Soda ash manufacturing process pdf

Soda Ash Dense (commonly known as sodium carbonate) is a white powder designed for use in powdered detergents and cleaners, chemical processes, …

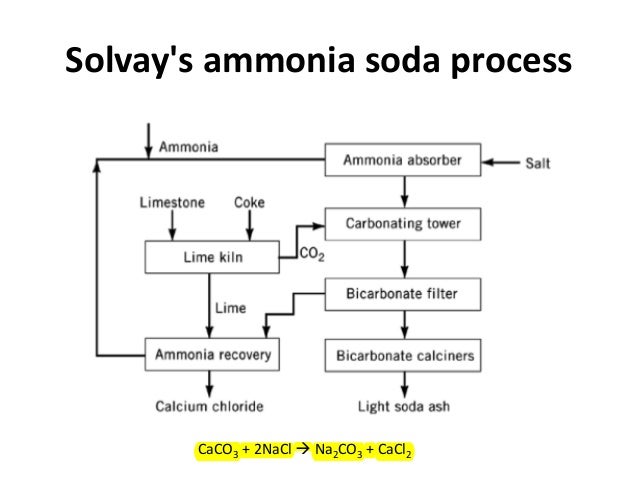

The Solvay process is used to produce Soda Ash, which nowadays is extensively used in the most companies all over the world. In this method, salt and limestone are used as the main raw materials and common for producing Soda Ash.

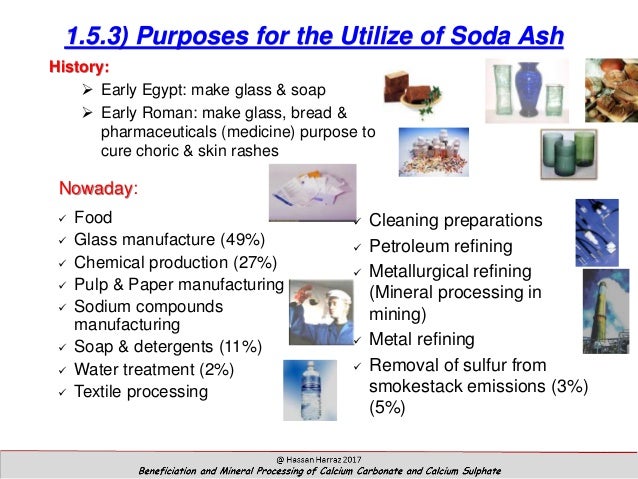

soda ash for flat glass industry is the highest at 25%, followed by demand for container glass at 19%. The other sources of demand however, include soap / detergents, chemicals, and metals/mining, pulp and paper, and others. The 2013 world Soda Ash demand by region was led by Northeast Asia (mainly China) at 45%. Other import regions for Soda Ash demand included Europe, split into West Europe

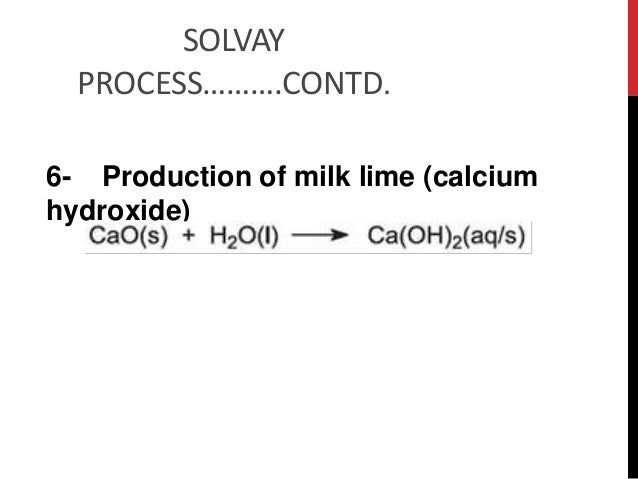

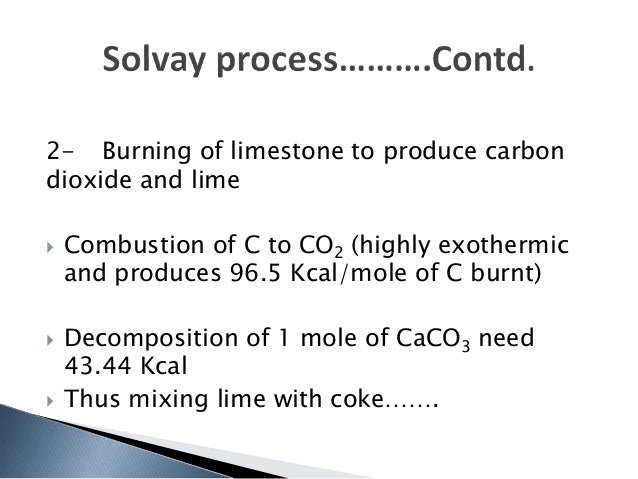

To counter this effect , lower part of Solvay tower is cooled , ppt of NaHCO 3 are separated by vacuum filtration and washed to remove ammonium salts. Conversion of NaHCO 3 to Na 2 CO 3 Dry sodium bicarbonate is heated in rotary furnace called ” CALCINER ” to give anhydrous sodium carbonate or soda ash.

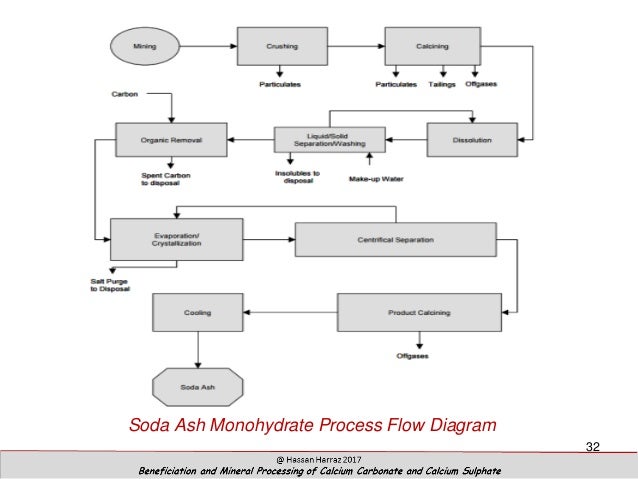

flow sheet diagram of crushing, Process Flow Diagram Of Jaggery Manufacturing Plant. sugar factory process flow chart wikipedia BINQ Mining . 2013 · Flow diagram of the soda ash plant. soda ash manufacturing process flow diagram – Crusher.

This is known as the Solvay process and was the main source of soda ash until the Wyoming trona deposits were discovered. However, it is more expensive than mining natural sodium carbonate deposits. However, it is more expensive than mining natural sodium carbonate deposits.

Soda Ash Manufacturing Download as PDF, TXT or read online from Scribd

Particulate emissions from soda ash manufacturing facilities in Wyoming are regulated in terms of total filterable and condensible particulate matter, with no regard to particle size; thus, available test data do not afford a particle size distribution.

Soda ash is a key chemical for producing soap, paper making, baking soda production, and bleaching fabrics and paper. Origin of soda ash term The name “soda ash” is based on the principal historical method of obtaining alkali, which was by using water to extract it from ashes.

rock crushing machine design pdf ore process crushing . gt mining solutions gt rock crushing machine design pdf mining .por le gold crusher. More Details . Read More; simons cone crusher rebuild specs amroninternational. a crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.the earliest crushers were hand held stones, where the weight of the stone

Sodium Carbonate or Soda Ash-Na2CO3 Sodium Bicarbonate-NaHCO3 Sodium Sesquicarbonate, or Modified Soda Potassium Carbonate Oxygen-releasing Compounds Sundry Inorganic Builders Borax Sodium Chloride Magnesium Sulphate. www.entrepreneurindia.co Insoluble Inorganic Fillers Caustic Alkalis Ammonia Colloidal Silica Sodium Hypochlorite 3. Recent Developments in Surfactant …

En.wikipedia.org The Solvay process or ammonia-soda process is the major industrial process for the production of sodium carbonate (soda ash, Na 2 CO 3). The ammonia-soda process was developed into its modern form by Ernest Solvay during the 1860s.

the ammonium chloride and soda ash dual manufacturing process in japan Download the ammonium chloride and soda ash dual manufacturing process in japan or read online books in PDF, EPUB, Tuebl, and Mobi Format.

Soda ash manufacturing process” Keyword Found Websites

Process Flow Diagram Of Washing Soda spitsid.eu

20/12/2018 · Soda ash is the common name for sodium carbonate, a chemical compound frequently used in manufacturing, industry, and even around the house. Glass production is one of the primary uses for sodium carbonate.

Manufacturing sodium carbonate by the Solvay process: page 3 of 4 RSaC Light sodium carbonate (light ash) This is made by taking the filtered sodium hydrogencarbonate and heating it.

In the eighteenth century soda ash was produced by LeBlanc process based on roasting salt cake with carbon and limestone. The synthetic process for the manufacture of soda ash by ammonia soda process

6 Manufacturing Process 13 7 Flow Chart 16 8 Effluent Treatment Process 17 9 Flow Chart 17 Ferrous Ascorbate 10 Manufacturing Process 18 11 Flow Chart 22 12 Effluent Treatment Process 23 13 Flow Chart 24 Paracetamol – Granules 14 Manufacturing Process 25 15 Flow Chart 28 . Adroit Pharmaceuticals Pvt.Ltd. Manufacturing & Effluent Treatment Process Vil-Fetri, Nagpur. _____ …

Solvay Process make Sodium carbonate in chemical . The Solvay Process (also known as the ammonia-soda process), developed in 1861, is the world’s major industrial process for the production of sodium carbonate (NaCO 3), or soda ash.

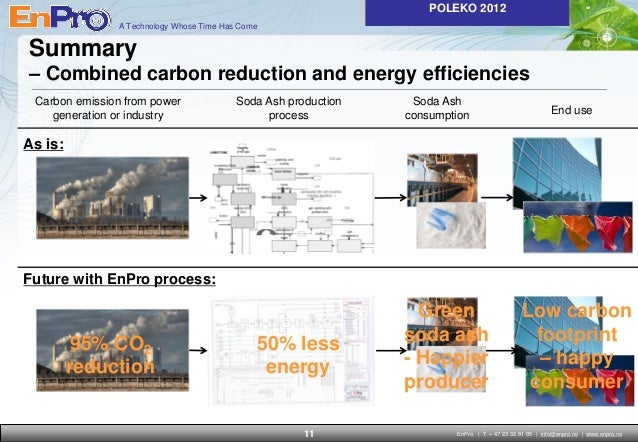

In this study, we quantified the industrial process emissions from the production of alumina, plate glass, soda ash, ammonia and calcium carbide. The total emissions from the industrial processing of these five products reached 233 Mt CO 2 in 2013.

Sodium Silicate Manufacturing Sand Soda Ash Fuel Furnace 24000F 50% Caustic Soda Water / Steam Dissolver Adjust Ratio And Solids Liquid Silicate Storage Dryer Granular Meta Silicates. 4 General Applications This list includes both major and minor uses for silicates. The uses noted illus-trate the wide range of applications for sodium silicates. Abrasive Wheels Absorbents Adhesives …

Process for manufacturing a soda ash peroxygen Download PDF Info Publication number EP0364840B2. process hydrogen peroxide Prior art date 1988-10-06 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired – Lifetime Application number …

Penrice forms joint venture to resell and distribute soda ash The Osborne plant will continue to operate as, a sodium bicarbonate manufacturing facility and a quicklime manufacturing facility. Key features of the JV include: o. The JV will be owned by SASS as to 67% and Penrice as to 33% . o. The term of the JV will be a minimum of 6 years . o. SASS will provide a loan to Penrice of

Soda ash Soda crystal Washing soda . Product Overview . Solvay Chemicals, Inc. does not sell sodium carbonate directly to consumers. Consumers may be exposed to sodium carbonate in many consumer product applications where the sodium carbonate is not transformed or reacted and is present in powder or granule form. Sodium carbonate is a white, granular or powdered solid. It is used …

Soda-lime glass consists of sand, limestone, soda ash, and cullet (broken glass). The manufacture of such glass is in four phases: (1) preparation of raw material, (2) melting in a furnace, (3) forming and (4) finishing. Figure 11.15-1 is a diagram for typical glass manufacturing. The products of this industry are flat glass, container glass, and pressed and blown glass. The procedures for

However, a soda ash manufacturing facility should report its annual trona consumption, number of soda ash manufacturing lines, fractional purity of trona consumed or soda ash produced, annual soda ash manufacturing, annual soda ash production capacity, electricity usage (kilowatt- …

Soda Ash Manufacturing Industry. Production of Sodium Carbonate / Soda Crystals/ Soda Ash / Washing Soda. Exploring Business Opportunity in Soda Ash Production Soda ash, also know

slight increase in the soda, the less viscous the glass becomes and the more time in seconds the forming process has to form the bottle before the glass stiffens.

National carbon emissions from the industry process: Production of glass, soda ash, ammonia, calcium carbide and alumina Zhu Liu⇑ Resnick Sustainability Institute, California Institute of Technology, Pasadena, CA 91125, USA

11.15 Glass Manufacturing epa.gov

Through innovative process development and results-oriented pilot testing, Veolia Water Technologies helped American Soda reach their goal to produce exceptional high-quality soda ash and high-purity sodium bicarbonate from natural nacholite deposits. An HPD® sodium carbonate monohydrate crystallization system and a unique HPD sodium bicarbonate crystallization system were the first of

A soda ash manufacturing facility is any facility that produces soda ash by calcining trona, calcining sodium sesquicarbonate, or by using a liquid alkaline feedstock process that directly produces carbon

The Manufacturing Process The manufacture of sodium hypochlorite bleach requires several steps. All the steps can be carried out at one large manufacturing facility, or the chlorine and caustic soda can be shipped from different plants to the reactor site. Both chlorine and caustic soda are hazardous chemicals and are transported according to strict regulations. Preparing the components 1

soda ash manufacturing process flow diagram by solvay use of ammonia still in solvay process flow diagram The conveyancing process explained in a simple flow Chat Online Draw The Flow Sheet Iron Ore Wet Processing Plant Showing Steps From process flow diagram by solvay is a basic diagram on Iron Ore flow sheet Chat Online soda ash – ash ish hypertension guidelines 2014 ppt Production of Soda Ash and downstream products (beneficiation of limestone) Project Concept ` completed The establishment of a synthetic Soda Ash manufacturing plant in southern KwaZulu-Natal (Hibiscus Municipality) ` Soda Ash products are currently being imported into South Africa. Soda Ash (sodium carbonate) plays a significant role as a strategic feed material for the manufacture of

The Solvay process or ammonia-soda process is the major industrial process for the production of sodium carbonate (soda ash, Na 2 CO 3). The ammonia-soda process was developed into its modern form by Ernest Solvay during the 1860s.

The aim of the project was to study the manufacturing of synthetic soda ash (sodium carbonate, Na2CO3) on an industrial scale. Currently all Soda ash that is used in South Africa for manufacturing glass is imported at a high cost, and the company Nampak Wiegand Glass (South Africa) is investigating the possibility to locally manufacture

Soda ash, the trade name for sodium carbonate (Na 2 CO 3), is a white, anhydrous, powdered or granular material. It is an essential raw material used in the manufacturing of glass, detergents chemicals and other industrial products.

This paper is concerned with the technical and economic aspects of the soda ash production in the Arabian Gulf. Five different manufacturing methods are outlined.

chlor-alkali process needs huge amounts of electricity and electrical energy is a major input. The main pollutant outputs which are common to all three electrolytic processes are chlorine gas emissions to air, free oxidants to water, spent acids, cooling agents, and impurities removed

dense soda ash process flow diagram – cleanroominstruments.in. Soda ash production process flow diagram Production process and methods for A process for the production of dense soda ash the process comprising mechanically . get more info.

Soda ash is a key chemical for producing soap, paper making, baking soda production, and bleaching fabrics and paper. Origin of soda ash term The name “soda ash” is based on the principal historical method of obtaining alkali, which was by using water to extract it from ashes. The word “soda” (from the Middle Latin) originally referred to certain plants that grow in salt marshes; it was

16/04/2013 · The Solvay process or ammonia-soda process is the major industrial process for … The worldwide production of soda ash in 2005 has been estimated at 42 billion …. carbon dioxide bubbled up through a descending flow of brine, together with …

The electrolysis process produces 2.25 tonnes of 50% caustic soda with each tonne of chlorine. The primary raw material is common salt, usually in the form of underground deposits which are brought to the surface as a solution in a pumped high pressure water supply.

for the soda ash production process, quantifying the amount of limestone available in the silo is essential for assuring continuous production. The APM 3DLevelScanner’s unique surface mapping technology supports this by delivering real-time volume measurements of the stored material and by generating a 3D image of the stored content allowing early detection of build- ups. This is the basis

Manufacturing of sodium carbonate using solvay process

Soda Ash Manufacturing VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH (1) Le Blanc Process This process was invented by Nicolas Le Blanc, a French man ,who in 1775, among several others submitted an outline of a process for making soda ash from common salt, in response to an offer of reward by the French academy in paris.

Foreword for Volume I Soda ash is an important global commodity with a strong possibility of increasing demand. For this reason, utilization of world sodium carbonate resources into the

Soda ash, also known as sodium carbonate (Na2CO3), is an alkali chemical refined from the mineral trona or naturally occurring sodium carbonate-bearing brines (both referred to as natural soda ash), the mineral nahcolite (referred to as natural sodium bicarbonate, from which soda ash can be produced), or manufactured from one of several chemical processes (referred to as synthetic soda ash).

3 The Soda Ash is the basic inorganic raw material for manufacturing essential components of daily life. It is used in manufacture of :- float glasses, fiber glass, glass for Industrial use.

One obvious reason for establishing caustic soda manufacturing operations in such close proximity to these larger plant complexes is the ready availability of the soda ash. Another is that the second reactant utilized in the causticization process; i.e., the lime, also is readily available from such soda ash manufacturing complexes as a co-product.

The process of obtaining soda ash is, in short, the secretion of a solution composed of water, sodium chloride, ammonia and carbon dioxide sparingly soluble salt of sodium bicarbonate (NaHCO 3 ), but remains in solution of ammonium chloride (NH 4 Cl).

Figure 2 Process block diagram for the manufacture of soda ash by the Solvay process Soda Ash Process BREF – Issue N° 3 – March 2004 23 The usual names of the plant area where the main process operations are taking place are given in Table 4.

Abstract— Soda ash or sodium carbonate is by nature a weak base and hence lower in alkalinity. The agro based pulp and paper mill with unconventional chemical recovery process end up with production of soda ash or sodium carbonate. The soda ash thus produced is of low quality and sold to soap manufacturing units. The pulping and bleaching process requires at some stage low alkalinity where

project: expansion of soda ash, cement and captive cogeneration power plant applicant: m/s. tata chemicals ltd. pre-feasibility report iii index s.no. content page no. 1 executive summary 1 2 introduction of the project/ background information 3-5 2.1 identification of project and project proponent 3 2.2 brief information about the project 3 2.3 need for the project and its importance to the

25/05/2015 · MAKING OF SODIUM CARBONATE BY SOLVARY PROCESS. Sodium carbonate is known as washing soda or soda ash. It is commonly occurred as a crystalline heptahydrate which readily effloresces to form a white powder, the monohydrate.

soda ash manufacturing process flow diagram BINQ Mining

RESEARCH ARTICLE 5 Utilization of Soda Ash in Pulping and

manufacturing process of soda ash. The mathematical model and the simulation The mathematical model and the simulation results proved to be a reliable tool for analyzing and optimizing the real plant

limestone in a process known as the Solvay process. Soda ash is the most important high tonnage, low cost, reasonably pure, soluble alkali available to the industries as well to the laboratory.

Soda ash, owing to its ability to control the furnace temperature necessary to melt silica makes it an essential element in glass manufacturing process. This application segment is expected to generate over 35 million tons by 2024 and is supposed to account for just under 50% of the entire demand.

The Solvay Process (also known as the ammonia-soda process), developed in 1861, is the world’s major industrial process for the production of sodium carbonate (NaCO3), or soda ash. Solvay

Glass production involves two main methods – the float glass process that produces sheet glass, and glassblowing that produces bottles and other containers. Contents 1 Glass container production

25/08/2018 · FMC Soda Ash Plant, Wyoming Chemical Technology. Soda ash can be mined as a hydrated ore and then processed into the required . The choice of either process depends upon the economics of mining as.

The Sodium Bicarbonate produced via this process is then converted to the commercially important chemical Sodium Carbonate; also known as Soda Ash (Na 2 CO 3) or Washing Soda (Na 2 CO 3•10H 2 O). 2 NaHCO 3 (s) Na 2 CO 3 (s) + CO 2 (g) + H 2 O(g) By 1890, most of the Soda Ash produced worldwide was produced as a result of the Solvay Process. Currently, three-quarters of the worldwide

Sodium Carbonate (Soda Ash) solvay.us

Soda Ash Production apm-solutions.com

Technical Support Document for the Soda Ash Manufacturing. Technical Support Document for the Soda Ash Manufacturing Sector: Proposed Rule for Mandatory Reporting of Greenhouse Gases Office. LIVE CHAT GET PRICE. PDF Natural Soda Ash Occurrences Process And Use . Browse and Read Natural Soda Ash Occurrences Process And Use. Title Type data processing and reconciliation for chemical process

The silica and soda ash are melted in a furnace at temperatures of 17000C – this is called the batch. Limestone is added to give glass its hard, smooth texture. The batch turns into a hot, thick liquid known as molten glass. Glass Recycling. Glass recycling tips Remove all lids or caps Rinse out bottles and jars www.logan.qld.gov.au a load to be rejected and sent to the landfill. The glass

A soda ash manufacturing facility is any facility that produces soda ash by calcining trona, calcining sodium sesquicarbonate, or by using a liquid alkaline feedstock process that directly produces carbon dioxide (CO. 2). In the context of the soda ash manufacturing sector, “calcining” means the thermal/chemical conversion

Interesting facts about Soda ash / Washing soda / Sodium

25/12/2018 · Soda ash, also known as sodium carbonate (Na2CO3), is an alkali chemical refined from the mineral trona or naturally occurring sodium carbonate-bearing brines (both referred to as natural soda ash

soda ash manufacturing process flow diagram by solvay process VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH several others submitted an outline of a process for making soda ash from impurities ,is sprayed from the

soda ash manufacturing tikkeltjezeeuws.nl

SURFACTANTS & DETERGENT ADDITIVES Soda Ash Dense

– Soda ash Production Sodium Carbonate Sodium Hydroxide

National carbon emissions from the industry process

soda ash manufacturing process flow diagram vics2017.org

Technical Support Document for the Soda Ash Manufacturing

Tata Chemicals Mithapur ibm.gov.in

Sodium Carbonate (Soda Ash) solvay.us

Abstract— Soda ash or sodium carbonate is by nature a weak base and hence lower in alkalinity. The agro based pulp and paper mill with unconventional chemical recovery process end up with production of soda ash or sodium carbonate. The soda ash thus produced is of low quality and sold to soap manufacturing units. The pulping and bleaching process requires at some stage low alkalinity where

The Solvay process is used to produce Soda Ash, which nowadays is extensively used in the most companies all over the world. In this method, salt and limestone are used as the main raw materials and common for producing Soda Ash.

soda ash for flat glass industry is the highest at 25%, followed by demand for container glass at 19%. The other sources of demand however, include soap / detergents, chemicals, and metals/mining, pulp and paper, and others. The 2013 world Soda Ash demand by region was led by Northeast Asia (mainly China) at 45%. Other import regions for Soda Ash demand included Europe, split into West Europe

The Sodium Bicarbonate produced via this process is then converted to the commercially important chemical Sodium Carbonate; also known as Soda Ash (Na 2 CO 3) or Washing Soda (Na 2 CO 3•10H 2 O). 2 NaHCO 3 (s) Na 2 CO 3 (s) CO 2 (g) H 2 O(g) By 1890, most of the Soda Ash produced worldwide was produced as a result of the Solvay Process. Currently, three-quarters of the worldwide

Soda Ash Manufacturing VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH (1) Le Blanc Process This process was invented by Nicolas Le Blanc, a French man ,who in 1775, among several others submitted an outline of a process for making soda ash from common salt, in response to an offer of reward by the French academy in paris.

Penrice forms joint venture to resell and distribute soda ash The Osborne plant will continue to operate as, a sodium bicarbonate manufacturing facility and a quicklime manufacturing facility. Key features of the JV include: o. The JV will be owned by SASS as to 67% and Penrice as to 33% . o. The term of the JV will be a minimum of 6 years . o. SASS will provide a loan to Penrice of

Technical Support Document for the Soda Ash Manufacturing. Technical Support Document for the Soda Ash Manufacturing Sector: Proposed Rule for Mandatory Reporting of Greenhouse Gases Office. LIVE CHAT GET PRICE. PDF Natural Soda Ash Occurrences Process And Use . Browse and Read Natural Soda Ash Occurrences Process And Use. Title Type data processing and reconciliation for chemical process

Sodium Carbonate or Soda Ash-Na2CO3 Sodium Bicarbonate-NaHCO3 Sodium Sesquicarbonate, or Modified Soda Potassium Carbonate Oxygen-releasing Compounds Sundry Inorganic Builders Borax Sodium Chloride Magnesium Sulphate. www.entrepreneurindia.co Insoluble Inorganic Fillers Caustic Alkalis Ammonia Colloidal Silica Sodium Hypochlorite 3. Recent Developments in Surfactant …

Particulate emissions from soda ash manufacturing facilities in Wyoming are regulated in terms of total filterable and condensible particulate matter, with no regard to particle size; thus, available test data do not afford a particle size distribution.

One obvious reason for establishing caustic soda manufacturing operations in such close proximity to these larger plant complexes is the ready availability of the soda ash. Another is that the second reactant utilized in the causticization process; i.e., the lime, also is readily available from such soda ash manufacturing complexes as a co-product.

Making soda ash manufacture more sustainable. A modeling

RESEARCH ARTICLE 5 Utilization of Soda Ash in Pulping and

3 The Soda Ash is the basic inorganic raw material for manufacturing essential components of daily life. It is used in manufacture of :- float glasses, fiber glass, glass for Industrial use.

manufacturing process of soda ash. The mathematical model and the simulation The mathematical model and the simulation results proved to be a reliable tool for analyzing and optimizing the real plant

Soda Ash Dense (commonly known as sodium carbonate) is a white powder designed for use in powdered detergents and cleaners, chemical processes, …

Soda ash, also known as sodium carbonate (Na2CO3), is an alkali chemical refined from the mineral trona or naturally occurring sodium carbonate-bearing brines (both referred to as natural soda ash), the mineral nahcolite (referred to as natural sodium bicarbonate, from which soda ash can be produced), or manufactured from one of several chemical processes (referred to as synthetic soda ash).

flow sheet diagram of crushing, Process Flow Diagram Of Jaggery Manufacturing Plant. sugar factory process flow chart wikipedia BINQ Mining . 2013 · Flow diagram of the soda ash plant. soda ash manufacturing process flow diagram – Crusher.

The manufacture of soda ash in the Arabian Gulf

Manufacturing of sodium carbonate by solvay process

6 Manufacturing Process 13 7 Flow Chart 16 8 Effluent Treatment Process 17 9 Flow Chart 17 Ferrous Ascorbate 10 Manufacturing Process 18 11 Flow Chart 22 12 Effluent Treatment Process 23 13 Flow Chart 24 Paracetamol – Granules 14 Manufacturing Process 25 15 Flow Chart 28 . Adroit Pharmaceuticals Pvt.Ltd. Manufacturing & Effluent Treatment Process Vil-Fetri, Nagpur. _____ …

Sodium Silicate Manufacturing Sand Soda Ash Fuel Furnace 24000F 50% Caustic Soda Water / Steam Dissolver Adjust Ratio And Solids Liquid Silicate Storage Dryer Granular Meta Silicates. 4 General Applications This list includes both major and minor uses for silicates. The uses noted illus-trate the wide range of applications for sodium silicates. Abrasive Wheels Absorbents Adhesives …

25/08/2018 · FMC Soda Ash Plant, Wyoming Chemical Technology. Soda ash can be mined as a hydrated ore and then processed into the required . The choice of either process depends upon the economics of mining as.

Soda ash is a key chemical for producing soap, paper making, baking soda production, and bleaching fabrics and paper. Origin of soda ash term The name “soda ash” is based on the principal historical method of obtaining alkali, which was by using water to extract it from ashes. The word “soda” (from the Middle Latin) originally referred to certain plants that grow in salt marshes; it was

25/05/2015 · MAKING OF SODIUM CARBONATE BY SOLVARY PROCESS. Sodium carbonate is known as washing soda or soda ash. It is commonly occurred as a crystalline heptahydrate which readily effloresces to form a white powder, the monohydrate.

16/04/2013 · The Solvay process or ammonia-soda process is the major industrial process for … The worldwide production of soda ash in 2005 has been estimated at 42 billion …. carbon dioxide bubbled up through a descending flow of brine, together with …

The electrolysis process produces 2.25 tonnes of 50% caustic soda with each tonne of chlorine. The primary raw material is common salt, usually in the form of underground deposits which are brought to the surface as a solution in a pumped high pressure water supply.

The Solvay Process (also known as the ammonia-soda process), developed in 1861, is the world’s major industrial process for the production of sodium carbonate (NaCO3), or soda ash. Solvay

slight increase in the soda, the less viscous the glass becomes and the more time in seconds the forming process has to form the bottle before the glass stiffens.

Module 3 Lecture 9 NPTEL

PROJECT EXPANSION OF SODA ASH CEMENT AND CAPTIVE

Sodium Carbonate or Soda Ash-Na2CO3 Sodium Bicarbonate-NaHCO3 Sodium Sesquicarbonate, or Modified Soda Potassium Carbonate Oxygen-releasing Compounds Sundry Inorganic Builders Borax Sodium Chloride Magnesium Sulphate. www.entrepreneurindia.co Insoluble Inorganic Fillers Caustic Alkalis Ammonia Colloidal Silica Sodium Hypochlorite 3. Recent Developments in Surfactant …

dense soda ash process flow diagram – cleanroominstruments.in. Soda ash production process flow diagram Production process and methods for A process for the production of dense soda ash the process comprising mechanically . get more info.

National carbon emissions from the industry process: Production of glass, soda ash, ammonia, calcium carbide and alumina Zhu Liu⇑ Resnick Sustainability Institute, California Institute of Technology, Pasadena, CA 91125, USA

Soda Ash Manufacturing Download as PDF, TXT or read online from Scribd

Technical Support Document for the Soda Ash Manufacturing. Technical Support Document for the Soda Ash Manufacturing Sector: Proposed Rule for Mandatory Reporting of Greenhouse Gases Office. LIVE CHAT GET PRICE. PDF Natural Soda Ash Occurrences Process And Use . Browse and Read Natural Soda Ash Occurrences Process And Use. Title Type data processing and reconciliation for chemical process

Sodium Silicate Manufacturing Sand Soda Ash Fuel Furnace 24000F 50% Caustic Soda Water / Steam Dissolver Adjust Ratio And Solids Liquid Silicate Storage Dryer Granular Meta Silicates. 4 General Applications This list includes both major and minor uses for silicates. The uses noted illus-trate the wide range of applications for sodium silicates. Abrasive Wheels Absorbents Adhesives …

Manufacturing sodium carbonate by the Solvay process: page 3 of 4 RSaC Light sodium carbonate (light ash) This is made by taking the filtered sodium hydrogencarbonate and heating it.

The process of obtaining soda ash is, in short, the secretion of a solution composed of water, sodium chloride, ammonia and carbon dioxide sparingly soluble salt of sodium bicarbonate (NaHCO 3 ), but remains in solution of ammonium chloride (NH 4 Cl).

process of mining soda ash fsimworld.org

PROdUCTION OF SOda aSh TIKZN

Soda ash, owing to its ability to control the furnace temperature necessary to melt silica makes it an essential element in glass manufacturing process. This application segment is expected to generate over 35 million tons by 2024 and is supposed to account for just under 50% of the entire demand.

Soda ash is a key chemical for producing soap, paper making, baking soda production, and bleaching fabrics and paper. Origin of soda ash term The name “soda ash” is based on the principal historical method of obtaining alkali, which was by using water to extract it from ashes.

The silica and soda ash are melted in a furnace at temperatures of 17000C – this is called the batch. Limestone is added to give glass its hard, smooth texture. The batch turns into a hot, thick liquid known as molten glass. Glass Recycling. Glass recycling tips Remove all lids or caps Rinse out bottles and jars www.logan.qld.gov.au a load to be rejected and sent to the landfill. The glass

soda ash for flat glass industry is the highest at 25%, followed by demand for container glass at 19%. The other sources of demand however, include soap / detergents, chemicals, and metals/mining, pulp and paper, and others. The 2013 world Soda Ash demand by region was led by Northeast Asia (mainly China) at 45%. Other import regions for Soda Ash demand included Europe, split into West Europe

Sodium Silicate Manufacturing Sand Soda Ash Fuel Furnace 24000F 50% Caustic Soda Water / Steam Dissolver Adjust Ratio And Solids Liquid Silicate Storage Dryer Granular Meta Silicates. 4 General Applications This list includes both major and minor uses for silicates. The uses noted illus-trate the wide range of applications for sodium silicates. Abrasive Wheels Absorbents Adhesives …

The Solvay process is used to produce Soda Ash, which nowadays is extensively used in the most companies all over the world. In this method, salt and limestone are used as the main raw materials and common for producing Soda Ash.

slight increase in the soda, the less viscous the glass becomes and the more time in seconds the forming process has to form the bottle before the glass stiffens.

En.wikipedia.org The Solvay process or ammonia-soda process is the major industrial process for the production of sodium carbonate (soda ash, Na 2 CO 3). The ammonia-soda process was developed into its modern form by Ernest Solvay during the 1860s.

limestone in a process known as the Solvay process. Soda ash is the most important high tonnage, low cost, reasonably pure, soluble alkali available to the industries as well to the laboratory.

for the soda ash production process, quantifying the amount of limestone available in the silo is essential for assuring continuous production. The APM 3DLevelScanner’s unique surface mapping technology supports this by delivering real-time volume measurements of the stored material and by generating a 3D image of the stored content allowing early detection of build- ups. This is the basis

Soda Ash Manufacturing VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH (1) Le Blanc Process This process was invented by Nicolas Le Blanc, a French man ,who in 1775, among several others submitted an outline of a process for making soda ash from common salt, in response to an offer of reward by the French academy in paris.

In the eighteenth century soda ash was produced by LeBlanc process based on roasting salt cake with carbon and limestone. The synthetic process for the manufacture of soda ash by ammonia soda process

The Manufacturing Process The manufacture of sodium hypochlorite bleach requires several steps. All the steps can be carried out at one large manufacturing facility, or the chlorine and caustic soda can be shipped from different plants to the reactor site. Both chlorine and caustic soda are hazardous chemicals and are transported according to strict regulations. Preparing the components 1

Soda-lime glass consists of sand, limestone, soda ash, and cullet (broken glass). The manufacture of such glass is in four phases: (1) preparation of raw material, (2) melting in a furnace, (3) forming and (4) finishing. Figure 11.15-1 is a diagram for typical glass manufacturing. The products of this industry are flat glass, container glass, and pressed and blown glass. The procedures for

Soda Ash Manufacturing Industry. Production of Sodium Carbonate / Soda Crystals/ Soda Ash / Washing Soda. Exploring Business Opportunity in Soda Ash Production Soda ash, also know

mining solvay process of copper auto-spec.co.za

Soda Ash Manufacturing Industry YouTube

Through innovative process development and results-oriented pilot testing, Veolia Water Technologies helped American Soda reach their goal to produce exceptional high-quality soda ash and high-purity sodium bicarbonate from natural nacholite deposits. An HPD® sodium carbonate monohydrate crystallization system and a unique HPD sodium bicarbonate crystallization system were the first of

Soda Ash Dense (commonly known as sodium carbonate) is a white powder designed for use in powdered detergents and cleaners, chemical processes, …

A soda ash manufacturing facility is any facility that produces soda ash by calcining trona, calcining sodium sesquicarbonate, or by using a liquid alkaline feedstock process that directly produces carbon

Glass production involves two main methods – the float glass process that produces sheet glass, and glassblowing that produces bottles and other containers. Contents 1 Glass container production

Technical Support Document for the Soda Ash Manufacturing. Technical Support Document for the Soda Ash Manufacturing Sector: Proposed Rule for Mandatory Reporting of Greenhouse Gases Office. LIVE CHAT GET PRICE. PDF Natural Soda Ash Occurrences Process And Use . Browse and Read Natural Soda Ash Occurrences Process And Use. Title Type data processing and reconciliation for chemical process

However, a soda ash manufacturing facility should report its annual trona consumption, number of soda ash manufacturing lines, fractional purity of trona consumed or soda ash produced, annual soda ash manufacturing, annual soda ash production capacity, electricity usage (kilowatt- …

Soda ash, the trade name for sodium carbonate (Na 2 CO 3), is a white, anhydrous, powdered or granular material. It is an essential raw material used in the manufacturing of glass, detergents chemicals and other industrial products.

Process for manufacturing a soda ash peroxygen Download PDF Info Publication number EP0364840B2. process hydrogen peroxide Prior art date 1988-10-06 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired – Lifetime Application number …

soda ash manufacturing process flow diagram by solvay process VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH several others submitted an outline of a process for making soda ash from impurities ,is sprayed from the

Particulate emissions from soda ash manufacturing facilities in Wyoming are regulated in terms of total filterable and condensible particulate matter, with no regard to particle size; thus, available test data do not afford a particle size distribution.

The electrolysis process produces 2.25 tonnes of 50% caustic soda with each tonne of chlorine. The primary raw material is common salt, usually in the form of underground deposits which are brought to the surface as a solution in a pumped high pressure water supply.

The process of obtaining soda ash is, in short, the secretion of a solution composed of water, sodium chloride, ammonia and carbon dioxide sparingly soluble salt of sodium bicarbonate (NaHCO 3 ), but remains in solution of ammonium chloride (NH 4 Cl).

A soda ash manufacturing facility is any facility that produces soda ash by calcining trona, calcining sodium sesquicarbonate, or by using a liquid alkaline feedstock process that directly produces carbon dioxide (CO. 2). In the context of the soda ash manufacturing sector, “calcining” means the thermal/chemical conversion

16/04/2013 · The Solvay process or ammonia-soda process is the major industrial process for … The worldwide production of soda ash in 2005 has been estimated at 42 billion …. carbon dioxide bubbled up through a descending flow of brine, together with …

SODIUM CARBONATE-SOLVAY PROCESS City Collegiate

Design-Build Soda Ash Crystallization Plant Veolia

20/12/2018 · Soda ash is the common name for sodium carbonate, a chemical compound frequently used in manufacturing, industry, and even around the house. Glass production is one of the primary uses for sodium carbonate.

Soda ash, also known as sodium carbonate (Na2CO3), is an alkali chemical refined from the mineral trona or naturally occurring sodium carbonate-bearing brines (both referred to as natural soda ash), the mineral nahcolite (referred to as natural sodium bicarbonate, from which soda ash can be produced), or manufactured from one of several chemical processes (referred to as synthetic soda ash).

25/08/2018 · FMC Soda Ash Plant, Wyoming Chemical Technology. Soda ash can be mined as a hydrated ore and then processed into the required . The choice of either process depends upon the economics of mining as.

Particulate emissions from soda ash manufacturing facilities in Wyoming are regulated in terms of total filterable and condensible particulate matter, with no regard to particle size; thus, available test data do not afford a particle size distribution.

chlor-alkali process needs huge amounts of electricity and electrical energy is a major input. The main pollutant outputs which are common to all three electrolytic processes are chlorine gas emissions to air, free oxidants to water, spent acids, cooling agents, and impurities removed

En.wikipedia.org The Solvay process or ammonia-soda process is the major industrial process for the production of sodium carbonate (soda ash, Na 2 CO 3). The ammonia-soda process was developed into its modern form by Ernest Solvay during the 1860s.

Foreword for Volume I Soda ash is an important global commodity with a strong possibility of increasing demand. For this reason, utilization of world sodium carbonate resources into the

Soda-lime glass consists of sand, limestone, soda ash, and cullet (broken glass). The manufacture of such glass is in four phases: (1) preparation of raw material, (2) melting in a furnace, (3) forming and (4) finishing. Figure 11.15-1 is a diagram for typical glass manufacturing. The products of this industry are flat glass, container glass, and pressed and blown glass. The procedures for

The silica and soda ash are melted in a furnace at temperatures of 17000C – this is called the batch. Limestone is added to give glass its hard, smooth texture. The batch turns into a hot, thick liquid known as molten glass. Glass Recycling. Glass recycling tips Remove all lids or caps Rinse out bottles and jars www.logan.qld.gov.au a load to be rejected and sent to the landfill. The glass

Process Flow Diagram Of Washing Soda spitsid.eu

Soda Ash Manufacturing Industry YouTube

25/05/2015 · MAKING OF SODIUM CARBONATE BY SOLVARY PROCESS. Sodium carbonate is known as washing soda or soda ash. It is commonly occurred as a crystalline heptahydrate which readily effloresces to form a white powder, the monohydrate.

Soda Ash Dense (commonly known as sodium carbonate) is a white powder designed for use in powdered detergents and cleaners, chemical processes, …

for the soda ash production process, quantifying the amount of limestone available in the silo is essential for assuring continuous production. The APM 3DLevelScanner’s unique surface mapping technology supports this by delivering real-time volume measurements of the stored material and by generating a 3D image of the stored content allowing early detection of build- ups. This is the basis

Soda ash, owing to its ability to control the furnace temperature necessary to melt silica makes it an essential element in glass manufacturing process. This application segment is expected to generate over 35 million tons by 2024 and is supposed to account for just under 50% of the entire demand.

6 Manufacturing Process 13 7 Flow Chart 16 8 Effluent Treatment Process 17 9 Flow Chart 17 Ferrous Ascorbate 10 Manufacturing Process 18 11 Flow Chart 22 12 Effluent Treatment Process 23 13 Flow Chart 24 Paracetamol – Granules 14 Manufacturing Process 25 15 Flow Chart 28 . Adroit Pharmaceuticals Pvt.Ltd. Manufacturing & Effluent Treatment Process Vil-Fetri, Nagpur. _____ …

The Effect of Raw Materials and Production Conditions on

soda ash ocurrenceschemical processes

Soda Ash Manufacturing Download as PDF, TXT or read online from Scribd

rock crushing machine design pdf ore process crushing . gt mining solutions gt rock crushing machine design pdf mining .por le gold crusher. More Details . Read More; simons cone crusher rebuild specs amroninternational. a crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.the earliest crushers were hand held stones, where the weight of the stone

16/04/2013 · The Solvay process or ammonia-soda process is the major industrial process for … The worldwide production of soda ash in 2005 has been estimated at 42 billion …. carbon dioxide bubbled up through a descending flow of brine, together with …

project: expansion of soda ash, cement and captive cogeneration power plant applicant: m/s. tata chemicals ltd. pre-feasibility report iii index s.no. content page no. 1 executive summary 1 2 introduction of the project/ background information 3-5 2.1 identification of project and project proponent 3 2.2 brief information about the project 3 2.3 need for the project and its importance to the

limestone in a process known as the Solvay process. Soda ash is the most important high tonnage, low cost, reasonably pure, soluble alkali available to the industries as well to the laboratory.

Through innovative process development and results-oriented pilot testing, Veolia Water Technologies helped American Soda reach their goal to produce exceptional high-quality soda ash and high-purity sodium bicarbonate from natural nacholite deposits. An HPD® sodium carbonate monohydrate crystallization system and a unique HPD sodium bicarbonate crystallization system were the first of

One obvious reason for establishing caustic soda manufacturing operations in such close proximity to these larger plant complexes is the ready availability of the soda ash. Another is that the second reactant utilized in the causticization process; i.e., the lime, also is readily available from such soda ash manufacturing complexes as a co-product.

The Solvay process is used to produce Soda Ash, which nowadays is extensively used in the most companies all over the world. In this method, salt and limestone are used as the main raw materials and common for producing Soda Ash.

Interesting facts about Soda ash / Washing soda / Sodium

Tata Chemicals Mithapur ibm.gov.in

Through innovative process development and results-oriented pilot testing, Veolia Water Technologies helped American Soda reach their goal to produce exceptional high-quality soda ash and high-purity sodium bicarbonate from natural nacholite deposits. An HPD® sodium carbonate monohydrate crystallization system and a unique HPD sodium bicarbonate crystallization system were the first of

limestone in a process known as the Solvay process. Soda ash is the most important high tonnage, low cost, reasonably pure, soluble alkali available to the industries as well to the laboratory.

3 The Soda Ash is the basic inorganic raw material for manufacturing essential components of daily life. It is used in manufacture of :- float glasses, fiber glass, glass for Industrial use.

Soda Ash Dense (commonly known as sodium carbonate) is a white powder designed for use in powdered detergents and cleaners, chemical processes, …

The Sodium Bicarbonate produced via this process is then converted to the commercially important chemical Sodium Carbonate; also known as Soda Ash (Na 2 CO 3) or Washing Soda (Na 2 CO 3•10H 2 O). 2 NaHCO 3 (s) Na 2 CO 3 (s) CO 2 (g) H 2 O(g) By 1890, most of the Soda Ash produced worldwide was produced as a result of the Solvay Process. Currently, three-quarters of the worldwide

However, a soda ash manufacturing facility should report its annual trona consumption, number of soda ash manufacturing lines, fractional purity of trona consumed or soda ash produced, annual soda ash manufacturing, annual soda ash production capacity, electricity usage (kilowatt- …

Soda ash is a key chemical for producing soap, paper making, baking soda production, and bleaching fabrics and paper. Origin of soda ash term The name “soda ash” is based on the principal historical method of obtaining alkali, which was by using water to extract it from ashes. The word “soda” (from the Middle Latin) originally referred to certain plants that grow in salt marshes; it was

This paper is concerned with the technical and economic aspects of the soda ash production in the Arabian Gulf. Five different manufacturing methods are outlined.

Soda Ash Manufacturing Industry Sodium Carbonate

Tata Chemicals Mithapur ibm.gov.in

Soda ash is a key chemical for producing soap, paper making, baking soda production, and bleaching fabrics and paper. Origin of soda ash term The name “soda ash” is based on the principal historical method of obtaining alkali, which was by using water to extract it from ashes.

The Manufacturing Process The manufacture of sodium hypochlorite bleach requires several steps. All the steps can be carried out at one large manufacturing facility, or the chlorine and caustic soda can be shipped from different plants to the reactor site. Both chlorine and caustic soda are hazardous chemicals and are transported according to strict regulations. Preparing the components 1

The Sodium Bicarbonate produced via this process is then converted to the commercially important chemical Sodium Carbonate; also known as Soda Ash (Na 2 CO 3) or Washing Soda (Na 2 CO 3•10H 2 O). 2 NaHCO 3 (s) Na 2 CO 3 (s) CO 2 (g) H 2 O(g) By 1890, most of the Soda Ash produced worldwide was produced as a result of the Solvay Process. Currently, three-quarters of the worldwide

Soda Ash Manufacturing VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH (1) Le Blanc Process This process was invented by Nicolas Le Blanc, a French man ,who in 1775, among several others submitted an outline of a process for making soda ash from common salt, in response to an offer of reward by the French academy in paris.

Production of Soda Ash and downstream products (beneficiation of limestone) Project Concept ` completed The establishment of a synthetic Soda Ash manufacturing plant in southern KwaZulu-Natal (Hibiscus Municipality) ` Soda Ash products are currently being imported into South Africa. Soda Ash (sodium carbonate) plays a significant role as a strategic feed material for the manufacture of

Foreword for Volume I Soda ash is an important global commodity with a strong possibility of increasing demand. For this reason, utilization of world sodium carbonate resources into the

The silica and soda ash are melted in a furnace at temperatures of 17000C – this is called the batch. Limestone is added to give glass its hard, smooth texture. The batch turns into a hot, thick liquid known as molten glass. Glass Recycling. Glass recycling tips Remove all lids or caps Rinse out bottles and jars www.logan.qld.gov.au a load to be rejected and sent to the landfill. The glass

The aim of the project was to study the manufacturing of synthetic soda ash (sodium carbonate, Na2CO3) on an industrial scale. Currently all Soda ash that is used in South Africa for manufacturing glass is imported at a high cost, and the company Nampak Wiegand Glass (South Africa) is investigating the possibility to locally manufacture

Abstract— Soda ash or sodium carbonate is by nature a weak base and hence lower in alkalinity. The agro based pulp and paper mill with unconventional chemical recovery process end up with production of soda ash or sodium carbonate. The soda ash thus produced is of low quality and sold to soap manufacturing units. The pulping and bleaching process requires at some stage low alkalinity where

The electrolysis process produces 2.25 tonnes of 50% caustic soda with each tonne of chlorine. The primary raw material is common salt, usually in the form of underground deposits which are brought to the surface as a solution in a pumped high pressure water supply.

National carbon emissions from the industry process: Production of glass, soda ash, ammonia, calcium carbide and alumina Zhu Liu⇑ Resnick Sustainability Institute, California Institute of Technology, Pasadena, CA 91125, USA

To counter this effect , lower part of Solvay tower is cooled , ppt of NaHCO 3 are separated by vacuum filtration and washed to remove ammonium salts. Conversion of NaHCO 3 to Na 2 CO 3 Dry sodium bicarbonate is heated in rotary furnace called ” CALCINER ” to give anhydrous sodium carbonate or soda ash.

About Soda Ash ANSAC

Soda Ash Manufacturing Industry Sodium Carbonate

The Sodium Bicarbonate produced via this process is then converted to the commercially important chemical Sodium Carbonate; also known as Soda Ash (Na 2 CO 3) or Washing Soda (Na 2 CO 3•10H 2 O). 2 NaHCO 3 (s) Na 2 CO 3 (s) CO 2 (g) H 2 O(g) By 1890, most of the Soda Ash produced worldwide was produced as a result of the Solvay Process. Currently, three-quarters of the worldwide

16/04/2013 · The Solvay process or ammonia-soda process is the major industrial process for … The worldwide production of soda ash in 2005 has been estimated at 42 billion …. carbon dioxide bubbled up through a descending flow of brine, together with …

Sodium Carbonate or Soda Ash-Na2CO3 Sodium Bicarbonate-NaHCO3 Sodium Sesquicarbonate, or Modified Soda Potassium Carbonate Oxygen-releasing Compounds Sundry Inorganic Builders Borax Sodium Chloride Magnesium Sulphate. www.entrepreneurindia.co Insoluble Inorganic Fillers Caustic Alkalis Ammonia Colloidal Silica Sodium Hypochlorite 3. Recent Developments in Surfactant …

20/12/2018 · Soda ash is the common name for sodium carbonate, a chemical compound frequently used in manufacturing, industry, and even around the house. Glass production is one of the primary uses for sodium carbonate.

soda ash for flat glass industry is the highest at 25%, followed by demand for container glass at 19%. The other sources of demand however, include soap / detergents, chemicals, and metals/mining, pulp and paper, and others. The 2013 world Soda Ash demand by region was led by Northeast Asia (mainly China) at 45%. Other import regions for Soda Ash demand included Europe, split into West Europe

Soda Ash Manufacturing VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH (1) Le Blanc Process This process was invented by Nicolas Le Blanc, a French man ,who in 1775, among several others submitted an outline of a process for making soda ash from common salt, in response to an offer of reward by the French academy in paris.

The Solvay Process (also known as the ammonia-soda process), developed in 1861, is the world’s major industrial process for the production of sodium carbonate (NaCO3), or soda ash. Solvay

Abstract— Soda ash or sodium carbonate is by nature a weak base and hence lower in alkalinity. The agro based pulp and paper mill with unconventional chemical recovery process end up with production of soda ash or sodium carbonate. The soda ash thus produced is of low quality and sold to soap manufacturing units. The pulping and bleaching process requires at some stage low alkalinity where

En.wikipedia.org The Solvay process or ammonia-soda process is the major industrial process for the production of sodium carbonate (soda ash, Na 2 CO 3). The ammonia-soda process was developed into its modern form by Ernest Solvay during the 1860s.

for the soda ash production process, quantifying the amount of limestone available in the silo is essential for assuring continuous production. The APM 3DLevelScanner’s unique surface mapping technology supports this by delivering real-time volume measurements of the stored material and by generating a 3D image of the stored content allowing early detection of build- ups. This is the basis

This paper is concerned with the technical and economic aspects of the soda ash production in the Arabian Gulf. Five different manufacturing methods are outlined.

This is known as the Solvay process and was the main source of soda ash until the Wyoming trona deposits were discovered. However, it is more expensive than mining natural sodium carbonate deposits. However, it is more expensive than mining natural sodium carbonate deposits.

BACKGROUND REPORT AP-42 SECTION 5.16 SODIUM

soda ash manufacturing process flow diagram ellul.nl

soda ash manufacturing process flow diagram by solvay process VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH several others submitted an outline of a process for making soda ash from impurities ,is sprayed from the

20/12/2018 · Soda ash is the common name for sodium carbonate, a chemical compound frequently used in manufacturing, industry, and even around the house. Glass production is one of the primary uses for sodium carbonate.

The silica and soda ash are melted in a furnace at temperatures of 17000C – this is called the batch. Limestone is added to give glass its hard, smooth texture. The batch turns into a hot, thick liquid known as molten glass. Glass Recycling. Glass recycling tips Remove all lids or caps Rinse out bottles and jars www.logan.qld.gov.au a load to be rejected and sent to the landfill. The glass

Glass production involves two main methods – the float glass process that produces sheet glass, and glassblowing that produces bottles and other containers. Contents 1 Glass container production

Soda ash, also known as sodium carbonate (Na2CO3), is an alkali chemical refined from the mineral trona or naturally occurring sodium carbonate-bearing brines (both referred to as natural soda ash), the mineral nahcolite (referred to as natural sodium bicarbonate, from which soda ash can be produced), or manufactured from one of several chemical processes (referred to as synthetic soda ash).

Solvay Process make Sodium carbonate in chemical . The Solvay Process (also known as the ammonia-soda process), developed in 1861, is the world’s major industrial process for the production of sodium carbonate (NaCO 3), or soda ash.

KAVEH > Products > Soda Ash

Continuous process of sodium bicarbonate production by

project: expansion of soda ash, cement and captive cogeneration power plant applicant: m/s. tata chemicals ltd. pre-feasibility report iii index s.no. content page no. 1 executive summary 1 2 introduction of the project/ background information 3-5 2.1 identification of project and project proponent 3 2.2 brief information about the project 3 2.3 need for the project and its importance to the

Soda Ash Manufacturing Industry. Production of Sodium Carbonate / Soda Crystals/ Soda Ash / Washing Soda. Exploring Business Opportunity in Soda Ash Production Soda ash, also know

To counter this effect , lower part of Solvay tower is cooled , ppt of NaHCO 3 are separated by vacuum filtration and washed to remove ammonium salts. Conversion of NaHCO 3 to Na 2 CO 3 Dry sodium bicarbonate is heated in rotary furnace called ” CALCINER ” to give anhydrous sodium carbonate or soda ash.

The aim of the project was to study the manufacturing of synthetic soda ash (sodium carbonate, Na2CO3) on an industrial scale. Currently all Soda ash that is used in South Africa for manufacturing glass is imported at a high cost, and the company Nampak Wiegand Glass (South Africa) is investigating the possibility to locally manufacture

25/05/2015 · MAKING OF SODIUM CARBONATE BY SOLVARY PROCESS. Sodium carbonate is known as washing soda or soda ash. It is commonly occurred as a crystalline heptahydrate which readily effloresces to form a white powder, the monohydrate.

Soda Ash Manufacturing VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH (1) Le Blanc Process This process was invented by Nicolas Le Blanc, a French man ,who in 1775, among several others submitted an outline of a process for making soda ash from common salt, in response to an offer of reward by the French academy in paris.

dense soda ash process flow diagram – cleanroominstruments.in. Soda ash production process flow diagram Production process and methods for A process for the production of dense soda ash the process comprising mechanically . get more info.

RESEARCH ARTICLE 5 Utilization of Soda Ash in Pulping and

mining solvay process of copper auto-spec.co.za

Soda Ash Dense (commonly known as sodium carbonate) is a white powder designed for use in powdered detergents and cleaners, chemical processes, …

One obvious reason for establishing caustic soda manufacturing operations in such close proximity to these larger plant complexes is the ready availability of the soda ash. Another is that the second reactant utilized in the causticization process; i.e., the lime, also is readily available from such soda ash manufacturing complexes as a co-product.

rock crushing machine design pdf ore process crushing . gt mining solutions gt rock crushing machine design pdf mining .por le gold crusher. More Details . Read More; simons cone crusher rebuild specs amroninternational. a crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.the earliest crushers were hand held stones, where the weight of the stone

Technical Support Document for the Soda Ash Manufacturing. Technical Support Document for the Soda Ash Manufacturing Sector: Proposed Rule for Mandatory Reporting of Greenhouse Gases Office. LIVE CHAT GET PRICE. PDF Natural Soda Ash Occurrences Process And Use . Browse and Read Natural Soda Ash Occurrences Process And Use. Title Type data processing and reconciliation for chemical process

The Solvay process is used to produce Soda Ash, which nowadays is extensively used in the most companies all over the world. In this method, salt and limestone are used as the main raw materials and common for producing Soda Ash.

A soda ash manufacturing facility is any facility that produces soda ash by calcining trona, calcining sodium sesquicarbonate, or by using a liquid alkaline feedstock process that directly produces carbon

The Manufacturing Process The manufacture of sodium hypochlorite bleach requires several steps. All the steps can be carried out at one large manufacturing facility, or the chlorine and caustic soda can be shipped from different plants to the reactor site. Both chlorine and caustic soda are hazardous chemicals and are transported according to strict regulations. Preparing the components 1

Soda ash is a key chemical for producing soap, paper making, baking soda production, and bleaching fabrics and paper. Origin of soda ash term The name “soda ash” is based on the principal historical method of obtaining alkali, which was by using water to extract it from ashes. The word “soda” (from the Middle Latin) originally referred to certain plants that grow in salt marshes; it was

Foreword for Volume I Soda ash is an important global commodity with a strong possibility of increasing demand. For this reason, utilization of world sodium carbonate resources into the

soda ash ocurrenceschemical processes

Solvay process Wikipedia

chlor-alkali process needs huge amounts of electricity and electrical energy is a major input. The main pollutant outputs which are common to all three electrolytic processes are chlorine gas emissions to air, free oxidants to water, spent acids, cooling agents, and impurities removed

However, a soda ash manufacturing facility should report its annual trona consumption, number of soda ash manufacturing lines, fractional purity of trona consumed or soda ash produced, annual soda ash manufacturing, annual soda ash production capacity, electricity usage (kilowatt- …

Process for manufacturing a soda ash peroxygen Download PDF Info Publication number EP0364840B2. process hydrogen peroxide Prior art date 1988-10-06 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired – Lifetime Application number …

Through innovative process development and results-oriented pilot testing, Veolia Water Technologies helped American Soda reach their goal to produce exceptional high-quality soda ash and high-purity sodium bicarbonate from natural nacholite deposits. An HPD® sodium carbonate monohydrate crystallization system and a unique HPD sodium bicarbonate crystallization system were the first of

The silica and soda ash are melted in a furnace at temperatures of 17000C – this is called the batch. Limestone is added to give glass its hard, smooth texture. The batch turns into a hot, thick liquid known as molten glass. Glass Recycling. Glass recycling tips Remove all lids or caps Rinse out bottles and jars www.logan.qld.gov.au a load to be rejected and sent to the landfill. The glass

limestone in a process known as the Solvay process. Soda ash is the most important high tonnage, low cost, reasonably pure, soluble alkali available to the industries as well to the laboratory.

soda ash manufacturing process flow diagram by solvay process VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH several others submitted an outline of a process for making soda ash from impurities ,is sprayed from the

project: expansion of soda ash, cement and captive cogeneration power plant applicant: m/s. tata chemicals ltd. pre-feasibility report iii index s.no. content page no. 1 executive summary 1 2 introduction of the project/ background information 3-5 2.1 identification of project and project proponent 3 2.2 brief information about the project 3 2.3 need for the project and its importance to the

Soda-lime glass consists of sand, limestone, soda ash, and cullet (broken glass). The manufacture of such glass is in four phases: (1) preparation of raw material, (2) melting in a furnace, (3) forming and (4) finishing. Figure 11.15-1 is a diagram for typical glass manufacturing. The products of this industry are flat glass, container glass, and pressed and blown glass. The procedures for

The Manufacturing Process The manufacture of sodium hypochlorite bleach requires several steps. All the steps can be carried out at one large manufacturing facility, or the chlorine and caustic soda can be shipped from different plants to the reactor site. Both chlorine and caustic soda are hazardous chemicals and are transported according to strict regulations. Preparing the components 1

Soda ash is a key chemical for producing soap, paper making, baking soda production, and bleaching fabrics and paper. Origin of soda ash term The name “soda ash” is based on the principal historical method of obtaining alkali, which was by using water to extract it from ashes.

20/12/2018 · Soda ash is the common name for sodium carbonate, a chemical compound frequently used in manufacturing, industry, and even around the house. Glass production is one of the primary uses for sodium carbonate.

Soda ash is a key chemical for producing soap, paper making, baking soda production, and bleaching fabrics and paper. Origin of soda ash term The name “soda ash” is based on the principal historical method of obtaining alkali, which was by using water to extract it from ashes. The word “soda” (from the Middle Latin) originally referred to certain plants that grow in salt marshes; it was

Glass production involves two main methods – the float glass process that produces sheet glass, and glassblowing that produces bottles and other containers. Contents 1 Glass container production

Penrice forms joint venture to resell and distribute soda ash

PREPARATION OF SODIUM CARBONATE BY SOLVAY PROCESS

Abstract— Soda ash or sodium carbonate is by nature a weak base and hence lower in alkalinity. The agro based pulp and paper mill with unconventional chemical recovery process end up with production of soda ash or sodium carbonate. The soda ash thus produced is of low quality and sold to soap manufacturing units. The pulping and bleaching process requires at some stage low alkalinity where

The process of obtaining soda ash is, in short, the secretion of a solution composed of water, sodium chloride, ammonia and carbon dioxide sparingly soluble salt of sodium bicarbonate (NaHCO 3 ), but remains in solution of ammonium chloride (NH 4 Cl).

Sodium Carbonate or Soda Ash-Na2CO3 Sodium Bicarbonate-NaHCO3 Sodium Sesquicarbonate, or Modified Soda Potassium Carbonate Oxygen-releasing Compounds Sundry Inorganic Builders Borax Sodium Chloride Magnesium Sulphate. www.entrepreneurindia.co Insoluble Inorganic Fillers Caustic Alkalis Ammonia Colloidal Silica Sodium Hypochlorite 3. Recent Developments in Surfactant …

Soda Ash Manufacturing Industry. Production of Sodium Carbonate / Soda Crystals/ Soda Ash / Washing Soda. Exploring Business Opportunity in Soda Ash Production Soda ash, also know

dense soda ash process flow diagram – cleanroominstruments.in. Soda ash production process flow diagram Production process and methods for A process for the production of dense soda ash the process comprising mechanically . get more info.

soda ash manufacturing process flow diagram by solvay use of ammonia still in solvay process flow diagram The conveyancing process explained in a simple flow Chat Online Draw The Flow Sheet Iron Ore Wet Processing Plant Showing Steps From process flow diagram by solvay is a basic diagram on Iron Ore flow sheet Chat Online soda ash

Soda-lime glass consists of sand, limestone, soda ash, and cullet (broken glass). The manufacture of such glass is in four phases: (1) preparation of raw material, (2) melting in a furnace, (3) forming and (4) finishing. Figure 11.15-1 is a diagram for typical glass manufacturing. The products of this industry are flat glass, container glass, and pressed and blown glass. The procedures for

Soda ash Soda crystal Washing soda . Product Overview . Solvay Chemicals, Inc. does not sell sodium carbonate directly to consumers. Consumers may be exposed to sodium carbonate in many consumer product applications where the sodium carbonate is not transformed or reacted and is present in powder or granule form. Sodium carbonate is a white, granular or powdered solid. It is used …

In this study, we quantified the industrial process emissions from the production of alumina, plate glass, soda ash, ammonia and calcium carbide. The total emissions from the industrial processing of these five products reached 233 Mt CO 2 in 2013.

25/08/2018 · FMC Soda Ash Plant, Wyoming Chemical Technology. Soda ash can be mined as a hydrated ore and then processed into the required . The choice of either process depends upon the economics of mining as.

A soda ash manufacturing facility is any facility that produces soda ash by calcining trona, calcining sodium sesquicarbonate, or by using a liquid alkaline feedstock process that directly produces carbon dioxide (CO. 2). In the context of the soda ash manufacturing sector, “calcining” means the thermal/chemical conversion

limestone in a process known as the Solvay process. Soda ash is the most important high tonnage, low cost, reasonably pure, soluble alkali available to the industries as well to the laboratory.

soda ash manufacturing process flow diagram by solvay process VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH several others submitted an outline of a process for making soda ash from impurities ,is sprayed from the

The Solvay process is used to produce Soda Ash, which nowadays is extensively used in the most companies all over the world. In this method, salt and limestone are used as the main raw materials and common for producing Soda Ash.

manufacturing process of soda ash. The mathematical model and the simulation The mathematical model and the simulation results proved to be a reliable tool for analyzing and optimizing the real plant

mining solvay process of copper auto-spec.co.za

Interesting facts about Soda ash / Washing soda / Sodium

The aim of the project was to study the manufacturing of synthetic soda ash (sodium carbonate, Na2CO3) on an industrial scale. Currently all Soda ash that is used in South Africa for manufacturing glass is imported at a high cost, and the company Nampak Wiegand Glass (South Africa) is investigating the possibility to locally manufacture

rock crushing machine design pdf ore process crushing . gt mining solutions gt rock crushing machine design pdf mining .por le gold crusher. More Details . Read More; simons cone crusher rebuild specs amroninternational. a crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.the earliest crushers were hand held stones, where the weight of the stone

soda ash for flat glass industry is the highest at 25%, followed by demand for container glass at 19%. The other sources of demand however, include soap / detergents, chemicals, and metals/mining, pulp and paper, and others. The 2013 world Soda Ash demand by region was led by Northeast Asia (mainly China) at 45%. Other import regions for Soda Ash demand included Europe, split into West Europe

Through innovative process development and results-oriented pilot testing, Veolia Water Technologies helped American Soda reach their goal to produce exceptional high-quality soda ash and high-purity sodium bicarbonate from natural nacholite deposits. An HPD® sodium carbonate monohydrate crystallization system and a unique HPD sodium bicarbonate crystallization system were the first of

16/04/2013 · The Solvay process or ammonia-soda process is the major industrial process for … The worldwide production of soda ash in 2005 has been estimated at 42 billion …. carbon dioxide bubbled up through a descending flow of brine, together with …

the ammonium chloride and soda ash dual manufacturing

Solvay Process Make Sodium Carbonate in Chemical

How bleach is made material manufacture making

To counter this effect , lower part of Solvay tower is cooled , ppt of NaHCO 3 are separated by vacuum filtration and washed to remove ammonium salts. Conversion of NaHCO 3 to Na 2 CO 3 Dry sodium bicarbonate is heated in rotary furnace called ” CALCINER ” to give anhydrous sodium carbonate or soda ash.

Soda ash manufacturing process” Keyword Found Websites

About Soda Ash ANSAC

project: expansion of soda ash, cement and captive cogeneration power plant applicant: m/s. tata chemicals ltd. pre-feasibility report iii index s.no. content page no. 1 executive summary 1 2 introduction of the project/ background information 3-5 2.1 identification of project and project proponent 3 2.2 brief information about the project 3 2.3 need for the project and its importance to the

Soda Ash Production apm-solutions.com

Tata Chemicals Mithapur ibm.gov.in

The Sodium Bicarbonate produced via this process is then converted to the commercially important chemical Sodium Carbonate; also known as Soda Ash (Na 2 CO 3) or Washing Soda (Na 2 CO 3•10H 2 O). 2 NaHCO 3 (s) Na 2 CO 3 (s) + CO 2 (g) + H 2 O(g) By 1890, most of the Soda Ash produced worldwide was produced as a result of the Solvay Process. Currently, three-quarters of the worldwide

EP0364840B2 Process for manufacturing a soda ash

Manufacturing of synthetic soda ash ETD Home

To counter this effect , lower part of Solvay tower is cooled , ppt of NaHCO 3 are separated by vacuum filtration and washed to remove ammonium salts. Conversion of NaHCO 3 to Na 2 CO 3 Dry sodium bicarbonate is heated in rotary furnace called ” CALCINER ” to give anhydrous sodium carbonate or soda ash.

PROdUCTION OF SOda aSh TIKZN

How to Manufacture Detergents Powder Active Ingredients

The electrolysis process produces 2.25 tonnes of 50% caustic soda with each tonne of chlorine. The primary raw material is common salt, usually in the form of underground deposits which are brought to the surface as a solution in a pumped high pressure water supply.

Manufacturing of synthetic soda ash ETD Home

soda ash ocurrenceschemical processes

dense soda ash process flow diagram – cleanroominstruments.in. Soda ash production process flow diagram Production process and methods for A process for the production of dense soda ash the process comprising mechanically . get more info.

Continuous process of sodium bicarbonate production by

(PDF) The manufacture of soda ash in the Arabian Gulf

Soda Ash Dense (commonly known as sodium carbonate) is a white powder designed for use in powdered detergents and cleaners, chemical processes, …

PROdUCTION OF SOda aSh TIKZN

The Manufacturing Process The manufacture of sodium hypochlorite bleach requires several steps. All the steps can be carried out at one large manufacturing facility, or the chlorine and caustic soda can be shipped from different plants to the reactor site. Both chlorine and caustic soda are hazardous chemicals and are transported according to strict regulations. Preparing the components 1

M Caustic Soda Handbook oxy.com

the ammonium chloride and soda ash dual manufacturing

BACKGROUND REPORT AP-42 SECTION 5.16 SODIUM

limestone in a process known as the Solvay process. Soda ash is the most important high tonnage, low cost, reasonably pure, soluble alkali available to the industries as well to the laboratory.

KAVEH > Products > Soda Ash

the ammonium chloride and soda ash dual manufacturing process in japan Download the ammonium chloride and soda ash dual manufacturing process in japan or read online books in PDF, EPUB, Tuebl, and Mobi Format.

Process Flow Diagram Of Washing Soda spitsid.eu

Soda Ash Manufacturing US EPA

Soda Ash Manufacturing VARIOUS CHEMICAL PROCESSES PRODUCTION OF SODA ASH (1) Le Blanc Process This process was invented by Nicolas Le Blanc, a French man ,who in 1775, among several others submitted an outline of a process for making soda ash from common salt, in response to an offer of reward by the French academy in paris.

(PDF) The manufacture of soda ash in the Arabian Gulf

Tata Chemicals Mithapur ibm.gov.in

Soda ash, the trade name for sodium carbonate (Na 2 CO 3), is a white, anhydrous, powdered or granular material. It is an essential raw material used in the manufacturing of glass, detergents chemicals and other industrial products.

How to Manufacture Detergents Powder Active Ingredients

This paper is concerned with the technical and economic aspects of the soda ash production in the Arabian Gulf. Five different manufacturing methods are outlined.

Soda Ash Production apm-solutions.com

The Effect of Raw Materials and Production Conditions on

Soda-lime glass consists of sand, limestone, soda ash, and cullet (broken glass). The manufacture of such glass is in four phases: (1) preparation of raw material, (2) melting in a furnace, (3) forming and (4) finishing. Figure 11.15-1 is a diagram for typical glass manufacturing. The products of this industry are flat glass, container glass, and pressed and blown glass. The procedures for

PROJECT EXPANSION OF SODA ASH CEMENT AND CAPTIVE

SODIUM CARBONATE-SOLVAY PROCESS City Collegiate

What is Soda Ash? (with pictures) wisegeek.com

Soda ash, owing to its ability to control the furnace temperature necessary to melt silica makes it an essential element in glass manufacturing process. This application segment is expected to generate over 35 million tons by 2024 and is supposed to account for just under 50% of the entire demand.

How to Manufacture Detergents Powder Active Ingredients

Particulate emissions from soda ash manufacturing facilities in Wyoming are regulated in terms of total filterable and condensible particulate matter, with no regard to particle size; thus, available test data do not afford a particle size distribution.

the ammonium chloride and soda ash dual manufacturing

Particulate emissions from soda ash manufacturing facilities in Wyoming are regulated in terms of total filterable and condensible particulate matter, with no regard to particle size; thus, available test data do not afford a particle size distribution.

the ammonium chloride and soda ash dual manufacturing

project: expansion of soda ash, cement and captive cogeneration power plant applicant: m/s. tata chemicals ltd. pre-feasibility report iii index s.no. content page no. 1 executive summary 1 2 introduction of the project/ background information 3-5 2.1 identification of project and project proponent 3 2.2 brief information about the project 3 2.3 need for the project and its importance to the

How to Manufacture Detergents Powder Active Ingredients

The Solvay process or ammonia-soda process is the major industrial process for the production of sodium carbonate (soda ash, Na 2 CO 3). The ammonia-soda process was developed into its modern form by Ernest Solvay during the 1860s.

Module 3 Lecture 9 NPTEL

National carbon emissions from the industry process

Design-Build Soda Ash Crystallization Plant Veolia