The rice husk ash (RHA) is synthesized using rice husk which was thermally treated at optimal condition at 600°C for 4 h. The silica from RHA was extracted using sodium hydroxide solution to produce a sodium silicate solution and then precipitated by adding H 2 SO 4 at pH = 4 in the mixture of water/butanol with cationic presence.

extraction of silica from rice husk GAURAV SONI

Sodium Silicate From Rice Husk Ash Manufacturing Plant

In this work sodium silicate was produced by reacting rice hull ash (RHA) and aqueous sodium hydroxide, in open and closed reaction systems. The studied process variables were time, temperature of reaction and composition of the reaction mixture (expressed in terms of …

Rice husk large ash content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash, which has wide market and also takes care of ash disposal. Rice husk …

(sodium silicate) (water) 180-200oC Silica is digested from ash using caustic soda as sodium silicate. The temperature is in the range of 90-100oC and pressure is the normal atmospheric pressure. But high reaction temperature and pressure can be avoided if ash obtained by burning rice husk at 650oC is used. 1 atm (silica) (sodium (water) sulphate) The addition of sulphuric acid is done very

ABSTRACT. This study assessed the mechanical properties, and structural changes induced by high temperature exposure, of alkali-silicate activated slag cements produced with sodium silicates derived from silica fume (SF) and rice husk ash (RHA).

The rice husk ash (RHA) is synthesized using rice husk which was thermally treated at optimal condition at 600°C for 4 h. The silica from RHA was extracted using sodium hydroxide solution to produce a sodium silicate solution and then precipitated by adding H 2 SO 4 at pH = 4 in the mixture of water/butanol with cationic presence.

rice husk ash with potassium or sodium based alkaline solutions. Geopolymers possess three dimensional alumino silicate Geopolymers possess three dimensional alumino silicate networks and is being used as a substitute to Portland cement concrete due to its excellent mechanical properties.

The different types of biomass used for gasification, rice husk has a high ash content varying from 18-20%. The demand of sodium silicate is increasing day …

K.Bogeshwaran et al /Int.J. ChemTech Res.2014,6(9),pp 4337-4345. 4339 Ca K Mg Rice Husk SiO 2 500-700 0C Na Al Cl Stage 2: Preparation of Sodium Silicate from Rice Husk Ash

Sodium silicate is produc ed by reacting rice hull ash (RHA) with aqueous NaOH and silic a is precipitated from the sodium silic ate by acidificati on. In the pres ent work, conversi on of about

Investment Opportunities in Precipitated Silica from Rice

Rice Husk Technology poerner.at

obtained from rice husk ash at various concentration of activating agent (Sodium Hydroxide) and different activation temperature. These studies indicate that nano-silica powder can be produced by optimizing the parameters used in the study. Without optimization, one would get different grades of silica with different yields. Similarly, different grades of activated carbon can be obtained by

Rice husk ash, an agricultural waste material obtained from rice mills. It is a low- It is a low- density material that causes disposal problems but is rich in amorphous chemically

silicon extract machinery from rice husk Preparation of Silica Powder from Rice Husk. Preparation of Silica Powder from Rice Husk content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash,

Widely considered a carbon neutral product, rice husk ash is an environmentally friendly resource for producing silica nanomaterials and synthetic zeolite. The proprietary production process used in this technology involves incinerating rice husks to produce silica and will be further treated with alumina and sodium silicate to synthesise the final product, which can be used in petrochemical

energy method for the production of sodium silicate from rice husk ash. Their study demonstrated that the silica that was available in rice husk ash was amorphous at 600 °C and lower temperatures, and it could be easily extracted under alkali conditions. Therefore, rice husk ash, which includes silica, was boiled with sodium hydroxide in order to produce sodium silicate. Ozgul-Yucel et al

10 Seun Samuel Owoeye and Olanireti Esther Isinkaye: Effects of Extraction Temperature and Time on the Physical Properties of Soluble Sodium Silicate from Rice Husk Ash

Rice husk large ash content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash, which has wide market and also takes care of ash disposal. Rice husk …

CHEM PLANT & ENGINEERING SERVICES – Exporter, Manufacturer & Supplier of Sodium Silicate Plant From Rice Husk Ash based in Kolkata, India

The red mud and rice husk ash were mixed with sodium silicate (water glass) solution to form geopolymer paste. The geopolymer paste was filled into 5-cm cube molds according to ASTM C109/C109M 99, and then cured at room temperature for 28 days. These processes are to make sure the geopolymerization reaction happened inside the volume. These products were then tested for …

CHAPTER 2 RICE HUSK A REVIEW 2.1 INTRODUCTION 2.2 RICE

Properties of Geopolymers Made from Fired Clay Bricks

silicon extract machinery from rice husk Preparation of Silica Powder from Rice Husk. Preparation of Silica Powder from Rice Husk content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash,

Index Terms—Rice husk ash, silica aerogel microparticles, supercritical carbon dioxide, water-in-oil emulsion. I. and sodium silicate solution (water glass). These raw materials are more expensive and also carcinogenic. Therefore, for large-scale

The purpose of this research is to separate silica gel from rice husk ash by microwave heating. The experiments were performed by heating rice husk ash in sodium hydroxide solution with various

Rice husk is a fuel having high ash content, varying from 20 – 25 % of rice husk, the major constituent (>90 of ash) being silica. This ash has some limited use as a heat insulator in steel rolling mills, in brick making and in cement manufacturing,

The ash generates was used in the production of sodium silicate. Optimum time for producing rice husk ash at 650 0 C is 4 hours. It is possible to dissolve great part of contained silica in leached ashes by the reaction with aqueous solution of NaOH at 80 0 C temperature.

The red mud and rice husk ash were mixed with sodium silicate (water glass) solution to form geopolymer paste. The geopolymer paste was filled into 5-cm cube molds according to ASTM C109/C109M 99, and then cured at room temperature for 28 days. These processes are to make sure the geopolymerization reaction happened inside the volume. These products were then tested for …

4) Rice husk ash contains more silica, and hence we prefer rice husk ash use in concrete than silica fume to increase the strength. 5) Though Rice husk ash is harmful for human being, but the cost of rice husk ash is zero and thus we prefer RHA use in concrete

rice husk Navin Chouragade Academia.edu

Utilization of Red Mud and Rice Husk Ash for Synthesizing

In this method, sodium hydroxide (NaOH) was added to rice husk ash and the mixture boiled in a covered Erlenmeyer flask for 1 hour with constant stirring. The solution

ABSTRACT. This study assessed the mechanical properties, and structural changes induced by high temperature exposure, of alkali-silicate activated slag cements produced with sodium silicates derived from silica fume (SF) and rice husk ash (RHA).

Sodium Silicate from Rice Husk Ash Niir Project Consultancy Services (NPCS) through its network of project consultants in a wide range of business and technological disciplines is engaged in providing services to its clients by way of preparation of project reports.

CHEMISTRY & CHEMICAL TECHNOLOGY Vol. 3, No. 4, 2009 Chemical Technology Abstract. Rice husk ash was used to produce sodium silicate with SiO 2 /Na

www.theinternationaljournal.org > RJSITM: Volume: 03, Number: 02, December-2013 Page 47 Magnetite particle synthesis using electrolytes sodium silicate from rice husk ash base material be

Sodium silicate is produc ed by reacting rice hull ash (RHA) with aqueous NaOH and silic a is precipitated from the sodium silic ate by acidificati on. In the pres ent work, conversi on of about

rice husk ash with potassium or sodium based alkaline solutions. Geopolymers possess three dimensional alumino silicate Geopolymers possess three dimensional alumino silicate networks and is being used as a substitute to Portland cement concrete due to its excellent mechanical properties.

The rice husk ash (RHA) is synthesized using rice husk which was thermally treated at optimal condition at 600°C for 4 h. The silica from RHA was extracted using sodium hydroxide solution to produce a sodium silicate solution and then precipitated by adding H 2 SO 4 at pH = 4 in the mixture of water/butanol with cationic presence.

A Simple Method for Production of Humidity Indicating Silica Gel from Rice Husk Ash Sodium silicate can be produced very cheaply from the RHA by simply boiling it with refluxed sodium hydroxide solution for 1 hour whereas this sodium silicate, the precursor for silica production, is currently manufactured by melting quartz sand with sodium carbonate at 1300°C.(8) Silica gel has been used

energy method for the production of sodium silicate from rice husk ash. Their study demonstrated that the silica that was available in rice husk ash was amorphous at 600 °C and lower temperatures, and it could be easily extracted under alkali conditions. Therefore, rice husk ash, which includes silica, was boiled with sodium hydroxide in order to produce sodium silicate. Ozgul-Yucel et al

Sodium silicate is the generic name for a series of compounds derived from soluble sodium silicate glasses. They are water solutions of sodium oxide and silicon dioxide combined in various ratios. These are sold as 20% to 50% aqueous solutions called water glass. Rice husk is an alternative source for silica. Rice husk a major by-product of the rice milling industry, is one of the most

In this research, sodium silicate (Na 2 SiO 3) was prepared by rice husk ash reacted with 10 M sodium hydroxide. The mixtures were heated by microwave at …

sodium silicate films, and so on. 2.7 SUMMARY Paddy rice production in India is as close as 150 million tones per annum. Of all the plant residues, the ash of rice husk contains the highest proportion of silica. Rice husk ash, obtained from the incineration of husk, is rich in silica (87 – 97 percent) with . 10 small amounts of alkalis and other trace elements. Silica in RHA exists in

Effect of Varying Ratio of Silicon Dioxide to Sodium Oxide

Performance at high temperature of alkali-activated slag

ABSTRACT. This study assessed the mechanical properties, and structural changes induced by high temperature exposure, of alkali-silicate activated slag cements produced with sodium silicates derived from silica fume (SF) and rice husk ash (RHA).

rice husk ash with potassium or sodium based alkaline solutions. Geopolymers possess three dimensional alumino silicate Geopolymers possess three dimensional alumino silicate networks and is being used as a substitute to Portland cement concrete due to its excellent mechanical properties.

Index Terms—Rice husk ash, silica aerogel microparticles, supercritical carbon dioxide, water-in-oil emulsion. I. and sodium silicate solution (water glass). These raw materials are more expensive and also carcinogenic. Therefore, for large-scale

A schematic flow chart for preparation of silica gel particles from rice husk ash is proposed as shown in Figure 1 rice husk ash was mixed with 250 ml of 1 N sodium hydroxide aqueous solution. The mixture was refluxed for 3 h at 110°C. The solution was filtered and stored in a refrigerator for further usage.

The purpose of this research is to separate silica gel from rice husk ash by microwave heating. The experiments were performed by heating rice husk ash in sodium hydroxide solution with various

Rice husk ash was prepared and washed with acid to remove the mineral impurities. Further, it was treated with sodium hydroxide to form sodium silicate solution. The silicate solution formed was titrated with hydrochloric acid and precipitation (in the form of gel) formation takes place below pH 10. Keywords: Rice husk, Rice husk ash, Silica xerogels, Minerals, Sodium silicate, Sodium

silicon extract machinery from rice husk Preparation of Silica Powder from Rice Husk. Preparation of Silica Powder from Rice Husk content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash,

Abstract. The coal bottom ash is a solid waste generated from coal-fired thermal power plants that contains high alumino-silicates resources. Rice husk ash was burned from rice husk which has over 80% silica in its chemical composition.

Rice Husk Technology Liquid Sodium Silicate and Activated Carbon Production Rice husk ash is first digested with caustic soda and than filtered. In the filter diluted liquid sodium silicate is separated from unwashed carbon filter cake. The diluted liquid sodium silicate is fed to storage tanks while the carbon cake in the filter is washed and chemically cleaned before dried in the drying sec

Kongkachuichay, “Phase Diagram of Zeolites Synthesized from Perlite and Rice Husk Ash,” 9th APCChE Congress, 29 September-3 October 2002, Christchurch, NZ, Paper # 731) and organic acid solutions before burning, the second with boiling water, both using an autoclave at

CHEM PLANT & ENGINEERING SERVICES – Exporter, Manufacturer & Supplier of Sodium Silicate Plant From Rice Husk Ash based in Kolkata, India

www.theinternationaljournal.org > RJSITM: Volume: 03, Number: 02, December-2013 Page 47 Magnetite particle synthesis using electrolytes sodium silicate from rice husk ash base material be

CHEMISTRY & CHEMICAL TECHNOLOGY Vol. 3, No. 4, 2009 Chemical Technology Abstract. Rice husk ash was used to produce sodium silicate with SiO 2 /Na

Synthesizing one-part geopolymers from rice husk ash

RICE HUSK ASH SILICA AS A SUPPORT MATERIAL FOR

K.Bogeshwaran et al /Int.J. ChemTech Res.2014,6(9),pp 4337-4345. 4339 Ca K Mg Rice Husk SiO 2 500-700 0C Na Al Cl Stage 2: Preparation of Sodium Silicate from Rice Husk Ash

Kongkachuichay, “Phase Diagram of Zeolites Synthesized from Perlite and Rice Husk Ash,” 9th APCChE Congress, 29 September-3 October 2002, Christchurch, NZ, Paper # 731) and organic acid solutions before burning, the second with boiling water, both using an autoclave at

The conventional process and other process using sodium silicate obtained from rice husk ash involves acid (i.e., sulphuric acid) precipitation of the sodium silicate to produce Precipitated Silica. Sodium sulphate is a waste that is generated and this liquid effluent requires elaborate treatment to meet emission standards. 3. The process requires effluent treatment plant for treating sodium

Rice husk ash, an agricultural waste material obtained from rice mills. It is a low- It is a low- density material that causes disposal problems but is rich in amorphous chemically

Rice husk large ash content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash, which has wide market and Nanosilicate Extraction from Rice Husk Ash as Green Corrosion

The ash generates was used in the production of sodium silicate. Optimum time for producing rice husk ash at 650 0 C is 4 hours. It is possible to dissolve great part of contained silica in leached ashes by the reaction with aqueous solution of NaOH at 80 0 C temperature.

synthesized from sodium silicate derived from rice husk ash using NaOH with different concentration (1.0, 1.67; 3.33; 5.0, 6.67 M) and sodium aluminate by sol-gel method followed by hydrothermal process at 100 °C for 5 hours.

rice husk ash with potassium or sodium based alkaline solutions. Geopolymers possess three dimensional alumino silicate Geopolymers possess three dimensional alumino silicate networks and is being used as a substitute to Portland cement concrete due to its excellent mechanical properties.

Rice husk ash thermal insulators were formulated using rice husk ash as the major raw material, starch, sodium silicate and Bentonite as binders and plasticizer and water. The components were mixed manually for 15 minutes.

(sodium silicate) (water) 180-200oC Silica is digested from ash using caustic soda as sodium silicate. The temperature is in the range of 90-100oC and pressure is the normal atmospheric pressure. But high reaction temperature and pressure can be avoided if ash obtained by burning rice husk at 650oC is used. 1 atm (silica) (sodium (water) sulphate) The addition of sulphuric acid is done very

XRDof Synthetic Zeolite for Surfactant Builder

Rice husk ash as a source of silica in alkali-activated

Sodium silicate is the generic name for a series of compounds derived from soluble sodium silicate glasses. They are water solutions of sodium oxide and silicon dioxide combined in various ratios. These are sold as 20% to 50% aqueous solutions called water glass. Rice husk is an alternative source for silica. Rice husk a major by-product of the rice milling industry, is one of the most

Widely considered a carbon neutral product, rice husk ash is an environmentally friendly resource for producing silica nanomaterials and synthetic zeolite. The proprietary production process used in this technology involves incinerating rice husks to produce silica and will be further treated with alumina and sodium silicate to synthesise the final product, which can be used in petrochemical

In this work sodium silicate was produced by reacting rice hull ash (RHA) and aqueous sodium hydroxide, in open and closed reaction systems. The studied process variables were time, temperature of reaction and composition of the reaction mixture (expressed in terms of …

The different types of biomass used for gasification, rice husk has a high ash content varying from 18-20%. The demand of sodium silicate is increasing day …

Index Terms—Rice husk ash, silica aerogel microparticles, supercritical carbon dioxide, water-in-oil emulsion. I. and sodium silicate solution (water glass). These raw materials are more expensive and also carcinogenic. Therefore, for large-scale

Performance of sodium silicate free geopolymers from

Sodium Silicate from Rice Husk Ash Entrepreneur India

Abstract. The coal bottom ash is a solid waste generated from coal-fired thermal power plants that contains high alumino-silicates resources. Rice husk ash was burned from rice husk which has over 80% silica in its chemical composition.

The different types of biomass used for gasification, rice husk has a high ash content varying from 18-20%. The demand of sodium silicate is increasing day …

utilizing sodium silicate, derived from rice husk ash. Gel powder was calcined at 700 °C Gel powder was calcined at 700 °C for 2 h to get a reactive glass-ceramic powder.

Sodium silicate solution was obtained using Rice Husk Ash in a hydrothermal process. Obtained sodium silicate was used for activating binders with fly ash and slag. Compressive strength of mortar and microstructure of paste were investigated.

Rice Husk Technology Liquid Sodium Silicate and Activated Carbon Production Rice husk ash is first digested with caustic soda and than filtered. In the filter diluted liquid sodium silicate is separated from unwashed carbon filter cake. The diluted liquid sodium silicate is fed to storage tanks while the carbon cake in the filter is washed and chemically cleaned before dried in the drying sec

The employed rice husks from Tanzania were calcined at 650 C for 90 min to yield the rice husk ash (RHA) and the ash then allowed to cool down naturally to room temperature.

Kamath and Proctor [17] reported that the rice husk could be dissolved in sodium hydroxide solution, and then titrated with acid to obtain silica gel.

Extraction of Silica from Rice Husk 73 B. Process Description The initial step is extraction of silica from ash as sodium silicate using caustic soda.

Rice husk ash thermal insulators were formulated using rice husk ash as the major raw material, starch, sodium silicate and Bentonite as binders and plasticizer and water. The components were mixed manually for 15 minutes.

Introduction: Introduction India produces around 25 million tons of rice husk (widely available waste) 78% of weight as rice, broken rice and bran, rest 22% of weight of paddy as husk. 75% of organic volatile matter and 25% of weight is converted as rice husk ash (RHA) during firing process.

A schematic flow chart for preparation of silica gel particles from rice husk ash is proposed as shown in Figure 1 rice husk ash was mixed with 250 ml of 1 N sodium hydroxide aqueous solution. The mixture was refluxed for 3 h at 110°C.

extraction of silica from rice husk GAURAV SONI

DOCTOR OF PHILOSOPHY ethesis

RICE HUSK ASH SILICA AS A SUPPORT MATERIAL FOR

CHEM PLANT & ENGINEERING SERVICES – Exporter, Manufacturer & Supplier of Sodium Silicate Plant From Rice Husk Ash based in Kolkata, India

Sodium Silicate Plant From Rice Husk Ash Sodium Silicate

10 Seun Samuel Owoeye and Olanireti Esther Isinkaye: Effects of Extraction Temperature and Time on the Physical Properties of Soluble Sodium Silicate from Rice Husk Ash

SODIUM SILICATE FROM RICE HUSK entrepreneurindia.co

In this research, sodium silicate (Na 2 SiO 3) was prepared by rice husk ash reacted with 10 M sodium hydroxide. The mixtures were heated by microwave at …

Preparation of Silica Powder from Rice Husk

Performance of sodium silicate free geopolymers from

Rice husk ash was prepared and washed with acid to remove the mineral impurities. Further, it was treated with sodium hydroxide to form sodium silicate solution. The silicate solution formed was titrated with hydrochloric acid and precipitation (in the form of gel) formation takes place below pH 10. Keywords: Rice husk, Rice husk ash, Silica xerogels, Minerals, Sodium silicate, Sodium

SODIUM SILICATE FROM RICE HUSK entrepreneurindia.co

Preparation and Characterization of Silica Material from

Utilization of Red Mud and Rice Husk Ash for Synthesizing

Sodium silicate solution was obtained using Rice Husk Ash in a hydrothermal process. Obtained sodium silicate was used for activating binders with fly ash and slag. Compressive strength of mortar and microstructure of paste were investigated.

15th European Biomass Conference & Exhibition 7-11 May

Properties of Geopolymers Made from Fired Clay Bricks

sodium silicate films, and so on. 2.7 SUMMARY Paddy rice production in India is as close as 150 million tones per annum. Of all the plant residues, the ash of rice husk contains the highest proportion of silica. Rice husk ash, obtained from the incineration of husk, is rich in silica (87 – 97 percent) with . 10 small amounts of alkalis and other trace elements. Silica in RHA exists in

Preparation and characterization of amorphous silica and

Use of Sodium Silicate from Rice Husk Ash Basic Materials

Extraction of Silica from Rice Husk 73 B. Process Description The initial step is extraction of silica from ash as sodium silicate using caustic soda.

RICE HUSK ASH REFRACTORY THE TEMPERATURE DEPENDENT

Sodium silicate is produc ed by reacting rice hull ash (RHA) with aqueous NaOH and silic a is precipitated from the sodium silic ate by acidificati on. In the pres ent work, conversi on of about

Preparation and characterization of amorphous silica and

Learn how a rice miller can earn extra income. Silica

Sodium Silicate from Rice Husk Ash Niir Project Consultancy Services (NPCS) through its network of project consultants in a wide range of business and technological disciplines is engaged in providing services to its clients by way of preparation of project reports.

RICE HUSK ASH REFRACTORY THE TEMPERATURE DEPENDENT

Preparation of Silica Gel from Rice Husk Ash Using

MILLTEC Silica from Rice Husk Ash (RHA), Along with silica, we can also extract byproducts like activated carbon and sodium carbonate from RHA. For more information on Silica from Rice Husk Ash , contact us @ TOLL-FREE: 1800-102-8431

RICE HUSK ASH SILICA AS A SUPPORT MATERIAL FOR

A Simple Process to Prepare Silica Aerogel Microparticles

Use of Sodium Silicate from Rice Husk Ash Basic Materials

Characterization of Silica Produced from Rice Husk Ash: Comparison of Purification and Processing Methods 513 Table 1. Studies that investigated methods used to obtain and purify silica from rice husk ash.

Conversion of rice hull ash into soluble sodium silicate

Synthesizing one-part geopolymers from rice husk ash

(PDF) Conversion of rice hull ash into soluble sodium silicate

http://www.theinternationaljournal.org > RJSITM: Volume: 03, Number: 02, December-2013 Page 47 Magnetite particle synthesis using electrolytes sodium silicate from rice husk ash base material be

15th European Biomass Conference & Exhibition 7-11 May

PROJECT DISCRIPTION RICE HUSK AMORPHOS SILICA AS

Effect of Temperature towards Rice Husk Silica

ABSTRACT. This study assessed the mechanical properties, and structural changes induced by high temperature exposure, of alkali-silicate activated slag cements produced with sodium silicates derived from silica fume (SF) and rice husk ash (RHA).

silicon extract machinery from rice husk plasmar.com.au

Preparation of Silica Gel from Rice Husk Ash Using

Preparation of Silica by Alkaline-Heating and

utilizing sodium silicate, derived from rice husk ash. Gel powder was calcined at 700 °C Gel powder was calcined at 700 °C for 2 h to get a reactive glass-ceramic powder.

Synthesizing one-part geopolymers from rice husk ash

Rice Husk Ash Silicon Dioxide Sodium Hydroxide

Performance of sodium silicate free geopolymers from

Rice husk ash thermal insulators were formulated using rice husk ash as the major raw material, starch, sodium silicate and Bentonite as binders and plasticizer and water. The components were mixed manually for 15 minutes.

Chemical Engineering & Process Technology

Rice Husk Ash Silicon Dioxide Sodium Hydroxide

Synthesizing one-part geopolymers from rice husk ash

sodium silicate films, and so on. 2.7 SUMMARY Paddy rice production in India is as close as 150 million tones per annum. Of all the plant residues, the ash of rice husk contains the highest proportion of silica. Rice husk ash, obtained from the incineration of husk, is rich in silica (87 – 97 percent) with . 10 small amounts of alkalis and other trace elements. Silica in RHA exists in

SILICA SOL OBTAINED FROM RICE HUSK ASH

SODIUM SILICATE FROM RICE HUSK entrepreneurindia.co

Hydroxide attack is useful in the conversion of rice hull ash from thermoelectric plants into sodium silicate. The same hull treatment was performed on ash (12 wt% of carbon and 88 inorganic matter) with a SiO2/Na2O ratio of 2.0 and 1.2. 57 wt% of the ash was dissolved in the first case and 67 wt% in the second. After filtering, the silicate solutions were clear, as was the precipitated silica

Preparation and characterization of amorphous silica and

(sodium silicate) (water) 180-200oC Silica is digested from ash using caustic soda as sodium silicate. The temperature is in the range of 90-100oC and pressure is the normal atmospheric pressure. But high reaction temperature and pressure can be avoided if ash obtained by burning rice husk at 650oC is used. 1 atm (silica)+ (sodium +(water) sulphate) The addition of sulphuric acid is done very

extraction of silica from rice husk GAURAV SONI

Precipitated Silica And Activated Carbon from Rice Husk

A schematic flow chart for preparation of silica gel particles from rice husk ash is proposed as shown in Figure 1 rice husk ash was mixed with 250 ml of 1 N sodium hydroxide aqueous solution. The mixture was refluxed for 3 h at 110°C.

A Simple Process to Prepare Silica Aerogel Microparticles

Use of Vietnamese rice husk ash for the production of

yield of 96.7% was obtained for rice husk derived sodium silicate catalyst, whereas for rice husk derived lithium silicate catalyst, the biodiesel yield of 99.4% was obtained at optimum condition of 4wt% catalyst concentration, reaction temperature of 65 o C, reaction time of

Preparation of Silica Gel from Rice Husk Ash Using

How to Make Nano Silica From Extracted Silica Rice Husk

In this research, sodium silicate (Na 2 SiO 3) was prepared by rice husk ash reacted with 10 M sodium hydroxide. The mixtures were heated by microwave at …

sodium-silicate Manufacturing Project Information

Properties of Geopolymers Made from Fired Clay Bricks

The Manufacture of a Cement Extender from Rice-Husks using

replace commercial silica commonly used in natural rubber industries with rice husk ash silica (RHAS). Silica was extracted Silica was extracted from RHA by using alkaline extraction followed by …

Preparation and Characterization of Silica Material from

utilizing sodium silicate, derived from rice husk ash. Gel powder was calcined at 700 °C Gel powder was calcined at 700 °C for 2 h to get a reactive glass-ceramic powder.

Use of Sodium Silicate from Rice Husk Ash Basic Materials

Production of Sodium Silicate Using Rice Husk Ash

Sodium Silicate from Rice Husk Ash Niir Project Consultancy Services (NPCS) through its network of project consultants in a wide range of business and technological disciplines is engaged in providing services to its clients by way of preparation of project reports.

Sodium Silicate Plant From Rice Husk Ash in Kolkata West

Production of Silica from Rice husk sphinxsai.com

Use of Sodium Silicate from Rice Husk Ash Basic Materials

10 Seun Samuel Owoeye and Olanireti Esther Isinkaye: Effects of Extraction Temperature and Time on the Physical Properties of Soluble Sodium Silicate from Rice Husk Ash

PROJECT DISCRIPTION RICE HUSK AMORPHOS SILICA AS

Synthesis of ZSM-5 zeolite from lignite fly ash and rice

DOCTOR OF PHILOSOPHY ethesis

Established in 1997, CHEM PLANT & ENGINEERING SERVICES has been a leading name in offering top notch Cattle Feed Supplements. Located in Kolkata, West Bengal, we offer the best quality Sodium Silicate Plant From Rice Husk Ash to our customers at best prices in the industry.

SILICA SOL OBTAINED FROM RICE HUSK ASH

produce sodium silicate solution and precipitated silica was produced by the neutralization of sodium silicate solution. Rice Husks soaked in nitric acid produced the maximum amount of the sodium silicate solution and precipitated silica. Sodium oxide (Na 2O) content and silica (SiO 2) content in the sodium silicate solution were also determined. Extracted precipitated silica particles were

Preparation of Silica by Alkaline-Heating and

Sodium silicate is the generic name for a series of compounds derived from soluble sodium silicate glasses. They are water solutions of sodium oxide and silicon dioxide combined in various ratios. These are sold as 20% to 50% aqueous solutions called water glass. Rice husk is an alternative source for silica. Rice husk a major by-product of the rice milling industry, is one of the most

Preparation and characterization of amorphous silica and

How to Make Nano Silica From Extracted Silica Rice Husk

SILICA SOL OBTAINED FROM RICE HUSK ASH

produce sodium silicate solution and precipitated silica was produced by the neutralization of sodium silicate solution. Rice Husks soaked in nitric acid produced the maximum amount of the sodium silicate solution and precipitated silica. Sodium oxide (Na 2O) content and silica (SiO 2) content in the sodium silicate solution were also determined. Extracted precipitated silica particles were

silicon extract machinery from rice husk plasmar.com.au

Extraction of Silica from Rice Husk IJERD

Preparation and Characterization of Silica Material from

Sodium silicate is the generic name for a series of compounds derived from soluble sodium silicate glasses. They are water solutions of sodium oxide and silicon dioxide combined in various ratios. These are sold as 20% to 50% aqueous solutions called water glass. Rice husk is an alternative source for silica. Rice husk a major by-product of the rice milling industry, is one of the most

Rice husk ash as a source of silica in alkali-activated

How to Make Nano Silica From Extracted Silica Rice Husk

rice husk Navin Chouragade Academia.edu

A Simple Method for Production of Humidity Indicating Silica Gel from Rice Husk Ash Sodium silicate can be produced very cheaply from the RHA by simply boiling it with refluxed sodium hydroxide solution for 1 hour whereas this sodium silicate, the precursor for silica production, is currently manufactured by melting quartz sand with sodium carbonate at 1300°C.(8) Silica gel has been used

Utilization of Red Mud and Rice Husk Ash for Synthesizing

A Simple Process to Prepare Silica Aerogel Microparticles

Rice husk large ash content and sodium silicate content in the ash it becomes economical to extract silica from the rice husk ash, which has wide market and also takes care of ash disposal. Rice husk …

Preparation and Characterization of Silica Material from

Sodium silicate is the generic name for a series of compounds derived from soluble sodium silicate glasses. They are water solutions of sodium oxide and silicon dioxide combined in various ratios. These are sold as 20% to 50% aqueous solutions called water glass. Rice husk is an alternative source for silica. Rice husk a major by-product of the rice milling industry, is one of the most

Sodium Silicate from Rice Husk Ash Entrepreneur India

Preparation of Silica by Alkaline-Heating and

Development of Geopolymer-Based Materials from Coal Bottom