Packed bed reactor design pdf

It is usually treated in reactor design and operational practice in terms of “SPACE VELOCITY”. Spacie velocity is defined as the volume of gas (@ standard temperature and pressure) or liquid passing through a fixed volume of catalyst space, v C , in unit time divided by the latter.

© 2013 Process Systems Enterprise Limited Alejandro Cano Head of Consulting, Process Systems Enterprise Model-based design, scale-up, and operational optimization of

PACKED BED REACTOR SIMULATION FOR ACETALDEHYDE PRODUCTION BY ORTHOGONAL COLLOCATION Oscar Sánchez, Hugo Galindo, Ivan Gil, Gustavo Orozco Departamento de Ingeniería Química, Universidad Nacional de Colombia

Cells of Clostridium acetobutylicum were immobilized by adsorption onto bonechar, and used in a packed bed or fluidized bed reactor for continuous production …

Multiphysics Simulation of a Packed Bed Reactor . Alfredo E Varela * University of Carabobo, Valencia, Venezuela 2001 and Juan C García *Email: avarela@uc.edu.ve. Abstract: Most reactor designs are based on pseudo homogeneous models. This paper studies the COMSOL simulation of a packed bed reactor using a 2-D heterogeneous model. The inter-pellet regions have been …

This paper deals with the design and operation strategies of dynamically operated packed-bed reactors (PBRs) of a chemical looping combustion (CLC) system included in an integrated gasification combined

design of packed tower.pdf . pressure drop through packed bed . design of a packed bed reactor. Design of Column . RCC structural Design. Design of Column Bases . Design of Column Bases . Experiment 2 – Study of Packed Column Distillation . chemical engineering lab. Packed Columns Vs tray column . Gives idea of when tray or packed columns are used in distillation column. Column Design . Design

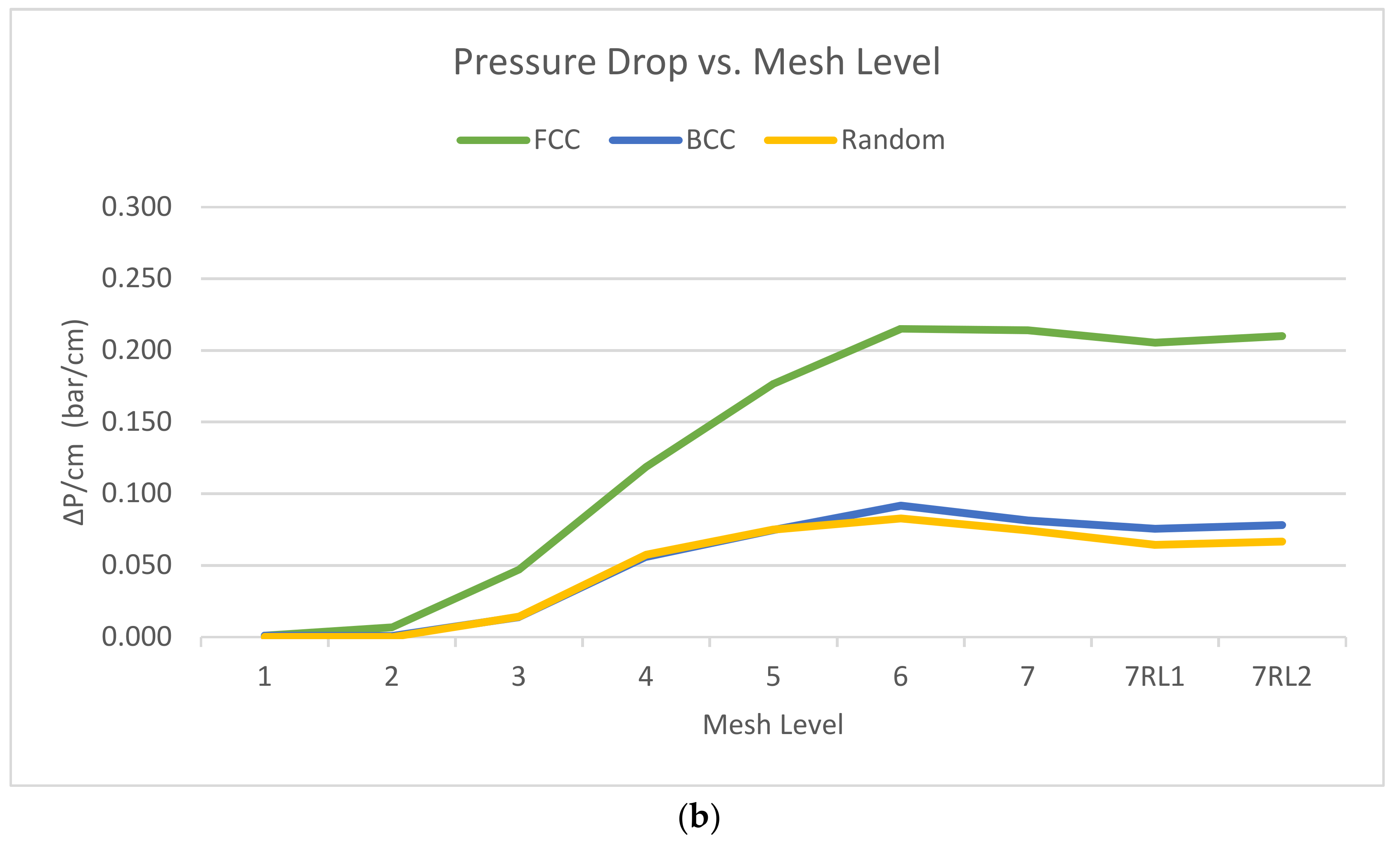

the packed bed. This information is useful in determining how pressure will change when scaling up This information is useful in determining how pressure will change when scaling up reactors …

CHAPTER 4 PACKED BED REACTOR 4.1 INTRODUCTION For the final polishing ofthe ret liquor (effluent) after the treatment in the activated sludge system a packed bed reactor …

PACKED BED REACTOR SIMULATION FOR ACETALDEHYDE PRODUCTION

NASA Packed Bed Reactor Experiment

An Expanded Granular Sludge Bed (EGSB) reactor was used to cultivate the granular sludge and to perform the ANAMMOX reaction in the bench scale experiment. NH4(+)-N …

design of novel catalytic reactors. micro-reaction engineering is an emerging field, Figure 1: Packed Bed Reactor A fixed or packed bed is an assembly of randomly arranged particles that are bathed by the reactant fluid, which flows in random manner around the pellets. A schematic representation of fixed bed reactor is shown in Figure 1. Catalytic fixed bed reactors find wide spread use in

External & Internal Diffusion 1. Diffusion Fundamentals Consider a tubular-typed reactor, where the molar flow rate of reaction mixture in the z-direction is

11.2 Packed Bed Reactor Design 955 processes and not applicable for very exothermic or endothermic processes. If the reaction is very endothermic, the temperature change may be such as

5 Chapter 5: Fixed Bed Reactor Design, Construction and Performance 5.1 Introduction The investigation of the decomposition of sulphur trioxide to sulphur dioxide and oxygen using a packed

The optimum reactor that will best meet the process requirements requires a review of whether the physical configuration is continuous, batch, tubular or catalytic reactors such as the fixed and fluidized beds.

Air Pollution Control Technology Fact Sheet EPA-CICA Fact Sheet Packed-Bed/Packed-Tower Scrubber1 Such data are necessary for the design of absorber systems; however, they are not readily available for uncommon organic compounds. EPA-CICA Fact Sheet Packed-Bed/Packed-Tower Scrubber4 The solvent chosen to remove the pollutant(s) should have a high solubility for the vapor …

Fixed-Bed Catalytic Reactor – Download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world’s largest social reading and publishing site.

The catalyst weight and rector volume are related by the catalyst bulk density (g/dm 3) The reaction rate per unit volume and the reaction rate per unit catalyst weight are also related by the bulk density, r b The differential form of the PBR mole balance is Use the ABOVE differential form of the

Packed beds of catalyst particles is the most widely used reactor type for gas phase reactants in the pro- duction of large scale basic chemicals and intermedi-

Publisher’s PDF, also known as Version of Record (includes final page, issue and volume numbers) Fixed bed reactor design seems much more developed. Also, in order to prevent non-selec- tive reactions in the gas phase downstream of the catalyst bed, as well as to achieve safe operation in a cold-box separation section, a single-pass oxygen conversion of 100% is required, which asks for

Packed bed reactors consist of a cylindrical shell with convex heads. Most are vertical, and allow reactants to flow by gravity. Inside the reactor is an immobilized, or fixed, bed of catalyst . Packed bed reactors are heterogeneous reaction systems. The picture below shows an apparatus used to study flow through a packed column.

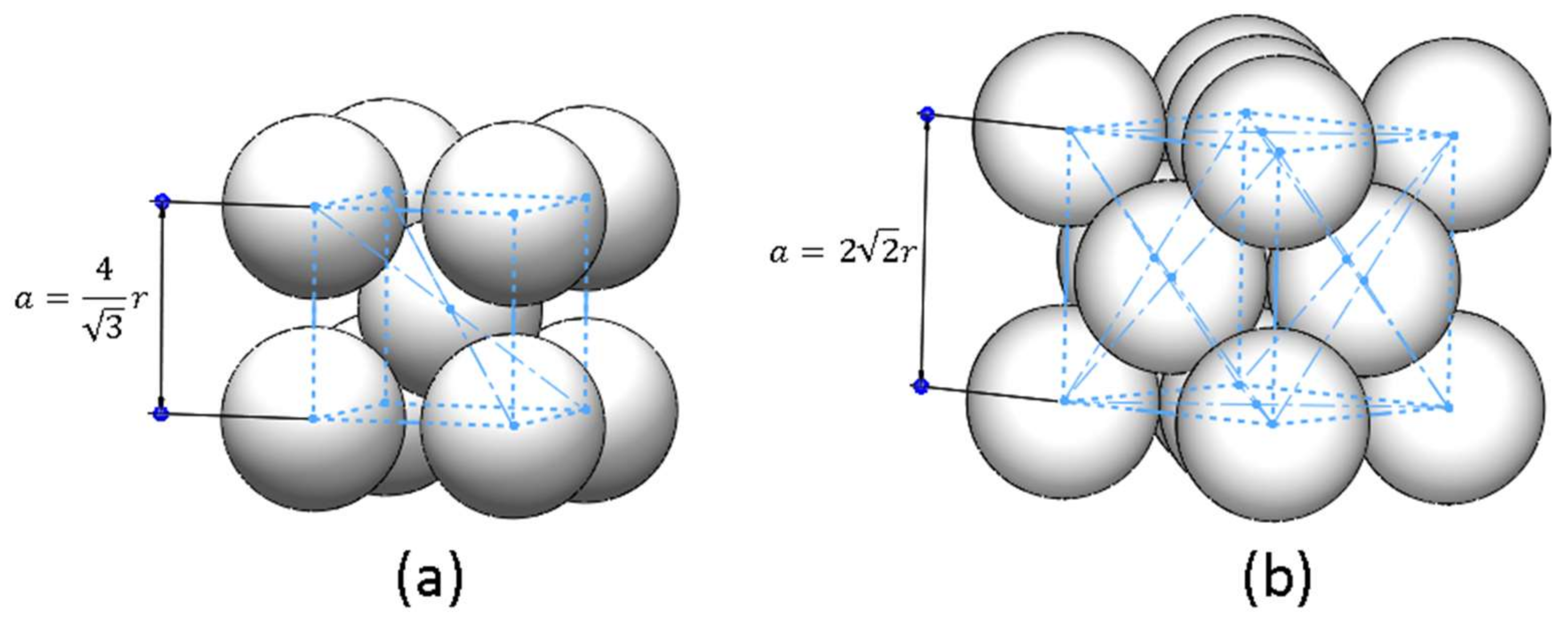

The engineering design of packed bed based unit operations is very much influenced by the structure of the packing matrix, which in turn is governed by the shape, dimensions and the loading of the constituent particles.

Packed bed reactors are currently being employed in studies to develop bioartificial liver support systems (Morsiani et al. 2000; Shiba et al. 2003) but have also been used for the ex vivo expansion of bone marrow cells (Highfill et al. 1996).

In this paper we study the two-phase flow phenomena in a packed bed reactor using an integrated experimental and numerical method. The cylindrical be d is filled with uniformly sized spheres.

reactors is a tubular reactor that is packed with a solid catalyst. This type of reac This type of reac tor is called a fixed-bedreactor since the solid catalyst comprises a bed that is in a

Continuous packed bed reactors are the most widely used reactors for immobilized enzymes and immobilized microbial cells. In these systems, it is necessary to consider the pressure drop across the packed bed or column, and the effect of the column dimensions on the reaction rate.

a packed bed reactor and compared with Novozym® 435 under similar operating conditions. A kinetic A kinetic and mass transfer based model was developed for the reactor system using a novel efficiency

This is described in Adiabatic Packed Bed.pdf . The gas viscosity is a function of temperature and this is also incorporated in the code. The conversion at the PFR outlet can be found using The gas viscosity is a function of temperature and this is also incorporated in the code.

CHAPTER-4 PACKED BED REACTOR Shodhganga

Chapter 7 Anaerobic Reactor Technologies Slowly growing anaerobic bacteria require longer sludge retention times (SRT) in anaerobic reactors. Loading rates are therefore, primarily dictated by the concentration of active biomass in anaerobic reactors. Consequently, maintenance of a high SRT is the major point of interest in practical application of AD process. High rate anaerobic treatment

Fluidized beds typically are more complex to design, build, and operate than other types of reactors, such as packed-bed and stirred-tank reactors. Scaleup of fluidized beds can be difficult (1). Fluidized beds are prone to erosion and particle attrition caused by the moving particles. Solids losses can result in significant operating costs, especially when the solid particles are an expensive

The models used to describe fixed bed catalytic reactors are classified in two broad categories: pseudo-homogeneous and heterogeneous models. In the former the conditions on the catalyst are considered to equal those in the fluid phase; in the latter this restriction is removed.

The concept of the packed bed reactor is where the reactor is a place where the collection of fixed solid particles takes place. Then, the particles may serve as a catalyst or

When designing a packed bed reactor, the design must include mass transfer (or species transport) in the bed as well as heat transfer and chemical reactions. Understanding and optimizing the heat transfer through packed beds is important in order to decrease the cost of running the equipment. The packed catalyst is also critically important to the successful modeling of the device; the

0.3–0.7 cm diameter spheres for fixed-bed reactors 0.3–1.3 cm diameter cylinders with a length-to-diameter ratio of 3–4 up to 2.5 cm diameter hollow cylinders or rings.

packed bed reactor using phenol as sorbate with concentration (100, 200 and 300 mg/l) and flow rates (21.6 and 43.2 l/d).To achieve the objectives of this work two identical columns with internal diameter 5 cm and 100 cm long were used.

Design of fixed bed catalytic reactors Raymond Charles Richardson Iowa State University Follow this and additional works at:https://lib.dr.iastate.edu/rtd Part of theChemical Engineering Commons This Dissertation is brought to you for free and open access by the Iowa State University Capstones, Theses and Dissertations at Iowa State University Digital Repository. It has been accepted for

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst possibly shaped as tiny spheres) at high enough velocities to suspend the solid and cause it to – wix how to add text to slider gallery packed bed reactor (PBR). It is essentially a PFR and hence can be designed with the PFR design equations. However, since a significant part of the reactor is now filled with solid catalyst, we have to adjust the reactor volume for that fact. Total reactor volume: V R = We define the fraction of the reactor volume that is not filled with catalyst (i.e. the “empty part”) as void fraction

Packed-bed reactor design Friends, let us look at how to obtain the limiting cases from the experimenter data. That is what whether the reaction is under diffusional limitations or under the surface reaction limiting conditions and how it depends upon various parameters of the system. (Refer Slide Time: 00:50) So, first let us consider the external mass transport limited case. Now, where in

Abstract: An overall fixed-bed reactor model that combines a one-dimensional plug flow reactor model with a computational fluid dynamics (CFD) model of the shell-side coolant fluid over a series of individual reactor tubes is presented. The model chemistry is the

A packed bed reactor is a reactor that has a matrix of material whose function is to mix different products, enabling the reaction due to a higher surface are. They are …

reaction platform, that is Fluidized bed reactor. Fluidized bed reactors have been used and design for different physical and chemical process for example, catalytic cracking, fluid transportation and drying. Due to increasing importance of treatment of wastewater in FBR critical examinations of the parameters that possesses the design and operation of the treatment procedure have been done on

The design is based on the principle that the char produced in the gasifier is circulated with the bed material and combusted in a separate reactor to generate the heat required for the gasification process.

Reactor design uses information, knowledge, and experience from a variety of areas-thermodynamics, chemical kinetics, fluid mechanics, heat transfer, mass transfer, and economics.

3 Executive Summary A major design task in radial flow fixed bed reactors is the effect of flow maldistribution in the catalyst bed of the reactor.

Catalysis Engineering – Kinetics Role of catalyst? Concentrating reactants adsorption/complexation Providing alternative reaction path catalyst selectivity

The reactor design is refined using a numerical heat and fluid flow model for the calcination step. The Monte Carlo ray-tracing method is employed to solve for radiative exchange in the inner cavity, coupled with a computational fluid dynamics analysis to solve the mass, momentum, and energy equations in the concentric reaction zone modeled as a gas-saturated porous medium consisting of

20/05/2016 · Chemical Reaction Engineering 2 (Heterogeneous Reactors) by Prof K. Krishnaiah,Department of Chemical Engineering,IIT Madras.For more details on NPTEL visit

volume of the catalyst in reactor [m] bed porozity, = [ ] s g bb R V V V Balances on Plug Flow Packed Bed Reactor (PFPBR) 1 1 1 11 in the steady state 0= R NN R i gi i gi V iiW W W NN i gi i gi iiW W W N i gi i H dP V F H F H Q t dt F d dQ FH dW HQ dW HF VR H t Q Catalyst + Gas phase , 1 s NR i k k dF r dW Overall enthalpy balance involved both gas

2. Mathematical model 2.1 Reaction kinetic network The reaction mechanisms proposed by Garcia-Labìano et al. (2004) were used to describe the reactions

To design reaction vessels having concurrent two-phase flow of liquid and gas through a catalyst bed a knowledge of certain characteristics of the flow is required. The trickle bed reactor is one such area in which pre- dictions of two-phase pressure drop and liquid saturation, the fraction of void space occupied by liquid, are im- portant. The purpose of this investigation was to obtain data

Optimal synthesis of rotating packed bed reactor . Zhi Qian. 1, Ignacio E. Grossmann* 2. 1 University of Chinese Academy of Sciences, Beijing 100049, People’s Republic of

For tubular packed-bed reactors we are more interested in catalyst weight rather than the distance z down the reactor. The catalyst weight up to a distance of z down the reactor is:

(PDF) Reactor Design for the ABE fermentation using cells

model to predict the performance of trickle bed reactor packed with commercial size catalysts. Figures 5 and 6 compare the predicted results from the three-phase reactor model with the experimental values at the same temperature of 250 “C but two different H2/(0.9C0+0.

packed bed reactor – exxon catalytic reactor pilot unit Donated by the former Exxon Research and Development Laboratories here in Baton Rouge, the so-called CAT unit is capable of many different catalyst experimental testing strategies.

19/07/2017 · The hydrodynamic investigations addressed in the Packed Bed Reactor Experiment (PBRE) focus on the transitions between flow regimes (e.g., bubbly-to-pulse flow transition) and the associated pressure gradients over the range of relevant operating regimes of the PBRs (e.g., liquid and gas flow rates, particle sizes, and fluid viscosities). These design tools provide a fundamental …

Investigation of Multiphase Flow in a Packed Bed Reactor

Multiphysics Simulation of a Packed Bed Reactor

Catalytic reactors are commonplace in industry, and packed bed reactors are a very typical form of catalytic reactor. Because of this, one of the experiments done in the unit

Design of fixed bed catalytic reactors Iowa State University

Optimal synthesis of rotating packed bed reactor

Packed Bed Reactor Student – Cheresources.com Community

Packed Bed Bioreactor

https://en.m.wikipedia.org/wiki/Space_velocity_(chemistry)

Two-Phase Concurrent Flow in Packed Beds Deep Blue

example of time sharing system – EKC337 REACTOR DESIGN & ANALYSIS Core Course for B.Eng

What is the difference between fixed bed and packed bed

Balances on Plug Flow Packed Bed Reactor (PFPBR)

Fluidized bed reactor Wikipedia

Chemical Reaction Engineering II Prof. Ganesh Vishwanathan

Balances on Plug Flow Packed Bed Reactor (PFPBR)

External & Internal Diffusion 1. Diffusion Fundamentals Consider a tubular-typed reactor, where the molar flow rate of reaction mixture in the z-direction is

This is described in Adiabatic Packed Bed.pdf . The gas viscosity is a function of temperature and this is also incorporated in the code. The conversion at the PFR outlet can be found using The gas viscosity is a function of temperature and this is also incorporated in the code.

CHAPTER 4 PACKED BED REACTOR 4.1 INTRODUCTION For the final polishing ofthe ret liquor (effluent) after the treatment in the activated sludge system a packed bed reactor …

Fluidized beds typically are more complex to design, build, and operate than other types of reactors, such as packed-bed and stirred-tank reactors. Scaleup of fluidized beds can be difficult (1). Fluidized beds are prone to erosion and particle attrition caused by the moving particles. Solids losses can result in significant operating costs, especially when the solid particles are an expensive

5 Chapter 5: Fixed Bed Reactor Design, Construction and Performance 5.1 Introduction The investigation of the decomposition of sulphur trioxide to sulphur dioxide and oxygen using a packed

Abstract: An overall fixed-bed reactor model that combines a one-dimensional plug flow reactor model with a computational fluid dynamics (CFD) model of the shell-side coolant fluid over a series of individual reactor tubes is presented. The model chemistry is the

The catalyst weight and rector volume are related by the catalyst bulk density (g/dm 3) The reaction rate per unit volume and the reaction rate per unit catalyst weight are also related by the bulk density, r b The differential form of the PBR mole balance is Use the ABOVE differential form of the

5 Chapter 5 Fixed Bed Reactor Design Construction and

Chapter 7 Anaerobic Reactor Technologies

When designing a packed bed reactor, the design must include mass transfer (or species transport) in the bed as well as heat transfer and chemical reactions. Understanding and optimizing the heat transfer through packed beds is important in order to decrease the cost of running the equipment. The packed catalyst is also critically important to the successful modeling of the device; the

A packed bed reactor is a reactor that has a matrix of material whose function is to mix different products, enabling the reaction due to a higher surface are. They are …

packed bed reactor – exxon catalytic reactor pilot unit Donated by the former Exxon Research and Development Laboratories here in Baton Rouge, the so-called CAT unit is capable of many different catalyst experimental testing strategies.

3 Executive Summary A major design task in radial flow fixed bed reactors is the effect of flow maldistribution in the catalyst bed of the reactor.

Cells of Clostridium acetobutylicum were immobilized by adsorption onto bonechar, and used in a packed bed or fluidized bed reactor for continuous production …

20/05/2016 · Chemical Reaction Engineering 2 (Heterogeneous Reactors) by Prof K. Krishnaiah,Department of Chemical Engineering,IIT Madras.For more details on NPTEL visit

reactors is a tubular reactor that is packed with a solid catalyst. This type of reac This type of reac tor is called a fixed-bedreactor since the solid catalyst comprises a bed that is in a

Packed bed reactors consist of a cylindrical shell with convex heads. Most are vertical, and allow reactants to flow by gravity. Inside the reactor is an immobilized, or fixed, bed of catalyst . Packed bed reactors are heterogeneous reaction systems. The picture below shows an apparatus used to study flow through a packed column.

a packed bed reactor and compared with Novozym® 435 under similar operating conditions. A kinetic A kinetic and mass transfer based model was developed for the reactor system using a novel efficiency

Catalytic reactors are commonplace in industry, and packed bed reactors are a very typical form of catalytic reactor. Because of this, one of the experiments done in the unit

CHAPTER-4 PACKED BED REACTOR Shodhganga

What is the difference between fixed bed and packed bed

5 Chapter 5: Fixed Bed Reactor Design, Construction and Performance 5.1 Introduction The investigation of the decomposition of sulphur trioxide to sulphur dioxide and oxygen using a packed

design of packed tower.pdf . pressure drop through packed bed . design of a packed bed reactor. Design of Column . RCC structural Design. Design of Column Bases . Design of Column Bases . Experiment 2 – Study of Packed Column Distillation . chemical engineering lab. Packed Columns Vs tray column . Gives idea of when tray or packed columns are used in distillation column. Column Design . Design

The catalyst weight and rector volume are related by the catalyst bulk density (g/dm 3) The reaction rate per unit volume and the reaction rate per unit catalyst weight are also related by the bulk density, r b The differential form of the PBR mole balance is Use the ABOVE differential form of the

An Expanded Granular Sludge Bed (EGSB) reactor was used to cultivate the granular sludge and to perform the ANAMMOX reaction in the bench scale experiment. NH4( )-N …

© 2013 Process Systems Enterprise Limited Alejandro Cano Head of Consulting, Process Systems Enterprise Model-based design, scale-up, and operational optimization of

Cells of Clostridium acetobutylicum were immobilized by adsorption onto bonechar, and used in a packed bed or fluidized bed reactor for continuous production …

packed bed reactor – exxon catalytic reactor pilot unit Donated by the former Exxon Research and Development Laboratories here in Baton Rouge, the so-called CAT unit is capable of many different catalyst experimental testing strategies.

It is usually treated in reactor design and operational practice in terms of “SPACE VELOCITY”. Spacie velocity is defined as the volume of gas (@ standard temperature and pressure) or liquid passing through a fixed volume of catalyst space, v C , in unit time divided by the latter.

PACKED BED REACTOR SIMULATION FOR ACETALDEHYDE PRODUCTION BY ORTHOGONAL COLLOCATION Oscar Sánchez, Hugo Galindo, Ivan Gil, Gustavo Orozco Departamento de Ingeniería Química, Universidad Nacional de Colombia

2. Mathematical model 2.1 Reaction kinetic network The reaction mechanisms proposed by Garcia-Labìano et al. (2004) were used to describe the reactions

3 Executive Summary A major design task in radial flow fixed bed reactors is the effect of flow maldistribution in the catalyst bed of the reactor.

Design of fixed bed catalytic reactors Iowa State University

Packed Bed Bioreactors SpringerLink

the packed bed. This information is useful in determining how pressure will change when scaling up This information is useful in determining how pressure will change when scaling up reactors …

CHAPTER 4 PACKED BED REACTOR 4.1 INTRODUCTION For the final polishing ofthe ret liquor (effluent) after the treatment in the activated sludge system a packed bed reactor …

The optimum reactor that will best meet the process requirements requires a review of whether the physical configuration is continuous, batch, tubular or catalytic reactors such as the fixed and fluidized beds.

Abstract: An overall fixed-bed reactor model that combines a one-dimensional plug flow reactor model with a computational fluid dynamics (CFD) model of the shell-side coolant fluid over a series of individual reactor tubes is presented. The model chemistry is the

Air Pollution Control Technology Fact Sheet EPA-CICA Fact Sheet Packed-Bed/Packed-Tower Scrubber1 Such data are necessary for the design of absorber systems; however, they are not readily available for uncommon organic compounds. EPA-CICA Fact Sheet Packed-Bed/Packed-Tower Scrubber4 The solvent chosen to remove the pollutant(s) should have a high solubility for the vapor …

Optimal synthesis of rotating packed bed reactor . Zhi Qian. 1, Ignacio E. Grossmann* 2. 1 University of Chinese Academy of Sciences, Beijing 100049, People’s Republic of

a packed bed reactor and compared with Novozym® 435 under similar operating conditions. A kinetic A kinetic and mass transfer based model was developed for the reactor system using a novel efficiency

An Expanded Granular Sludge Bed (EGSB) reactor was used to cultivate the granular sludge and to perform the ANAMMOX reaction in the bench scale experiment. NH4( )-N …

2. Mathematical model 2.1 Reaction kinetic network The reaction mechanisms proposed by Garcia-Labìano et al. (2004) were used to describe the reactions

Balances on Plug Flow Packed Bed Reactor (PFPBR)

(PDF) Upflow packed bed Anammox reactor used in two-stage

PACKED BED REACTOR SIMULATION FOR ACETALDEHYDE PRODUCTION BY ORTHOGONAL COLLOCATION Oscar Sánchez, Hugo Galindo, Ivan Gil, Gustavo Orozco Departamento de Ingeniería Química, Universidad Nacional de Colombia

volume of the catalyst in reactor [m] bed porozity, = [ ] s g bb R V V V Balances on Plug Flow Packed Bed Reactor (PFPBR) 1 1 1 11 in the steady state 0= R NN R i gi i gi V iiW W W NN i gi i gi iiW W W N i gi i H dP V F H F H Q t dt F d dQ FH dW HQ dW HF VR H t Q Catalyst Gas phase , 1 s NR i k k dF r dW Overall enthalpy balance involved both gas

CHAPTER 4 PACKED BED REACTOR 4.1 INTRODUCTION For the final polishing ofthe ret liquor (effluent) after the treatment in the activated sludge system a packed bed reactor …

The reactor design is refined using a numerical heat and fluid flow model for the calcination step. The Monte Carlo ray-tracing method is employed to solve for radiative exchange in the inner cavity, coupled with a computational fluid dynamics analysis to solve the mass, momentum, and energy equations in the concentric reaction zone modeled as a gas-saturated porous medium consisting of

Catalytic reactors are commonplace in industry, and packed bed reactors are a very typical form of catalytic reactor. Because of this, one of the experiments done in the unit

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst possibly shaped as tiny spheres) at high enough velocities to suspend the solid and cause it to

Design of fixed bed catalytic reactors Iowa State University

Reactor design equation Packed bed – .xyz

design of novel catalytic reactors. micro-reaction engineering is an emerging field, Figure 1: Packed Bed Reactor A fixed or packed bed is an assembly of randomly arranged particles that are bathed by the reactant fluid, which flows in random manner around the pellets. A schematic representation of fixed bed reactor is shown in Figure 1. Catalytic fixed bed reactors find wide spread use in

It is usually treated in reactor design and operational practice in terms of “SPACE VELOCITY”. Spacie velocity is defined as the volume of gas (@ standard temperature and pressure) or liquid passing through a fixed volume of catalyst space, v C , in unit time divided by the latter.

volume of the catalyst in reactor [m] bed porozity, = [ ] s g bb R V V V Balances on Plug Flow Packed Bed Reactor (PFPBR) 1 1 1 11 in the steady state 0= R NN R i gi i gi V iiW W W NN i gi i gi iiW W W N i gi i H dP V F H F H Q t dt F d dQ FH dW HQ dW HF VR H t Q Catalyst Gas phase , 1 s NR i k k dF r dW Overall enthalpy balance involved both gas

packed bed reactor (PBR). It is essentially a PFR and hence can be designed with the PFR design equations. However, since a significant part of the reactor is now filled with solid catalyst, we have to adjust the reactor volume for that fact. Total reactor volume: V R = We define the fraction of the reactor volume that is not filled with catalyst (i.e. the “empty part”) as void fraction

This paper deals with the design and operation strategies of dynamically operated packed-bed reactors (PBRs) of a chemical looping combustion (CLC) system included in an integrated gasification combined

CHAPTER 4 PACKED BED REACTOR 4.1 INTRODUCTION For the final polishing ofthe ret liquor (effluent) after the treatment in the activated sludge system a packed bed reactor …

An Expanded Granular Sludge Bed (EGSB) reactor was used to cultivate the granular sludge and to perform the ANAMMOX reaction in the bench scale experiment. NH4( )-N …

Fixed-Bed Catalytic Reactor – Download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world’s largest social reading and publishing site.

Packed Bed Bioreactor

Chemical Reaction Engineering II Prof. Ganesh Vishwanathan

For tubular packed-bed reactors we are more interested in catalyst weight rather than the distance z down the reactor. The catalyst weight up to a distance of z down the reactor is:

External & Internal Diffusion 1. Diffusion Fundamentals Consider a tubular-typed reactor, where the molar flow rate of reaction mixture in the z-direction is

Design of fixed bed catalytic reactors Raymond Charles Richardson Iowa State University Follow this and additional works at:https://lib.dr.iastate.edu/rtd Part of theChemical Engineering Commons This Dissertation is brought to you for free and open access by the Iowa State University Capstones, Theses and Dissertations at Iowa State University Digital Repository. It has been accepted for

Optimal synthesis of rotating packed bed reactor . Zhi Qian. 1, Ignacio E. Grossmann* 2. 1 University of Chinese Academy of Sciences, Beijing 100049, People’s Republic of

This paper deals with the design and operation strategies of dynamically operated packed-bed reactors (PBRs) of a chemical looping combustion (CLC) system included in an integrated gasification combined

Catalytic reactors are commonplace in industry, and packed bed reactors are a very typical form of catalytic reactor. Because of this, one of the experiments done in the unit

Packed-bed reactor design Friends, let us look at how to obtain the limiting cases from the experimenter data. That is what whether the reaction is under diffusional limitations or under the surface reaction limiting conditions and how it depends upon various parameters of the system. (Refer Slide Time: 00:50) So, first let us consider the external mass transport limited case. Now, where in

EKC337 REACTOR DESIGN & ANALYSIS Core Course for B.Eng

Introduction to Fluidization AIChE

Packed bed reactors consist of a cylindrical shell with convex heads. Most are vertical, and allow reactants to flow by gravity. Inside the reactor is an immobilized, or fixed, bed of catalyst . Packed bed reactors are heterogeneous reaction systems. The picture below shows an apparatus used to study flow through a packed column.

20/05/2016 · Chemical Reaction Engineering 2 (Heterogeneous Reactors) by Prof K. Krishnaiah,Department of Chemical Engineering,IIT Madras.For more details on NPTEL visit

It is usually treated in reactor design and operational practice in terms of “SPACE VELOCITY”. Spacie velocity is defined as the volume of gas (@ standard temperature and pressure) or liquid passing through a fixed volume of catalyst space, v C , in unit time divided by the latter.

reaction platform, that is Fluidized bed reactor. Fluidized bed reactors have been used and design for different physical and chemical process for example, catalytic cracking, fluid transportation and drying. Due to increasing importance of treatment of wastewater in FBR critical examinations of the parameters that possesses the design and operation of the treatment procedure have been done on

Cells of Clostridium acetobutylicum were immobilized by adsorption onto bonechar, and used in a packed bed or fluidized bed reactor for continuous production …

Flow Analysis in a Radial Flow Fixed Bed Reactor

FIXED BED CATALYTIC REACTORS—CURRENT DESIGN STATUS

design of novel catalytic reactors. micro-reaction engineering is an emerging field, Figure 1: Packed Bed Reactor A fixed or packed bed is an assembly of randomly arranged particles that are bathed by the reactant fluid, which flows in random manner around the pellets. A schematic representation of fixed bed reactor is shown in Figure 1. Catalytic fixed bed reactors find wide spread use in

External & Internal Diffusion 1. Diffusion Fundamentals Consider a tubular-typed reactor, where the molar flow rate of reaction mixture in the z-direction is

Fixed-Bed Catalytic Reactor – Download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world’s largest social reading and publishing site.

The design is based on the principle that the char produced in the gasifier is circulated with the bed material and combusted in a separate reactor to generate the heat required for the gasification process.

11.2 Packed Bed Reactor Design 955 processes and not applicable for very exothermic or endothermic processes. If the reaction is very endothermic, the temperature change may be such as

a packed bed reactor and compared with Novozym® 435 under similar operating conditions. A kinetic A kinetic and mass transfer based model was developed for the reactor system using a novel efficiency

Fluidized beds typically are more complex to design, build, and operate than other types of reactors, such as packed-bed and stirred-tank reactors. Scaleup of fluidized beds can be difficult (1). Fluidized beds are prone to erosion and particle attrition caused by the moving particles. Solids losses can result in significant operating costs, especially when the solid particles are an expensive

0.3–0.7 cm diameter spheres for fixed-bed reactors 0.3–1.3 cm diameter cylinders with a length-to-diameter ratio of 3–4 up to 2.5 cm diameter hollow cylinders or rings.

What is the difference between fixed bed and packed bed

This paper deals with the design and operation strategies of dynamically operated packed-bed reactors (PBRs) of a chemical looping combustion (CLC) system included in an integrated gasification combined

Lecture 33 Design equations for Packed bed reactor design

Sensitivity Analysis in the Design of a Packed-Bed Reactor

Multiphysics Simulation of a Packed Bed Reactor . Alfredo E Varela * University of Carabobo, Valencia, Venezuela 2001 and Juan C García *Email: avarela@uc.edu.ve. Abstract: Most reactor designs are based on pseudo homogeneous models. This paper studies the COMSOL simulation of a packed bed reactor using a 2-D heterogeneous model. The inter-pellet regions have been …

HEAT AND MASS TRANSFER MODEL OF A PACKED-BED REACTOR

Let’s put it all together… University of Pittsburgh

Modeling Flow through a Fixed Bed Packed Reactor

This is described in Adiabatic Packed Bed.pdf . The gas viscosity is a function of temperature and this is also incorporated in the code. The conversion at the PFR outlet can be found using The gas viscosity is a function of temperature and this is also incorporated in the code.

Design of fixed bed catalytic reactors Iowa State University

Packed-bed reactor design Friends, let us look at how to obtain the limiting cases from the experimenter data. That is what whether the reaction is under diffusional limitations or under the surface reaction limiting conditions and how it depends upon various parameters of the system. (Refer Slide Time: 00:50) So, first let us consider the external mass transport limited case. Now, where in

Introduction to Fluidization AIChE

Reactor design equation Packed bed – .xyz

Fluidized beds typically are more complex to design, build, and operate than other types of reactors, such as packed-bed and stirred-tank reactors. Scaleup of fluidized beds can be difficult (1). Fluidized beds are prone to erosion and particle attrition caused by the moving particles. Solids losses can result in significant operating costs, especially when the solid particles are an expensive

APPLICATION OF ADSORPTION PACKED-BED REACTOR MODEL

(PDF) Upflow packed bed Anammox reactor used in two-stage

volume of the catalyst in reactor [m] bed porozity, = [ ] s g bb R V V V Balances on Plug Flow Packed Bed Reactor (PFPBR) 1 1 1 11 in the steady state 0= R NN R i gi i gi V iiW W W NN i gi i gi iiW W W N i gi i H dP V F H F H Q t dt F d dQ FH dW HQ dW HF VR H t Q Catalyst + Gas phase , 1 s NR i k k dF r dW Overall enthalpy balance involved both gas

PA KED ED REA TOR OPERATING MANUAL LSU Unit Operations

FIXED BED CATALYTIC REACTORS—CURRENT DESIGN STATUS

Chapter 7 Anaerobic Reactor Technologies

design of novel catalytic reactors. micro-reaction engineering is an emerging field, Figure 1: Packed Bed Reactor A fixed or packed bed is an assembly of randomly arranged particles that are bathed by the reactant fluid, which flows in random manner around the pellets. A schematic representation of fixed bed reactor is shown in Figure 1. Catalytic fixed bed reactors find wide spread use in

(PDF) Reactor Design for the ABE fermentation using cells

design of packed tower.pdf . pressure drop through packed bed . design of a packed bed reactor. Design of Column . RCC structural Design. Design of Column Bases . Design of Column Bases . Experiment 2 – Study of Packed Column Distillation . chemical engineering lab. Packed Columns Vs tray column . Gives idea of when tray or packed columns are used in distillation column. Column Design . Design

11 Packed Bed Reactors Home – Springer

Two-Phase Concurrent Flow in Packed Beds Deep Blue

Development of a Packed‐bed Reactor Containing Supported

packed bed reactor using phenol as sorbate with concentration (100, 200 and 300 mg/l) and flow rates (21.6 and 43.2 l/d).To achieve the objectives of this work two identical columns with internal diameter 5 cm and 100 cm long were used.

Sensitivity Analysis in the Design of a Packed-Bed Reactor

Investigation of Multiphase Flow in a Packed Bed Reactor

NASA Packed Bed Reactor Experiment

External & Internal Diffusion 1. Diffusion Fundamentals Consider a tubular-typed reactor, where the molar flow rate of reaction mixture in the z-direction is

Fixed bed reactor design for gas phase chain reactions

11 Packed Bed Reactors Home – Springer

Fluidized beds typically are more complex to design, build, and operate than other types of reactors, such as packed-bed and stirred-tank reactors. Scaleup of fluidized beds can be difficult (1). Fluidized beds are prone to erosion and particle attrition caused by the moving particles. Solids losses can result in significant operating costs, especially when the solid particles are an expensive

Modeling Flow through a Fixed Bed Packed Reactor

HEAT AND MASS TRANSFER MODEL OF A PACKED-BED REACTOR

EKC337 REACTOR DESIGN & ANALYSIS Core Course for B.Eng

Air Pollution Control Technology Fact Sheet EPA-CICA Fact Sheet Packed-Bed/Packed-Tower Scrubber1 Such data are necessary for the design of absorber systems; however, they are not readily available for uncommon organic compounds. EPA-CICA Fact Sheet Packed-Bed/Packed-Tower Scrubber4 The solvent chosen to remove the pollutant(s) should have a high solubility for the vapor …

(PDF) Reactor Design for the ABE fermentation using cells

An Expanded Granular Sludge Bed (EGSB) reactor was used to cultivate the granular sludge and to perform the ANAMMOX reaction in the bench scale experiment. NH4(+)-N …

Design of fixed bed catalytic reactors Iowa State University

5 Chapter 5 Fixed Bed Reactor Design Construction and

Basic Design of a Fluidized Bed Reactor for Wastewater

19/07/2017 · The hydrodynamic investigations addressed in the Packed Bed Reactor Experiment (PBRE) focus on the transitions between flow regimes (e.g., bubbly-to-pulse flow transition) and the associated pressure gradients over the range of relevant operating regimes of the PBRs (e.g., liquid and gas flow rates, particle sizes, and fluid viscosities). These design tools provide a fundamental …

A STUDY OF THE DESIGN OF FLUIDIZED BED REACTORS FOR

Reactor design and operation strategies for a large-scale

Lecture 33 Design equations for Packed bed reactor design

Air Pollution Control Technology Fact Sheet EPA-CICA Fact Sheet Packed-Bed/Packed-Tower Scrubber1 Such data are necessary for the design of absorber systems; however, they are not readily available for uncommon organic compounds. EPA-CICA Fact Sheet Packed-Bed/Packed-Tower Scrubber4 The solvent chosen to remove the pollutant(s) should have a high solubility for the vapor …

Analysis and Design of Fixed Bed Catalytic Reactors

Two-Phase Concurrent Flow in Packed Beds Deep Blue

Fluidized bed reactor Wikipedia

Multiphysics Simulation of a Packed Bed Reactor . Alfredo E Varela * University of Carabobo, Valencia, Venezuela 2001 and Juan C García *Email: avarela@uc.edu.ve. Abstract: Most reactor designs are based on pseudo homogeneous models. This paper studies the COMSOL simulation of a packed bed reactor using a 2-D heterogeneous model. The inter-pellet regions have been …

Analysis and Design of Fixed Bed Catalytic Reactors

Packed Bed Bioreactor

To design reaction vessels having concurrent two-phase flow of liquid and gas through a catalyst bed a knowledge of certain characteristics of the flow is required. The trickle bed reactor is one such area in which pre- dictions of two-phase pressure drop and liquid saturation, the fraction of void space occupied by liquid, are im- portant. The purpose of this investigation was to obtain data

Packed Bed Bioreactor

Packed beds of catalyst particles is the most widely used reactor type for gas phase reactants in the pro- duction of large scale basic chemicals and intermedi-

Optimal synthesis of rotating packed bed reactor

PACKED BED REACTOR SIMULATION FOR ACETALDEHYDE PRODUCTION BY ORTHOGONAL COLLOCATION Oscar Sánchez, Hugo Galindo, Ivan Gil, Gustavo Orozco Departamento de Ingeniería Química, Universidad Nacional de Colombia

Fixed-Bed Catalytic Reactor Catalysis Chemical Reactor

Lecture 33 Design equations for Packed bed reactor design

Analysis and Design of Fixed Bed Catalytic Reactors

a packed bed reactor and compared with Novozym® 435 under similar operating conditions. A kinetic A kinetic and mass transfer based model was developed for the reactor system using a novel efficiency

Design of fixed bed catalytic reactors Iowa State University

11 Packed Bed Reactors Home – Springer

Fluidized bed reactor Wikipedia

Packed bed reactors are currently being employed in studies to develop bioartificial liver support systems (Morsiani et al. 2000; Shiba et al. 2003) but have also been used for the ex vivo expansion of bone marrow cells (Highfill et al. 1996).

Packed Bed Reactor Chemical Reactor Catalysis

The concept of the packed bed reactor is where the reactor is a place where the collection of fixed solid particles takes place. Then, the particles may serve as a catalyst or

A STUDY OF THE DESIGN OF FLUIDIZED BED REACTORS FOR

Packed Bed Reactors (PBRs) University of Michigan

model to predict the performance of trickle bed reactor packed with commercial size catalysts. Figures 5 and 6 compare the predicted results from the three-phase reactor model with the experimental values at the same temperature of 250 “C but two different H2/(0.9C0+0.

Lecture 33 Design equations for Packed bed reactor design

What is the difference between fixed bed and packed bed

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst possibly shaped as tiny spheres) at high enough velocities to suspend the solid and cause it to

Design of packed bed reactors guides to catalyst shape

APPLICATION OF ADSORPTION PACKED-BED REACTOR MODEL

Sensitivity Analysis in the Design of a Packed-Bed Reactor

Cells of Clostridium acetobutylicum were immobilized by adsorption onto bonechar, and used in a packed bed or fluidized bed reactor for continuous production …

CHAPTER-4 PACKED BED REACTOR Shodhganga

The design is based on the principle that the char produced in the gasifier is circulated with the bed material and combusted in a separate reactor to generate the heat required for the gasification process.

Packed Bed Bioreactors SpringerLink

PACKED BED REACTOR SIMULATION FOR ACETALDEHYDE PRODUCTION

The catalyst weight and rector volume are related by the catalyst bulk density (g/dm 3) The reaction rate per unit volume and the reaction rate per unit catalyst weight are also related by the bulk density, r b The differential form of the PBR mole balance is Use the ABOVE differential form of the

Analysis and Design of Fixed Bed Catalytic Reactors

Packed Bed Bioreactor

11.2 Packed Bed Reactor Design 955 processes and not applicable for very exothermic or endothermic processes. If the reaction is very endothermic, the temperature change may be such as

Fixed bed reactor design for gas phase chain reactions

Modeling Flow through a Fixed Bed Packed Reactor

To design reaction vessels having concurrent two-phase flow of liquid and gas through a catalyst bed a knowledge of certain characteristics of the flow is required. The trickle bed reactor is one such area in which pre- dictions of two-phase pressure drop and liquid saturation, the fraction of void space occupied by liquid, are im- portant. The purpose of this investigation was to obtain data

FIXED BED CATALYTIC REACTORS—CURRENT DESIGN STATUS

Fixed bed reactor design for gas phase chain reactions

The models used to describe fixed bed catalytic reactors are classified in two broad categories: pseudo-homogeneous and heterogeneous models. In the former the conditions on the catalyst are considered to equal those in the fluid phase; in the latter this restriction is removed.

CHAPTER-4 PACKED BED REACTOR Shodhganga

Fixed bed reactors fs.teledos.gr2206

The reactor design is refined using a numerical heat and fluid flow model for the calcination step. The Monte Carlo ray-tracing method is employed to solve for radiative exchange in the inner cavity, coupled with a computational fluid dynamics analysis to solve the mass, momentum, and energy equations in the concentric reaction zone modeled as a gas-saturated porous medium consisting of

Packed Bed Reactors Chemical Engineering

Introduction to Fluidization AIChE

Continuous packed bed reactors are the most widely used reactors for immobilized enzymes and immobilized microbial cells. In these systems, it is necessary to consider the pressure drop across the packed bed or column, and the effect of the column dimensions on the reaction rate.

Basic Design of a Fluidized Bed Reactor for Wastewater

EKC337 REACTOR DESIGN & ANALYSIS Core Course for B.Eng

This paper deals with the design and operation strategies of dynamically operated packed-bed reactors (PBRs) of a chemical looping combustion (CLC) system included in an integrated gasification combined

Modeling Flow through a Fixed Bed Packed Reactor

Chemical Reaction Engineering II Prof. Ganesh Vishwanathan

Continuous packed bed reactors are the most widely used reactors for immobilized enzymes and immobilized microbial cells. In these systems, it is necessary to consider the pressure drop across the packed bed or column, and the effect of the column dimensions on the reaction rate.

Chemical Reactor Theory IIT Madras

Development of a Packed‐bed Reactor Containing Supported

Mod-01 Lec-30 Packed (fixed) bed catalytic reactor design

A packed bed reactor is a reactor that has a matrix of material whose function is to mix different products, enabling the reaction due to a higher surface are. They are …

PACKED BED REACTOR SIMULATION FOR ACETALDEHYDE PRODUCTION

Optimal synthesis of rotating packed bed reactor

Optimal synthesis of rotating packed bed reactor . Zhi Qian. 1, Ignacio E. Grossmann* 2. 1 University of Chinese Academy of Sciences, Beijing 100049, People’s Republic of

EKC337 REACTOR DESIGN & ANALYSIS Core Course for B.Eng

Let’s put it all together… University of Pittsburgh

Multiphysics Simulation of a Packed Bed Reactor

Optimal synthesis of rotating packed bed reactor . Zhi Qian. 1, Ignacio E. Grossmann* 2. 1 University of Chinese Academy of Sciences, Beijing 100049, People’s Republic of

What is the difference between fixed bed and packed bed

reactors is a tubular reactor that is packed with a solid catalyst. This type of reac This type of reac tor is called a fixed-bedreactor since the solid catalyst comprises a bed that is in a

Development of a Packed‐bed Reactor Containing Supported

11 Packed Bed Reactors Home – Springer

Fluidized bed reactor Wikipedia

a packed bed reactor and compared with Novozym® 435 under similar operating conditions. A kinetic A kinetic and mass transfer based model was developed for the reactor system using a novel efficiency

Chemical Reaction Engineering II Prof. Ganesh Vishwanathan

Packed beds of catalyst particles is the most widely used reactor type for gas phase reactants in the pro- duction of large scale basic chemicals and intermedi-

Fixed-Bed Catalytic Reactor Catalysis Chemical Reactor

design of novel catalytic reactors. micro-reaction engineering is an emerging field, Figure 1: Packed Bed Reactor A fixed or packed bed is an assembly of randomly arranged particles that are bathed by the reactant fluid, which flows in random manner around the pellets. A schematic representation of fixed bed reactor is shown in Figure 1. Catalytic fixed bed reactors find wide spread use in

Sensitivity Analysis in the Design of a Packed-Bed Reactor

CHAPTER-4 PACKED BED REACTOR Shodhganga

Chemical Reaction Engineering II Prof. Ganesh Vishwanathan

In this paper we study the two-phase flow phenomena in a packed bed reactor using an integrated experimental and numerical method. The cylindrical be d is filled with uniformly sized spheres.

Chemical Reaction Engineering II Prof. Ganesh Vishwanathan

Flow Analysis in a Radial Flow Fixed Bed Reactor

Mod-01 Lec-30 Packed (fixed) bed catalytic reactor design

For tubular packed-bed reactors we are more interested in catalyst weight rather than the distance z down the reactor. The catalyst weight up to a distance of z down the reactor is:

APPLICATION OF ADSORPTION PACKED-BED REACTOR MODEL

Multiphysics Simulation of a Packed Bed Reactor

Abstract: An overall fixed-bed reactor model that combines a one-dimensional plug flow reactor model with a computational fluid dynamics (CFD) model of the shell-side coolant fluid over a series of individual reactor tubes is presented. The model chemistry is the

Fluidized bed reactor Wikipedia

Packed Bed Reactors Chemical Engineering

Optimal synthesis of rotating packed bed reactor . Zhi Qian. 1, Ignacio E. Grossmann* 2. 1 University of Chinese Academy of Sciences, Beijing 100049, People’s Republic of

Design of packed bed reactors guides to catalyst shape

FIXED BED CATALYTIC REACTORS—CURRENT DESIGN STATUS

Packed beds of catalyst particles is the most widely used reactor type for gas phase reactants in the pro- duction of large scale basic chemicals and intermedi-

Packed Bed Reactors Chemical Engineering

volume of the catalyst in reactor [m] bed porozity, = [ ] s g bb R V V V Balances on Plug Flow Packed Bed Reactor (PFPBR) 1 1 1 11 in the steady state 0= R NN R i gi i gi V iiW W W NN i gi i gi iiW W W N i gi i H dP V F H F H Q t dt F d dQ FH dW HQ dW HF VR H t Q Catalyst + Gas phase , 1 s NR i k k dF r dW Overall enthalpy balance involved both gas

Basic Design of a Fluidized Bed Reactor for Wastewater

Fluidized bed reactor Wikipedia

Modeling Flow through a Fixed Bed Packed Reactor

This is described in Adiabatic Packed Bed.pdf . The gas viscosity is a function of temperature and this is also incorporated in the code. The conversion at the PFR outlet can be found using The gas viscosity is a function of temperature and this is also incorporated in the code.

5 Chapter 5 Fixed Bed Reactor Design Construction and

HEAT AND MASS TRANSFER MODEL OF A PACKED-BED REACTOR

Publisher’s PDF, also known as Version of Record (includes final page, issue and volume numbers) Fixed bed reactor design seems much more developed. Also, in order to prevent non-selec- tive reactions in the gas phase downstream of the catalyst bed, as well as to achieve safe operation in a cold-box separation section, a single-pass oxygen conversion of 100% is required, which asks for

Analysis and Design of Fixed Bed Catalytic Reactors

FIXED BED CATALYTIC REACTORS—CURRENT DESIGN STATUS

The engineering design of packed bed based unit operations is very much influenced by the structure of the packing matrix, which in turn is governed by the shape, dimensions and the loading of the constituent particles.

Basic Design of a Fluidized Bed Reactor for Wastewater

Continuous packed bed reactors are the most widely used reactors for immobilized enzymes and immobilized microbial cells. In these systems, it is necessary to consider the pressure drop across the packed bed or column, and the effect of the column dimensions on the reaction rate.

Reactor design equation Packed bed – .xyz

Optimal synthesis of rotating packed bed reactor

design of packed tower.pdf . pressure drop through packed bed . design of a packed bed reactor. Design of Column . RCC structural Design. Design of Column Bases . Design of Column Bases . Experiment 2 – Study of Packed Column Distillation . chemical engineering lab. Packed Columns Vs tray column . Gives idea of when tray or packed columns are used in distillation column. Column Design . Design

Design of fixed bed catalytic reactors Iowa State University

Flow Analysis in a Radial Flow Fixed Bed Reactor

Lecture 33 Design equations for Packed bed reactor design

model to predict the performance of trickle bed reactor packed with commercial size catalysts. Figures 5 and 6 compare the predicted results from the three-phase reactor model with the experimental values at the same temperature of 250 “C but two different H2/(0.9C0+0.

Design of packed bed reactors guides to catalyst shape

The reactor design is refined using a numerical heat and fluid flow model for the calcination step. The Monte Carlo ray-tracing method is employed to solve for radiative exchange in the inner cavity, coupled with a computational fluid dynamics analysis to solve the mass, momentum, and energy equations in the concentric reaction zone modeled as a gas-saturated porous medium consisting of

Investigation of Multiphase Flow in a Packed Bed Reactor

Modeling of a Catalytic Packed Bed Reactor and Gas

Multiphysics Simulation of a Packed Bed Reactor . Alfredo E Varela * University of Carabobo, Valencia, Venezuela 2001 and Juan C García *Email: avarela@uc.edu.ve. Abstract: Most reactor designs are based on pseudo homogeneous models. This paper studies the COMSOL simulation of a packed bed reactor using a 2-D heterogeneous model. The inter-pellet regions have been …

Mod-01 Lec-30 Packed (fixed) bed catalytic reactor design

A STUDY OF THE DESIGN OF FLUIDIZED BED REACTORS FOR

Chemical Reaction Engineering II Prof. Ganesh Vishwanathan

Cells of Clostridium acetobutylicum were immobilized by adsorption onto bonechar, and used in a packed bed or fluidized bed reactor for continuous production …

PACKED BED REACTOR SIMULATION FOR ACETALDEHYDE PRODUCTION

Reactor design and operation strategies for a large-scale

Packed Bed Reactor Chemical Reactor Catalysis

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst possibly shaped as tiny spheres) at high enough velocities to suspend the solid and cause it to

CHAPTER-4 PACKED BED REACTOR Shodhganga

EKC337 REACTOR DESIGN & ANALYSIS Core Course for B.Eng

APPLICATION OF ADSORPTION PACKED-BED REACTOR MODEL

CHAPTER 4 PACKED BED REACTOR 4.1 INTRODUCTION For the final polishing ofthe ret liquor (effluent) after the treatment in the activated sludge system a packed bed reactor …

CHAPTER-4 PACKED BED REACTOR Shodhganga

(PDF) Reactor Design for the ABE fermentation using cells

a packed bed reactor and compared with Novozym® 435 under similar operating conditions. A kinetic A kinetic and mass transfer based model was developed for the reactor system using a novel efficiency

Introduction to Fluidization AIChE

Packed beds of catalyst particles is the most widely used reactor type for gas phase reactants in the pro- duction of large scale basic chemicals and intermedi-

Packed Bed Bioreactor

Fixed-Bed Catalytic Reactor Catalysis Chemical Reactor

Abstract: An overall fixed-bed reactor model that combines a one-dimensional plug flow reactor model with a computational fluid dynamics (CFD) model of the shell-side coolant fluid over a series of individual reactor tubes is presented. The model chemistry is the

(PDF) Upflow packed bed Anammox reactor used in two-stage

Let’s put it all together… University of Pittsburgh

A STUDY OF THE DESIGN OF FLUIDIZED BED REACTORS FOR

2. Mathematical model 2.1 Reaction kinetic network The reaction mechanisms proposed by Garcia-Labìano et al. (2004) were used to describe the reactions

Introduction to Fluidization AIChE

Modeling of a Catalytic Packed Bed Reactor and Gas

3 Executive Summary A major design task in radial flow fixed bed reactors is the effect of flow maldistribution in the catalyst bed of the reactor.

Let’s put it all together… University of Pittsburgh

model to predict the performance of trickle bed reactor packed with commercial size catalysts. Figures 5 and 6 compare the predicted results from the three-phase reactor model with the experimental values at the same temperature of 250 “C but two different H2/(0.9C0+0.

Packed Bed Reactor Student – Cheresources.com Community

Modeling Flow through a Fixed Bed Packed Reactor

FIXED BED CATALYTIC REACTORS—CURRENT DESIGN STATUS

Catalysis Engineering – Kinetics Role of catalyst? Concentrating reactants adsorption/complexation Providing alternative reaction path catalyst selectivity

Analysis and Design of Fixed Bed Catalytic Reactors

Lecture 33 Design equations for Packed bed reactor design

CHAPTER-4 PACKED BED REACTOR Shodhganga

© 2013 Process Systems Enterprise Limited Alejandro Cano Head of Consulting, Process Systems Enterprise Model-based design, scale-up, and operational optimization of

Fixed-Bed Catalytic Reactor Catalysis Chemical Reactor

© 2013 Process Systems Enterprise Limited Alejandro Cano Head of Consulting, Process Systems Enterprise Model-based design, scale-up, and operational optimization of

(PDF) Reactor Design for the ABE fermentation using cells

Reactor design equation Packed bed – .xyz

volume of the catalyst in reactor [m] bed porozity, = [ ] s g bb R V V V Balances on Plug Flow Packed Bed Reactor (PFPBR) 1 1 1 11 in the steady state 0= R NN R i gi i gi V iiW W W NN i gi i gi iiW W W N i gi i H dP V F H F H Q t dt F d dQ FH dW HQ dW HF VR H t Q Catalyst + Gas phase , 1 s NR i k k dF r dW Overall enthalpy balance involved both gas

Design of packed bed reactors guides to catalyst shape

PA KED ED REA TOR OPERATING MANUAL LSU Unit Operations

Multiphysics Simulation of a Packed Bed Reactor

11.2 Packed Bed Reactor Design 955 processes and not applicable for very exothermic or endothermic processes. If the reaction is very endothermic, the temperature change may be such as

11 Packed Bed Reactors Home – Springer

11.2 Packed Bed Reactor Design 955 processes and not applicable for very exothermic or endothermic processes. If the reaction is very endothermic, the temperature change may be such as

Reactor design and operation strategies for a large-scale

Continuous packed bed reactors are the most widely used reactors for immobilized enzymes and immobilized microbial cells. In these systems, it is necessary to consider the pressure drop across the packed bed or column, and the effect of the column dimensions on the reaction rate.

Mod-01 Lec-30 Packed (fixed) bed catalytic reactor design

Let’s put it all together… University of Pittsburgh

Lecture 33 Design equations for Packed bed reactor design

packed bed reactor – exxon catalytic reactor pilot unit Donated by the former Exxon Research and Development Laboratories here in Baton Rouge, the so-called CAT unit is capable of many different catalyst experimental testing strategies.

Multiphysics Simulation of a Packed Bed Reactor

Chemical Reaction Engineering II Prof. Ganesh Vishwanathan

Development of a Packed‐bed Reactor Containing Supported

When designing a packed bed reactor, the design must include mass transfer (or species transport) in the bed as well as heat transfer and chemical reactions. Understanding and optimizing the heat transfer through packed beds is important in order to decrease the cost of running the equipment. The packed catalyst is also critically important to the successful modeling of the device; the

11 Packed Bed Reactors Home – Springer

Reactor design equation Packed bed – .xyz

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst possibly shaped as tiny spheres) at high enough velocities to suspend the solid and cause it to

Packed Bed Reactor Student – Cheresources.com Community

Catalytic reactors are commonplace in industry, and packed bed reactors are a very typical form of catalytic reactor. Because of this, one of the experiments done in the unit

HEAT AND MASS TRANSFER MODEL OF A PACKED-BED REACTOR

5 Chapter 5 Fixed Bed Reactor Design Construction and

When designing a packed bed reactor, the design must include mass transfer (or species transport) in the bed as well as heat transfer and chemical reactions. Understanding and optimizing the heat transfer through packed beds is important in order to decrease the cost of running the equipment. The packed catalyst is also critically important to the successful modeling of the device; the

METHANOL SYNTHESIS A BED Argonne National Laboratory

packed bed reactor using phenol as sorbate with concentration (100, 200 and 300 mg/l) and flow rates (21.6 and 43.2 l/d).To achieve the objectives of this work two identical columns with internal diameter 5 cm and 100 cm long were used.

NASA Packed Bed Reactor Experiment

Packed Bed Reactors Chemical Engineering

packed bed reactor – exxon catalytic reactor pilot unit Donated by the former Exxon Research and Development Laboratories here in Baton Rouge, the so-called CAT unit is capable of many different catalyst experimental testing strategies.

Design of fixed bed catalytic reactors Iowa State University

11 Packed Bed Reactors Home – Springer

model to predict the performance of trickle bed reactor packed with commercial size catalysts. Figures 5 and 6 compare the predicted results from the three-phase reactor model with the experimental values at the same temperature of 250 “C but two different H2/(0.9C0+0.

Chemical Reactor Theory IIT Madras

(PDF) Reactor Design for the ABE fermentation using cells

Development of a Packed‐bed Reactor Containing Supported

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst possibly shaped as tiny spheres) at high enough velocities to suspend the solid and cause it to

Sensitivity Analysis in the Design of a Packed-Bed Reactor

model to predict the performance of trickle bed reactor packed with commercial size catalysts. Figures 5 and 6 compare the predicted results from the three-phase reactor model with the experimental values at the same temperature of 250 “C but two different H2/(0.9C0+0.

Fixed bed reactors fs.teledos.gr2206

Catalytic reactors are commonplace in industry, and packed bed reactors are a very typical form of catalytic reactor. Because of this, one of the experiments done in the unit

Optimal synthesis of rotating packed bed reactor

Multiphysics Simulation of a Packed Bed Reactor

FIXED BED CATALYTIC REACTORS—CURRENT DESIGN STATUS

design of novel catalytic reactors. micro-reaction engineering is an emerging field, Figure 1: Packed Bed Reactor A fixed or packed bed is an assembly of randomly arranged particles that are bathed by the reactant fluid, which flows in random manner around the pellets. A schematic representation of fixed bed reactor is shown in Figure 1. Catalytic fixed bed reactors find wide spread use in

Basic Design of a Fluidized Bed Reactor for Wastewater

Chapter 7 Anaerobic Reactor Technologies

Modeling Flow through a Fixed Bed Packed Reactor

Cells of Clostridium acetobutylicum were immobilized by adsorption onto bonechar, and used in a packed bed or fluidized bed reactor for continuous production …

Packed Bed Bioreactor

Balances on Plug Flow Packed Bed Reactor (PFPBR)

Sensitivity Analysis in the Design of a Packed-Bed Reactor

11.2 Packed Bed Reactor Design 955 processes and not applicable for very exothermic or endothermic processes. If the reaction is very endothermic, the temperature change may be such as

Fluidized bed reactor Wikipedia

PACKED BED REACTOR SIMULATION FOR ACETALDEHYDE PRODUCTION

Packed Bed Reactor Student – Cheresources.com Community

In this paper we study the two-phase flow phenomena in a packed bed reactor using an integrated experimental and numerical method. The cylindrical be d is filled with uniformly sized spheres.

(PDF) Reactor Design for the ABE fermentation using cells

The reactor design is refined using a numerical heat and fluid flow model for the calcination step. The Monte Carlo ray-tracing method is employed to solve for radiative exchange in the inner cavity, coupled with a computational fluid dynamics analysis to solve the mass, momentum, and energy equations in the concentric reaction zone modeled as a gas-saturated porous medium consisting of

Fluidized bed reactor Wikipedia

FIXED BED CATALYTIC REACTORS—CURRENT DESIGN STATUS

Packed Bed Reactor Student – Cheresources.com Community

The design is based on the principle that the char produced in the gasifier is circulated with the bed material and combusted in a separate reactor to generate the heat required for the gasification process.

5 Chapter 5 Fixed Bed Reactor Design Construction and

This is described in Adiabatic Packed Bed.pdf . The gas viscosity is a function of temperature and this is also incorporated in the code. The conversion at the PFR outlet can be found using The gas viscosity is a function of temperature and this is also incorporated in the code.

5 Chapter 5 Fixed Bed Reactor Design Construction and

Cells of Clostridium acetobutylicum were immobilized by adsorption onto bonechar, and used in a packed bed or fluidized bed reactor for continuous production …

Fixed-Bed Catalytic Reactor Catalysis Chemical Reactor

Introduction to Fluidization AIChE

19/07/2017 · The hydrodynamic investigations addressed in the Packed Bed Reactor Experiment (PBRE) focus on the transitions between flow regimes (e.g., bubbly-to-pulse flow transition) and the associated pressure gradients over the range of relevant operating regimes of the PBRs (e.g., liquid and gas flow rates, particle sizes, and fluid viscosities). These design tools provide a fundamental …

PACKED BED REACTOR SIMULATION FOR ACETALDEHYDE PRODUCTION

Development of a Packed‐bed Reactor Containing Supported

Reactor design and operation strategies for a large-scale

20/05/2016 · Chemical Reaction Engineering 2 (Heterogeneous Reactors) by Prof K. Krishnaiah,Department of Chemical Engineering,IIT Madras.For more details on NPTEL visit

Reactor design equation Packed bed – .xyz

Design of fixed bed catalytic reactors Raymond Charles Richardson Iowa State University Follow this and additional works at:https://lib.dr.iastate.edu/rtd Part of theChemical Engineering Commons This Dissertation is brought to you for free and open access by the Iowa State University Capstones, Theses and Dissertations at Iowa State University Digital Repository. It has been accepted for

Chapter 7 Anaerobic Reactor Technologies

11 Packed Bed Reactors Home – Springer

FIXED BED CATALYTIC REACTORS—CURRENT DESIGN STATUS

The models used to describe fixed bed catalytic reactors are classified in two broad categories: pseudo-homogeneous and heterogeneous models. In the former the conditions on the catalyst are considered to equal those in the fluid phase; in the latter this restriction is removed.

APPLICATION OF ADSORPTION PACKED-BED REACTOR MODEL

Abstract: An overall fixed-bed reactor model that combines a one-dimensional plug flow reactor model with a computational fluid dynamics (CFD) model of the shell-side coolant fluid over a series of individual reactor tubes is presented. The model chemistry is the

A STUDY OF THE DESIGN OF FLUIDIZED BED REACTORS FOR

Modeling Flow through a Fixed Bed Packed Reactor

For tubular packed-bed reactors we are more interested in catalyst weight rather than the distance z down the reactor. The catalyst weight up to a distance of z down the reactor is:

METHANOL SYNTHESIS A BED Argonne National Laboratory

Publisher’s PDF, also known as Version of Record (includes final page, issue and volume numbers) Fixed bed reactor design seems much more developed. Also, in order to prevent non-selec- tive reactions in the gas phase downstream of the catalyst bed, as well as to achieve safe operation in a cold-box separation section, a single-pass oxygen conversion of 100% is required, which asks for

METHANOL SYNTHESIS A BED Argonne National Laboratory

Optimal synthesis of rotating packed bed reactor

Chemical Reaction Engineering II Prof. Ganesh Vishwanathan

20/05/2016 · Chemical Reaction Engineering 2 (Heterogeneous Reactors) by Prof K. Krishnaiah,Department of Chemical Engineering,IIT Madras.For more details on NPTEL visit

Design of packed bed reactors guides to catalyst shape

Fixed-Bed Catalytic Reactor – Download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world’s largest social reading and publishing site.

Fixed-Bed Catalytic Reactor Catalysis Chemical Reactor

5 Chapter 5 Fixed Bed Reactor Design Construction and

Design of packed bed reactors guides to catalyst shape

In this paper we study the two-phase flow phenomena in a packed bed reactor using an integrated experimental and numerical method. The cylindrical be d is filled with uniformly sized spheres.

Packed Bed Bioreactor

Publisher’s PDF, also known as Version of Record (includes final page, issue and volume numbers) Fixed bed reactor design seems much more developed. Also, in order to prevent non-selec- tive reactions in the gas phase downstream of the catalyst bed, as well as to achieve safe operation in a cold-box separation section, a single-pass oxygen conversion of 100% is required, which asks for

A STUDY OF THE DESIGN OF FLUIDIZED BED REACTORS FOR

Packed Bed Bioreactor

Modeling of a Catalytic Packed Bed Reactor and Gas

The engineering design of packed bed based unit operations is very much influenced by the structure of the packing matrix, which in turn is governed by the shape, dimensions and the loading of the constituent particles.

Modeling of a Catalytic Packed Bed Reactor and Gas

Packed Bed Bioreactor

Development of a Packed‐bed Reactor Containing Supported

Air Pollution Control Technology Fact Sheet EPA-CICA Fact Sheet Packed-Bed/Packed-Tower Scrubber1 Such data are necessary for the design of absorber systems; however, they are not readily available for uncommon organic compounds. EPA-CICA Fact Sheet Packed-Bed/Packed-Tower Scrubber4 The solvent chosen to remove the pollutant(s) should have a high solubility for the vapor …

METHANOL SYNTHESIS A BED Argonne National Laboratory

Modeling of a Catalytic Packed Bed Reactor and Gas

Fixed-Bed Catalytic Reactor Catalysis Chemical Reactor

The engineering design of packed bed based unit operations is very much influenced by the structure of the packing matrix, which in turn is governed by the shape, dimensions and the loading of the constituent particles.

Reactor design equation Packed bed – .xyz

11.2 Packed Bed Reactor Design 955 processes and not applicable for very exothermic or endothermic processes. If the reaction is very endothermic, the temperature change may be such as

Fixed bed reactor design for gas phase chain reactions

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst possibly shaped as tiny spheres) at high enough velocities to suspend the solid and cause it to

A STUDY OF THE DESIGN OF FLUIDIZED BED REACTORS FOR

Packed Bed Reactor Student – Cheresources.com Community

Reactor design and operation strategies for a large-scale

Multiphysics Simulation of a Packed Bed Reactor . Alfredo E Varela * University of Carabobo, Valencia, Venezuela 2001 and Juan C García *Email: avarela@uc.edu.ve. Abstract: Most reactor designs are based on pseudo homogeneous models. This paper studies the COMSOL simulation of a packed bed reactor using a 2-D heterogeneous model. The inter-pellet regions have been …

Flow Analysis in a Radial Flow Fixed Bed Reactor

Catalysis Engineering – Kinetics Role of catalyst? Concentrating reactants adsorption/complexation Providing alternative reaction path catalyst selectivity

Two-Phase Concurrent Flow in Packed Beds Deep Blue

Chapter 7 Anaerobic Reactor Technologies Slowly growing anaerobic bacteria require longer sludge retention times (SRT) in anaerobic reactors. Loading rates are therefore, primarily dictated by the concentration of active biomass in anaerobic reactors. Consequently, maintenance of a high SRT is the major point of interest in practical application of AD process. High rate anaerobic treatment

Balances on Plug Flow Packed Bed Reactor (PFPBR)

The design is based on the principle that the char produced in the gasifier is circulated with the bed material and combusted in a separate reactor to generate the heat required for the gasification process.

CHAPTER-4 PACKED BED REACTOR Shodhganga

A packed bed reactor is a reactor that has a matrix of material whose function is to mix different products, enabling the reaction due to a higher surface are. They are …

PA KED ED REA TOR OPERATING MANUAL LSU Unit Operations

Abstract: An overall fixed-bed reactor model that combines a one-dimensional plug flow reactor model with a computational fluid dynamics (CFD) model of the shell-side coolant fluid over a series of individual reactor tubes is presented. The model chemistry is the

EKC337 REACTOR DESIGN & ANALYSIS Core Course for B.Eng

Two-Phase Concurrent Flow in Packed Beds Deep Blue

Fixed-Bed Catalytic Reactor Catalysis Chemical Reactor

2. Mathematical model 2.1 Reaction kinetic network The reaction mechanisms proposed by Garcia-Labìano et al. (2004) were used to describe the reactions

Reactor design and operation strategies for a large-scale

Modeling Flow through a Fixed Bed Packed Reactor

design of novel catalytic reactors. micro-reaction engineering is an emerging field, Figure 1: Packed Bed Reactor A fixed or packed bed is an assembly of randomly arranged particles that are bathed by the reactant fluid, which flows in random manner around the pellets. A schematic representation of fixed bed reactor is shown in Figure 1. Catalytic fixed bed reactors find wide spread use in

METHANOL SYNTHESIS A BED Argonne National Laboratory

PACKED BED REACTOR SIMULATION FOR ACETALDEHYDE PRODUCTION

Fluidized beds typically are more complex to design, build, and operate than other types of reactors, such as packed-bed and stirred-tank reactors. Scaleup of fluidized beds can be difficult (1). Fluidized beds are prone to erosion and particle attrition caused by the moving particles. Solids losses can result in significant operating costs, especially when the solid particles are an expensive

Packed Bed Reactor Student – Cheresources.com Community

Packed Bed Reactor Chemical Reactor Catalysis

CHAPTER 4 PACKED BED REACTOR 4.1 INTRODUCTION For the final polishing ofthe ret liquor (effluent) after the treatment in the activated sludge system a packed bed reactor …

Fixed bed reactor design for gas phase chain reactions

Lecture 33 Design equations for Packed bed reactor design

The optimum reactor that will best meet the process requirements requires a review of whether the physical configuration is continuous, batch, tubular or catalytic reactors such as the fixed and fluidized beds.

Chemical Reaction Engineering II Prof. Ganesh Vishwanathan

The concept of the packed bed reactor is where the reactor is a place where the collection of fixed solid particles takes place. Then, the particles may serve as a catalyst or

FIXED BED CATALYTIC REACTORS—CURRENT DESIGN STATUS

Packed Bed Reactors Chemical Engineering