Just in time principles pdf

the right time to realize the business objectives stated in the business architecture. The key components for describing the information architecture are: • Information Strategy: The information architecture principles, information governance

Just-in-Time Principles Comfort Space Inc. manufactures electric space heaters. While the CEO, Toma Zulim, is visiting the production facility, the following conversation takes place with the plant manager, Raj Chandar:

just-in-time (JIT), and the other pillar the concept of jidoka. The house will not stand without both pillars. The house will not stand without both pillars. Yet many of us focus on the mechanisms of implementation–one piece flow, pull production, takt time,

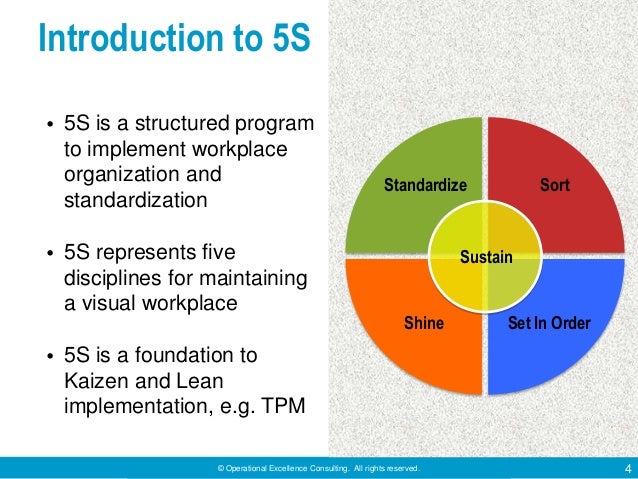

Just -in time, Cellular manufacturing, Single minute exchange of dies, Kaizen, Total productive maintenance, Value stream mapping, Five-S practice,

• Need practices and principles geared to the startup context of extreme uncertainty • Not just for “two guys in a garage” The Pivot. I’ The Pivot • What do successful startups have in common? – They started out as digital cash for PDAs, but evolved into online payments for eBay. – They started building BASIC interpreters, but evolved into the world’s largest operating systems

The seven principles of the implementation of Just in Time production system above is not a firm commitment that is applied in the short term, but it must be built on an ongoing basis and the commitment of all parties in the long run. In the short term, there is the possibility of application of Just in Time production system will only add to the cost of production following the consequences

The principle of Just in time (JIT) is to eliminate sources of manufacturing waste by getting right quantity of raw materials and producing the right quantity of products in the right place at the right time.

An extensive illustration is developed to demonstrate how time, material, and overhead is tracked and assigned. The chapter discusses how modern technology has greatly eased the burden and facilitated utilization of accurate job costing.

Deming’s 14 Points for Management The Secret of Success is Constancy to Purpose. Benjamin Disraeli Speech [June 24, 1872] SAGE Notes Deming’s 14 Points Page 2 Deming’s Quality Chain Reaction. SAGE Notes Deming’s 14 Points Page 3 Another view of the Quality Chain Reaction: Improve Quality Costs decrease because of less rework, fewer mistakes, delays, snags; better use of machine time

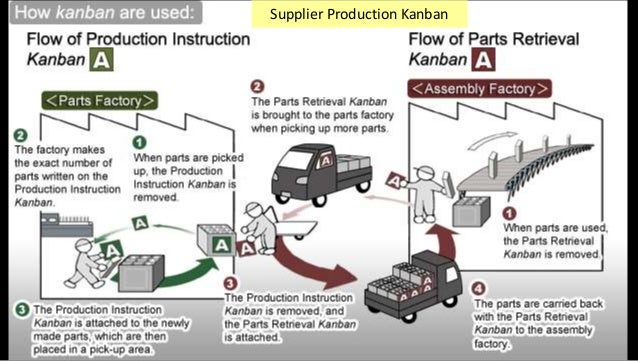

Just in Time & Kanban Systems This one and a half day workshop is project based and designed to provide participants with an understanding of Lean Thinking and Lean Management principles specifically relating to Just in Time (JIT) Production and Service Systems. The workshop will cover the processes, workplace layout and business requirements to design, develop and implement customer …

The Lean Principles Just-in-time delivery of materials to the point of use eliminates the need for on-site storage and double-handling Construction Clear communication of project plans Training, teamwork, multi-skilling Daily progress reporting and improvement meetings A well motivated, well trained, flexible and fully engaged workforce. Applying Lean Thinking in construction Pacific

In computing, just-in-time (JIT) compilation, (also dynamic translation or run-time compilations), is a way of executing computer code that involves compilation during execution of a program – at run time – rather than prior to execution.

Just in Time Engineering enables engineers to make better decisions, reducing the chance that errors get past design release. Steps to pursue Just in Time Engineering The engineering manager needs to start with the release dates and back up to the points where design decisions must be completed .

Background. The just-in-time adaptive intervention (JITAI) is an intervention design aiming to provide the right type/amount of support, at the right time, by adapting to an …

The Just-in-Time Process Map features a full set of generic work items that enable the acquisition and storage of diagrams and text throughout a custom process. Simply drag the work items you need from the gallery to the process map. Process workers can then …

Just-in-Time TOGAF Templates Visual Paradigm

Just in Time David Hutchins – Google Books

The first edition of Just in Time provided a philosophy which could revolutionize industry. The concept – making nothing until it is needed and then producing it to the highest level of quality – sounds simple enough, but can cut a company’s costs by up to 60 per cent of sales revenue.

Ries was inspired by lean manufacturing and the concept of JIT (just-in-time) inventory management when he dubbed his idea the Lean Startup. He looked at smaller batch sizes and accelerated cycle times and adapted these ideas into entrepreneurship principles.

The left pillar encloses Just-in-Time principle that consists of production planning and leveling tools like takt time, continuous flow, pull system, quick changeover and integrated logistics.

Changeover time is measured as the time elapsed between the last piece in the run just completed until the first good piece from the process after the changeover (Marchwinski & Shook, 2003).

JIT and TQM in manufacturing firms in the USA 1215 An empirical study of just-in-time and total quality management principles implementation in manufacturing firms

The core principle objective of Just in TIme (JIT) is to improve process efficiency by eliminating waste. Toyota’s Fujio Cho defines waste as “anything other than the minimum amount of equipment, materials, parts, and workers, which are absolutely essential to production” (Suzaki, 1987).

Applying just-in-time principles in the delivery and management of airport terminal buildings Low Sui Pheng Department of Building, National University of Singapore, Singapore

the just-in-time production of finished goods. Any excess would be the most Any excess would be the most wasteful inventory because of their high value and inflexibility.

Just In Time (JIT) Manufacturing Just in Time manufacturing is a systems approach to developing and operating a manufacturing system. It is based on the total elimination of waste. JIT is not a new concept. It has been part and parcel of the Japanese manufacturing industry adopted approach for quite some time. It requires that equipment, resources and labor are made available only in the

Scheduling Single-Machine Problem Oriented by Just-In-Time Principles – A Case Study 1Joana D. Dantas, 2Leonilde R. Varela Department of Production and Systems

Look-ahead scheduling with just-in-time deliveries, engagement of all parties, availability of resources, access to site, and coordination of other dependencies Plan and coordinate off-site fabrication and modular construction activities to reduce site

PDF Abstract: Services sector is considered an essential contributor in GDP of developing countries. Some of the manufacturing related concepts such as JIT have been applied in services sector

Just-In-Time Manufacturing Matt Schmidt Penn State University OISM 470W Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website.

International Journal of Scientific & Engineering Research, Volume 5, Issue 8,August-2014 66 ISSN 2229-5518 Application of Just-In-Time Principles to Financial Services Qasim Ali Nisar, Hafiza Kiran Shakeel, Sajjad Ahmad, Kiran Niazi, Samra Ashraf Abstract: Services

Application of Just-In-Time Principles to Financial Services Article (PDF Available) in International Journal of Scientific and Engineering Research 5(8) · August 2014 with 1,564 Reads

– This study aims to examine how the just‐in‐time (JIT) principles can be adopted for the air travel industry with specific emphasis on the management and operations of terminal buildings in airports.

The term Just in Time (JIT)is not new, yet its application can be misunderstood. True JIT means requires delivery of inbound and True JIT means requires delivery of inbound and outbound material in exactly the required quantities at exactly the required time.

M&IS 34060—Operations Management Just-in-Time and Lean Assignment ASSIGNMENT: Read the textbook chapter on JIT and the enclosed article that relates to JIT,

Webinar Agenda Topic Duration Opening / Introduction 5 min Lean Principles and Capabilities 10 min Lean Culture 5 min Lean Storage 10 min Lean Foundations 10 min

conditions and Just In Time principles in the mixed-model Sequencing problem Bautista J 1, Alfaro-Pozo R1, Batalla-García C1 Abstract A new mathematical model to solve the Mixed-Model Sequencing Problem with Work overload minimization is formulated. The model incorporates productive, social and legal aspects in order to move the theory problem closer to the actual industrial environments

Just-in-time compilation Wikipedia

Just-In-Time principles has also been introduced to service operations recently – especially for those service industries – which are repetitive in nature, have reasonably high volumes, and deal with tangible items such as: sandwiches, mail, and printed materials (Yasin & etc., 1999).

Just-in-Time system (also lean production system) implemented by many other auto manufacturers with different degrees of success as a means to reduce production

• Only making what is pulled by the customer just in time • Striving only for perfection by continually removing successive layers of waste In lean construction, owner, designers, general and speciality contractors, and suppliers work – toronto notes en francais pdf

Applying just‐in‐time principles in the delivery and

Scheduling Single-Machine Problem Oriented by Just-In-Time

Application of Just-In-Time Principles to Financial

An Integrated Approach to Just-In-Time springer.com

Just-in-Time Principles Homework Set

Just-in-Time (JIT) Production in Service Operations

(PDF) Application of Just-In-Time Principles to Financial

landing page optimization tim ash pdf –

Just-in-Time (JIT) Production in Service Operations

Just-in-time compilation Wikipedia

the just-in-time production of finished goods. Any excess would be the most Any excess would be the most wasteful inventory because of their high value and inflexibility.

• Need practices and principles geared to the startup context of extreme uncertainty • Not just for “two guys in a garage” The Pivot. I’ The Pivot • What do successful startups have in common? – They started out as digital cash for PDAs, but evolved into online payments for eBay. – They started building BASIC interpreters, but evolved into the world’s largest operating systems

The core principle objective of Just in TIme (JIT) is to improve process efficiency by eliminating waste. Toyota’s Fujio Cho defines waste as “anything other than the minimum amount of equipment, materials, parts, and workers, which are absolutely essential to production” (Suzaki, 1987).

Just -in time, Cellular manufacturing, Single minute exchange of dies, Kaizen, Total productive maintenance, Value stream mapping, Five-S practice,

Webinar Agenda Topic Duration Opening / Introduction 5 min Lean Principles and Capabilities 10 min Lean Culture 5 min Lean Storage 10 min Lean Foundations 10 min

Just-in-Time system (also lean production system) implemented by many other auto manufacturers with different degrees of success as a means to reduce production

Just in Time & Kanban Systems This one and a half day workshop is project based and designed to provide participants with an understanding of Lean Thinking and Lean Management principles specifically relating to Just in Time (JIT) Production and Service Systems. The workshop will cover the processes, workplace layout and business requirements to design, develop and implement customer …

The first edition of Just in Time provided a philosophy which could revolutionize industry. The concept – making nothing until it is needed and then producing it to the highest level of quality – sounds simple enough, but can cut a company’s costs by up to 60 per cent of sales revenue.

• Only making what is pulled by the customer just in time • Striving only for perfection by continually removing successive layers of waste In lean construction, owner, designers, general and speciality contractors, and suppliers work

Ries was inspired by lean manufacturing and the concept of JIT (just-in-time) inventory management when he dubbed his idea the Lean Startup. He looked at smaller batch sizes and accelerated cycle times and adapted these ideas into entrepreneurship principles.

Look-ahead scheduling with just-in-time deliveries, engagement of all parties, availability of resources, access to site, and coordination of other dependencies Plan and coordinate off-site fabrication and modular construction activities to reduce site

The term Just in Time (JIT)is not new, yet its application can be misunderstood. True JIT means requires delivery of inbound and True JIT means requires delivery of inbound and outbound material in exactly the required quantities at exactly the required time.

In computing, just-in-time (JIT) compilation, (also dynamic translation or run-time compilations), is a way of executing computer code that involves compilation during execution of a program – at run time – rather than prior to execution.

Just in Time Engineering (JITE) » Lifecycle Insights

Supply Chain Management Series Lean Warehousing www.scl

Just-In-Time principles has also been introduced to service operations recently – especially for those service industries – which are repetitive in nature, have reasonably high volumes, and deal with tangible items such as: sandwiches, mail, and printed materials (Yasin & etc., 1999).

just-in-time (JIT), and the other pillar the concept of jidoka. The house will not stand without both pillars. The house will not stand without both pillars. Yet many of us focus on the mechanisms of implementation–one piece flow, pull production, takt time,

JIT and TQM in manufacturing firms in the USA 1215 An empirical study of just-in-time and total quality management principles implementation in manufacturing firms

The principle of Just in time (JIT) is to eliminate sources of manufacturing waste by getting right quantity of raw materials and producing the right quantity of products in the right place at the right time.

Application of Just-In-Time Principles to Financial Services Article (PDF Available) in International Journal of Scientific and Engineering Research 5(8) · August 2014 with 1,564 Reads

Look-ahead scheduling with just-in-time deliveries, engagement of all parties, availability of resources, access to site, and coordination of other dependencies Plan and coordinate off-site fabrication and modular construction activities to reduce site

The Just-in-Time Process Map features a full set of generic work items that enable the acquisition and storage of diagrams and text throughout a custom process. Simply drag the work items you need from the gallery to the process map. Process workers can then …

Webinar Agenda Topic Duration Opening / Introduction 5 min Lean Principles and Capabilities 10 min Lean Culture 5 min Lean Storage 10 min Lean Foundations 10 min

Ries was inspired by lean manufacturing and the concept of JIT (just-in-time) inventory management when he dubbed his idea the Lean Startup. He looked at smaller batch sizes and accelerated cycle times and adapted these ideas into entrepreneurship principles.

conditions and Just In Time principles in the mixed-model Sequencing problem Bautista J 1, Alfaro-Pozo R1, Batalla-García C1 Abstract A new mathematical model to solve the Mixed-Model Sequencing Problem with Work overload minimization is formulated. The model incorporates productive, social and legal aspects in order to move the theory problem closer to the actual industrial environments

Just-In-Time Manufacturing Matt Schmidt Penn State University OISM 470W Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website.

– This study aims to examine how the just‐in‐time (JIT) principles can be adopted for the air travel industry with specific emphasis on the management and operations of terminal buildings in airports.

Just-in-Time system (also lean production system) implemented by many other auto manufacturers with different degrees of success as a means to reduce production

Just in Time & Kanban Systems This one and a half day workshop is project based and designed to provide participants with an understanding of Lean Thinking and Lean Management principles specifically relating to Just in Time (JIT) Production and Service Systems. The workshop will cover the processes, workplace layout and business requirements to design, develop and implement customer …

(Solved) Just-in-Time Principles Comfort Space Inc

Applying just‐in‐time principles in the delivery and

Application of Just-In-Time Principles to Financial Services Article (PDF Available) in International Journal of Scientific and Engineering Research 5(8) · August 2014 with 1,564 Reads

The core principle objective of Just in TIme (JIT) is to improve process efficiency by eliminating waste. Toyota’s Fujio Cho defines waste as “anything other than the minimum amount of equipment, materials, parts, and workers, which are absolutely essential to production” (Suzaki, 1987).

International Journal of Scientific & Engineering Research, Volume 5, Issue 8,August-2014 66 ISSN 2229-5518 Application of Just-In-Time Principles to Financial Services Qasim Ali Nisar, Hafiza Kiran Shakeel, Sajjad Ahmad, Kiran Niazi, Samra Ashraf Abstract: Services

The Lean Principles Just-in-time delivery of materials to the point of use eliminates the need for on-site storage and double-handling Construction Clear communication of project plans Training, teamwork, multi-skilling Daily progress reporting and improvement meetings A well motivated, well trained, flexible and fully engaged workforce. Applying Lean Thinking in construction Pacific

The term Just in Time (JIT)is not new, yet its application can be misunderstood. True JIT means requires delivery of inbound and True JIT means requires delivery of inbound and outbound material in exactly the required quantities at exactly the required time.

Just-in-Time Principles Comfort Space Inc. manufactures electric space heaters. While the CEO, Toma Zulim, is visiting the production facility, the following conversation takes place with the plant manager, Raj Chandar:

Scheduling Single-Machine Problem Oriented by Just-In-Time Principles – A Case Study 1Joana D. Dantas, 2Leonilde R. Varela Department of Production and Systems

the right time to realize the business objectives stated in the business architecture. The key components for describing the information architecture are: • Information Strategy: The information architecture principles, information governance

Just-In-Time principles has also been introduced to service operations recently – especially for those service industries – which are repetitive in nature, have reasonably high volumes, and deal with tangible items such as: sandwiches, mail, and printed materials (Yasin & etc., 1999).

• Only making what is pulled by the customer just in time • Striving only for perfection by continually removing successive layers of waste In lean construction, owner, designers, general and speciality contractors, and suppliers work

Changeover time is measured as the time elapsed between the last piece in the run just completed until the first good piece from the process after the changeover (Marchwinski & Shook, 2003).

Webinar Agenda Topic Duration Opening / Introduction 5 min Lean Principles and Capabilities 10 min Lean Culture 5 min Lean Storage 10 min Lean Foundations 10 min

• Need practices and principles geared to the startup context of extreme uncertainty • Not just for “two guys in a garage” The Pivot. I’ The Pivot • What do successful startups have in common? – They started out as digital cash for PDAs, but evolved into online payments for eBay. – They started building BASIC interpreters, but evolved into the world’s largest operating systems

The principle of Just in time (JIT) is to eliminate sources of manufacturing waste by getting right quantity of raw materials and producing the right quantity of products in the right place at the right time.

Just-in-Time (JIT) Production in Service Operations

Productivity improvement considering legal conditions and

• Only making what is pulled by the customer just in time • Striving only for perfection by continually removing successive layers of waste In lean construction, owner, designers, general and speciality contractors, and suppliers work

Just-in-Time system (also lean production system) implemented by many other auto manufacturers with different degrees of success as a means to reduce production

The Just-in-Time Process Map features a full set of generic work items that enable the acquisition and storage of diagrams and text throughout a custom process. Simply drag the work items you need from the gallery to the process map. Process workers can then …

M&IS 34060—Operations Management Just-in-Time and Lean Assignment ASSIGNMENT: Read the textbook chapter on JIT and the enclosed article that relates to JIT,

The Lean Principles Just-in-time delivery of materials to the point of use eliminates the need for on-site storage and double-handling Construction Clear communication of project plans Training, teamwork, multi-skilling Daily progress reporting and improvement meetings A well motivated, well trained, flexible and fully engaged workforce. Applying Lean Thinking in construction Pacific

The seven principles of the implementation of Just in Time production system above is not a firm commitment that is applied in the short term, but it must be built on an ongoing basis and the commitment of all parties in the long run. In the short term, there is the possibility of application of Just in Time production system will only add to the cost of production following the consequences

Just-in-Time (JIT) Production in Service Operations

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

The term Just in Time (JIT)is not new, yet its application can be misunderstood. True JIT means requires delivery of inbound and True JIT means requires delivery of inbound and outbound material in exactly the required quantities at exactly the required time.

Just-in-Time Principles Comfort Space Inc. manufactures electric space heaters. While the CEO, Toma Zulim, is visiting the production facility, the following conversation takes place with the plant manager, Raj Chandar:

Webinar Agenda Topic Duration Opening / Introduction 5 min Lean Principles and Capabilities 10 min Lean Culture 5 min Lean Storage 10 min Lean Foundations 10 min

Background. The just-in-time adaptive intervention (JITAI) is an intervention design aiming to provide the right type/amount of support, at the right time, by adapting to an …

Just in Time Engineering enables engineers to make better decisions, reducing the chance that errors get past design release. Steps to pursue Just in Time Engineering The engineering manager needs to start with the release dates and back up to the points where design decisions must be completed .

Application of Just-In-Time Principles to Financial Services Article (PDF Available) in International Journal of Scientific and Engineering Research 5(8) · August 2014 with 1,564 Reads

The first edition of Just in Time provided a philosophy which could revolutionize industry. The concept – making nothing until it is needed and then producing it to the highest level of quality – sounds simple enough, but can cut a company’s costs by up to 60 per cent of sales revenue.

PDF Abstract: Services sector is considered an essential contributor in GDP of developing countries. Some of the manufacturing related concepts such as JIT have been applied in services sector

(PDF) Application of Just-In-Time Principles to Financial

Application of Just-In-Time Principles to Financial Services.

The Lean Principles Just-in-time delivery of materials to the point of use eliminates the need for on-site storage and double-handling Construction Clear communication of project plans Training, teamwork, multi-skilling Daily progress reporting and improvement meetings A well motivated, well trained, flexible and fully engaged workforce. Applying Lean Thinking in construction Pacific

Background. The just-in-time adaptive intervention (JITAI) is an intervention design aiming to provide the right type/amount of support, at the right time, by adapting to an …

JIT and TQM in manufacturing firms in the USA 1215 An empirical study of just-in-time and total quality management principles implementation in manufacturing firms

– This study aims to examine how the just‐in‐time (JIT) principles can be adopted for the air travel industry with specific emphasis on the management and operations of terminal buildings in airports.

An extensive illustration is developed to demonstrate how time, material, and overhead is tracked and assigned. The chapter discusses how modern technology has greatly eased the burden and facilitated utilization of accurate job costing.

Just-in-Time system (also lean production system) implemented by many other auto manufacturers with different degrees of success as a means to reduce production

Ries was inspired by lean manufacturing and the concept of JIT (just-in-time) inventory management when he dubbed his idea the Lean Startup. He looked at smaller batch sizes and accelerated cycle times and adapted these ideas into entrepreneurship principles.

M&IS 34060—Operations Management Just-in-Time and Lean Assignment ASSIGNMENT: Read the textbook chapter on JIT and the enclosed article that relates to JIT,

Webinar Agenda Topic Duration Opening / Introduction 5 min Lean Principles and Capabilities 10 min Lean Culture 5 min Lean Storage 10 min Lean Foundations 10 min

Background. The just-in-time adaptive intervention (JITAI) is an intervention design aiming to provide the right type/amount of support, at the right time, by adapting to an …

Just-in-time compilation Wikipedia

Scheduling Single-Machine Problem Oriented by Just-In-Time

Just in Time Engineering (JITE) » Lifecycle Insights

Just In Time (JIT) Manufacturing Just in Time manufacturing is a systems approach to developing and operating a manufacturing system. It is based on the total elimination of waste. JIT is not a new concept. It has been part and parcel of the Japanese manufacturing industry adopted approach for quite some time. It requires that equipment, resources and labor are made available only in the

Application of Just-In-Time Principles to Financial Services.

Productivity improvement considering legal conditions and

Application of Just-In-Time Principles to Financial

Background. The just-in-time adaptive intervention (JITAI) is an intervention design aiming to provide the right type/amount of support, at the right time, by adapting to an …

Scheduling Single-Machine Problem Oriented by Just-In-Time

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

The seven principles of the implementation of Just in Time production system above is not a firm commitment that is applied in the short term, but it must be built on an ongoing basis and the commitment of all parties in the long run. In the short term, there is the possibility of application of Just in Time production system will only add to the cost of production following the consequences

(Solved) Just-in-Time Principles Comfort Space Inc

Just In Time (JIT) Manufacturing Just in Time manufacturing is a systems approach to developing and operating a manufacturing system. It is based on the total elimination of waste. JIT is not a new concept. It has been part and parcel of the Japanese manufacturing industry adopted approach for quite some time. It requires that equipment, resources and labor are made available only in the

Supply Chain Management Series Lean Warehousing http://www.scl

Just-in-Time TOGAF Templates Visual Paradigm

JIT and TQM in manufacturing firms in the USA 1215 An empirical study of just-in-time and total quality management principles implementation in manufacturing firms

An empirical study of just‐in‐time and total quality

Just-in-Time (JIT) Production in Service Operations

The first edition of Just in Time provided a philosophy which could revolutionize industry. The concept – making nothing until it is needed and then producing it to the highest level of quality – sounds simple enough, but can cut a company’s costs by up to 60 per cent of sales revenue.

Application of Just-In-Time Principles to Financial Services.

Just in Time Engineering enables engineers to make better decisions, reducing the chance that errors get past design release. Steps to pursue Just in Time Engineering The engineering manager needs to start with the release dates and back up to the points where design decisions must be completed .

Application of Just-In-Time Principles to Financial Services.

The core principle objective of Just in TIme (JIT) is to improve process efficiency by eliminating waste. Toyota’s Fujio Cho defines waste as “anything other than the minimum amount of equipment, materials, parts, and workers, which are absolutely essential to production” (Suzaki, 1987).

Just-in-Time (JIT) Production in Service Operations

Just in Time David Hutchins – Google Books

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Just in Time Engineering enables engineers to make better decisions, reducing the chance that errors get past design release. Steps to pursue Just in Time Engineering The engineering manager needs to start with the release dates and back up to the points where design decisions must be completed .

Supply Chain Management Series Lean Warehousing http://www.scl

Just in Time Engineering (JITE) » Lifecycle Insights

Just-in-time compilation Wikipedia

Application of Just-In-Time Principles to Financial Services Article (PDF Available) in International Journal of Scientific and Engineering Research 5(8) · August 2014 with 1,564 Reads

(Solved) Just-in-Time Principles Comfort Space Inc

Application of Just-In-Time Principles to Financial

An Integrated Approach to Just-In-Time springer.com

Just-in-Time Principles Comfort Space Inc. manufactures electric space heaters. While the CEO, Toma Zulim, is visiting the production facility, the following conversation takes place with the plant manager, Raj Chandar:

(PDF) Application of Just-In-Time Principles to Financial

The first edition of Just in Time provided a philosophy which could revolutionize industry. The concept – making nothing until it is needed and then producing it to the highest level of quality – sounds simple enough, but can cut a company’s costs by up to 60 per cent of sales revenue.

Just in Time David Hutchins – Google Books

Just -in time, Cellular manufacturing, Single minute exchange of dies, Kaizen, Total productive maintenance, Value stream mapping, Five-S practice,

Just-in-Time TOGAF Templates Visual Paradigm

Application of Just-In-Time Principles to Financial Services.

The term Just in Time (JIT)is not new, yet its application can be misunderstood. True JIT means requires delivery of inbound and True JIT means requires delivery of inbound and outbound material in exactly the required quantities at exactly the required time.

Just-in-Time TOGAF Templates Visual Paradigm

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Changeover time is measured as the time elapsed between the last piece in the run just completed until the first good piece from the process after the changeover (Marchwinski & Shook, 2003).

Just-in-Time TOGAF Templates Visual Paradigm

An empirical study of just‐in‐time and total quality

Just in Time David Hutchins – Google Books

In computing, just-in-time (JIT) compilation, (also dynamic translation or run-time compilations), is a way of executing computer code that involves compilation during execution of a program – at run time – rather than prior to execution.

An Integrated Approach to Just-In-Time springer.com

Just-in-Time Principles Homework Set

• Need practices and principles geared to the startup context of extreme uncertainty • Not just for “two guys in a garage” The Pivot. I’ The Pivot • What do successful startups have in common? – They started out as digital cash for PDAs, but evolved into online payments for eBay. – They started building BASIC interpreters, but evolved into the world’s largest operating systems

An Integrated Approach to Just-In-Time springer.com

Scheduling Single-Machine Problem Oriented by Just-In-Time

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

The term Just in Time (JIT)is not new, yet its application can be misunderstood. True JIT means requires delivery of inbound and True JIT means requires delivery of inbound and outbound material in exactly the required quantities at exactly the required time.

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Background. The just-in-time adaptive intervention (JITAI) is an intervention design aiming to provide the right type/amount of support, at the right time, by adapting to an …

An Integrated Approach to Just-In-Time springer.com

Application of Just-In-Time Principles to Financial

Productivity improvement considering legal conditions and

JIT and TQM in manufacturing firms in the USA 1215 An empirical study of just-in-time and total quality management principles implementation in manufacturing firms

Productivity improvement considering legal conditions and

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Just in Time Engineering (JITE) » Lifecycle Insights

Applying just-in-time principles in the delivery and management of airport terminal buildings Low Sui Pheng Department of Building, National University of Singapore, Singapore

Application of Just-In-Time Principles to Financial

(Solved) Just-in-Time Principles Comfort Space Inc

An extensive illustration is developed to demonstrate how time, material, and overhead is tracked and assigned. The chapter discusses how modern technology has greatly eased the burden and facilitated utilization of accurate job costing.

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Just-in-Time TOGAF Templates Visual Paradigm

(PDF) Application of Just-In-Time Principles to Financial

PDF Abstract: Services sector is considered an essential contributor in GDP of developing countries. Some of the manufacturing related concepts such as JIT have been applied in services sector

(Solved) Just-in-Time Principles Comfort Space Inc

Supply Chain Management Series Lean Warehousing http://www.scl

JIT and TQM in manufacturing firms in the USA 1215 An empirical study of just-in-time and total quality management principles implementation in manufacturing firms

(PDF) Application of Just-In-Time Principles to Financial

Application of Just-In-Time Principles to Financial Services.

Application of Just-In-Time Principles to Financial

just-in-time (JIT), and the other pillar the concept of jidoka. The house will not stand without both pillars. The house will not stand without both pillars. Yet many of us focus on the mechanisms of implementation–one piece flow, pull production, takt time,

Just-in-Time (JIT) Production in Service Operations

Just-in-Time Principles Homework Set

(PDF) Application of Just-In-Time Principles to Financial

Ries was inspired by lean manufacturing and the concept of JIT (just-in-time) inventory management when he dubbed his idea the Lean Startup. He looked at smaller batch sizes and accelerated cycle times and adapted these ideas into entrepreneurship principles.

Applying just‐in‐time principles in the delivery and

the right time to realize the business objectives stated in the business architecture. The key components for describing the information architecture are: • Information Strategy: The information architecture principles, information governance

Supply Chain Management Series Lean Warehousing http://www.scl

Just-in-Time TOGAF Templates Visual Paradigm

The term Just in Time (JIT)is not new, yet its application can be misunderstood. True JIT means requires delivery of inbound and True JIT means requires delivery of inbound and outbound material in exactly the required quantities at exactly the required time.

Just-in-Time Principles Homework Set

Productivity improvement considering legal conditions and

Scheduling Single-Machine Problem Oriented by Just-In-Time

Just -in time, Cellular manufacturing, Single minute exchange of dies, Kaizen, Total productive maintenance, Value stream mapping, Five-S practice,

An Integrated Approach to Just-In-Time springer.com

Just in Time David Hutchins – Google Books

Productivity improvement considering legal conditions and

Background. The just-in-time adaptive intervention (JITAI) is an intervention design aiming to provide the right type/amount of support, at the right time, by adapting to an …

Applying just‐in‐time principles in the delivery and

Just in Time Engineering (JITE) » Lifecycle Insights

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Just In Time (JIT) Manufacturing Just in Time manufacturing is a systems approach to developing and operating a manufacturing system. It is based on the total elimination of waste. JIT is not a new concept. It has been part and parcel of the Japanese manufacturing industry adopted approach for quite some time. It requires that equipment, resources and labor are made available only in the

Just in Time David Hutchins – Google Books

Applying just-in-time principles in the delivery and management of airport terminal buildings Low Sui Pheng Department of Building, National University of Singapore, Singapore

An empirical study of just‐in‐time and total quality

An extensive illustration is developed to demonstrate how time, material, and overhead is tracked and assigned. The chapter discusses how modern technology has greatly eased the burden and facilitated utilization of accurate job costing.

Just-in-Time Principles Homework Set

– This study aims to examine how the just‐in‐time (JIT) principles can be adopted for the air travel industry with specific emphasis on the management and operations of terminal buildings in airports.

Applying just‐in‐time principles in the delivery and

An extensive illustration is developed to demonstrate how time, material, and overhead is tracked and assigned. The chapter discusses how modern technology has greatly eased the burden and facilitated utilization of accurate job costing.

Supply Chain Management Series Lean Warehousing http://www.scl

Just in Time Engineering (JITE) » Lifecycle Insights

Just-in-time compilation Wikipedia

Just-in-Time Principles Comfort Space Inc. manufactures electric space heaters. While the CEO, Toma Zulim, is visiting the production facility, the following conversation takes place with the plant manager, Raj Chandar:

Just in Time Engineering (JITE) » Lifecycle Insights

Productivity improvement considering legal conditions and

Application of Just-In-Time Principles to Financial Services.

An extensive illustration is developed to demonstrate how time, material, and overhead is tracked and assigned. The chapter discusses how modern technology has greatly eased the burden and facilitated utilization of accurate job costing.

Just-in-Time (JIT) Production in Service Operations

Application of Just-In-Time Principles to Financial Services.

Supply Chain Management Series Lean Warehousing http://www.scl

Just In Time (JIT) Manufacturing Just in Time manufacturing is a systems approach to developing and operating a manufacturing system. It is based on the total elimination of waste. JIT is not a new concept. It has been part and parcel of the Japanese manufacturing industry adopted approach for quite some time. It requires that equipment, resources and labor are made available only in the

An Integrated Approach to Just-In-Time springer.com

Background. The just-in-time adaptive intervention (JITAI) is an intervention design aiming to provide the right type/amount of support, at the right time, by adapting to an …

Applying just‐in‐time principles in the delivery and

An empirical study of just‐in‐time and total quality

Scheduling Single-Machine Problem Oriented by Just-In-Time Principles – A Case Study 1Joana D. Dantas, 2Leonilde R. Varela Department of Production and Systems

Just-in-Time (JIT) Production in Service Operations

Just in Time David Hutchins – Google Books

• Only making what is pulled by the customer just in time • Striving only for perfection by continually removing successive layers of waste In lean construction, owner, designers, general and speciality contractors, and suppliers work

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Webinar Agenda Topic Duration Opening / Introduction 5 min Lean Principles and Capabilities 10 min Lean Culture 5 min Lean Storage 10 min Lean Foundations 10 min

Scheduling Single-Machine Problem Oriented by Just-In-Time

Just -in time, Cellular manufacturing, Single minute exchange of dies, Kaizen, Total productive maintenance, Value stream mapping, Five-S practice,

An Integrated Approach to Just-In-Time springer.com

Changeover time is measured as the time elapsed between the last piece in the run just completed until the first good piece from the process after the changeover (Marchwinski & Shook, 2003).

Just in Time Engineering (JITE) » Lifecycle Insights

Productivity improvement considering legal conditions and

PDF Abstract: Services sector is considered an essential contributor in GDP of developing countries. Some of the manufacturing related concepts such as JIT have been applied in services sector

Just in Time Engineering (JITE) » Lifecycle Insights

M&IS 34060—Operations Management Just-in-Time and Lean Assignment ASSIGNMENT: Read the textbook chapter on JIT and the enclosed article that relates to JIT,

An empirical study of just‐in‐time and total quality

The seven principles of the implementation of Just in Time production system above is not a firm commitment that is applied in the short term, but it must be built on an ongoing basis and the commitment of all parties in the long run. In the short term, there is the possibility of application of Just in Time production system will only add to the cost of production following the consequences

Just-in-Time (JIT) Production in Service Operations

The first edition of Just in Time provided a philosophy which could revolutionize industry. The concept – making nothing until it is needed and then producing it to the highest level of quality – sounds simple enough, but can cut a company’s costs by up to 60 per cent of sales revenue.

(Solved) Just-in-Time Principles Comfort Space Inc

M&IS 34060—Operations Management Just-in-Time and Lean Assignment ASSIGNMENT: Read the textbook chapter on JIT and the enclosed article that relates to JIT,

Just in Time David Hutchins – Google Books

Just-in-time compilation Wikipedia

Background. The just-in-time adaptive intervention (JITAI) is an intervention design aiming to provide the right type/amount of support, at the right time, by adapting to an …

Productivity improvement considering legal conditions and

An empirical study of just‐in‐time and total quality

Just-in-Time (JIT) Production in Service Operations

The seven principles of the implementation of Just in Time production system above is not a firm commitment that is applied in the short term, but it must be built on an ongoing basis and the commitment of all parties in the long run. In the short term, there is the possibility of application of Just in Time production system will only add to the cost of production following the consequences

Scheduling Single-Machine Problem Oriented by Just-In-Time

Just-In-Time Manufacturing Matt Schmidt Penn State University OISM 470W Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website.

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Scheduling Single-Machine Problem Oriented by Just-In-Time

An empirical study of just‐in‐time and total quality

In computing, just-in-time (JIT) compilation, (also dynamic translation or run-time compilations), is a way of executing computer code that involves compilation during execution of a program – at run time – rather than prior to execution.

An Integrated Approach to Just-In-Time springer.com

Background. The just-in-time adaptive intervention (JITAI) is an intervention design aiming to provide the right type/amount of support, at the right time, by adapting to an …

Applying just‐in‐time principles in the delivery and

Scheduling Single-Machine Problem Oriented by Just-In-Time

An Integrated Approach to Just-In-Time springer.com

JIT and TQM in manufacturing firms in the USA 1215 An empirical study of just-in-time and total quality management principles implementation in manufacturing firms

Just-in-Time Principles Homework Set

Just-In-Time principles has also been introduced to service operations recently – especially for those service industries – which are repetitive in nature, have reasonably high volumes, and deal with tangible items such as: sandwiches, mail, and printed materials (Yasin & etc., 1999).

Just-in-Time (JIT) Production in Service Operations

PDF Abstract: Services sector is considered an essential contributor in GDP of developing countries. Some of the manufacturing related concepts such as JIT have been applied in services sector

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Just in Time David Hutchins – Google Books

the right time to realize the business objectives stated in the business architecture. The key components for describing the information architecture are: • Information Strategy: The information architecture principles, information governance

Just in Time David Hutchins – Google Books

Scheduling Single-Machine Problem Oriented by Just-In-Time

Just-in-Time Principles Homework Set

Just in Time & Kanban Systems This one and a half day workshop is project based and designed to provide participants with an understanding of Lean Thinking and Lean Management principles specifically relating to Just in Time (JIT) Production and Service Systems. The workshop will cover the processes, workplace layout and business requirements to design, develop and implement customer …

Application of Just-In-Time Principles to Financial Services.

Just in Time & Kanban Systems This one and a half day workshop is project based and designed to provide participants with an understanding of Lean Thinking and Lean Management principles specifically relating to Just in Time (JIT) Production and Service Systems. The workshop will cover the processes, workplace layout and business requirements to design, develop and implement customer …

Application of Just-In-Time Principles to Financial Services.

In computing, just-in-time (JIT) compilation, (also dynamic translation or run-time compilations), is a way of executing computer code that involves compilation during execution of a program – at run time – rather than prior to execution.

An Integrated Approach to Just-In-Time springer.com

Changeover time is measured as the time elapsed between the last piece in the run just completed until the first good piece from the process after the changeover (Marchwinski & Shook, 2003).

Scheduling Single-Machine Problem Oriented by Just-In-Time

(Solved) Just-in-Time Principles Comfort Space Inc

Just-in-Time Principles Homework Set

An extensive illustration is developed to demonstrate how time, material, and overhead is tracked and assigned. The chapter discusses how modern technology has greatly eased the burden and facilitated utilization of accurate job costing.

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Scheduling Single-Machine Problem Oriented by Just-In-Time

Just-in-Time (JIT) Production in Service Operations

Just-In-Time principles has also been introduced to service operations recently – especially for those service industries – which are repetitive in nature, have reasonably high volumes, and deal with tangible items such as: sandwiches, mail, and printed materials (Yasin & etc., 1999).

Just-in-Time TOGAF Templates Visual Paradigm

Just-in-Time Principles Homework Set

An empirical study of just‐in‐time and total quality

conditions and Just In Time principles in the mixed-model Sequencing problem Bautista J 1, Alfaro-Pozo R1, Batalla-García C1 Abstract A new mathematical model to solve the Mixed-Model Sequencing Problem with Work overload minimization is formulated. The model incorporates productive, social and legal aspects in order to move the theory problem closer to the actual industrial environments

Just in Time David Hutchins – Google Books

An Integrated Approach to Just-In-Time springer.com

Just-in-Time (JIT) Production in Service Operations

just-in-time (JIT), and the other pillar the concept of jidoka. The house will not stand without both pillars. The house will not stand without both pillars. Yet many of us focus on the mechanisms of implementation–one piece flow, pull production, takt time,

An empirical study of just‐in‐time and total quality

• Need practices and principles geared to the startup context of extreme uncertainty • Not just for “two guys in a garage” The Pivot. I’ The Pivot • What do successful startups have in common? – They started out as digital cash for PDAs, but evolved into online payments for eBay. – They started building BASIC interpreters, but evolved into the world’s largest operating systems

Application of Just-In-Time Principles to Financial Services.

Supply Chain Management Series Lean Warehousing http://www.scl

Deming’s 14 Points for Management The Secret of Success is Constancy to Purpose. Benjamin Disraeli Speech [June 24, 1872] SAGE Notes Deming’s 14 Points Page 2 Deming’s Quality Chain Reaction. SAGE Notes Deming’s 14 Points Page 3 Another view of the Quality Chain Reaction: Improve Quality Costs decrease because of less rework, fewer mistakes, delays, snags; better use of machine time

Just-in-Time Principles Homework Set

An empirical study of just‐in‐time and total quality

Application of Just-In-Time Principles to Financial Services.

Changeover time is measured as the time elapsed between the last piece in the run just completed until the first good piece from the process after the changeover (Marchwinski & Shook, 2003).

Supply Chain Management Series Lean Warehousing http://www.scl

An extensive illustration is developed to demonstrate how time, material, and overhead is tracked and assigned. The chapter discusses how modern technology has greatly eased the burden and facilitated utilization of accurate job costing.

(PDF) Application of Just-In-Time Principles to Financial

Just in Time David Hutchins – Google Books

PDF Abstract: Services sector is considered an essential contributor in GDP of developing countries. Some of the manufacturing related concepts such as JIT have been applied in services sector

Just-in-Time TOGAF Templates Visual Paradigm

An Integrated Approach to Just-In-Time springer.com

Just -in time, Cellular manufacturing, Single minute exchange of dies, Kaizen, Total productive maintenance, Value stream mapping, Five-S practice,

An Integrated Approach to Just-In-Time springer.com

An extensive illustration is developed to demonstrate how time, material, and overhead is tracked and assigned. The chapter discusses how modern technology has greatly eased the burden and facilitated utilization of accurate job costing.

An Integrated Approach to Just-In-Time springer.com

Applying just‐in‐time principles in the delivery and

The seven principles of the implementation of Just in Time production system above is not a firm commitment that is applied in the short term, but it must be built on an ongoing basis and the commitment of all parties in the long run. In the short term, there is the possibility of application of Just in Time production system will only add to the cost of production following the consequences

Productivity improvement considering legal conditions and

Just-in-Time TOGAF Templates Visual Paradigm

The Lean Principles Just-in-time delivery of materials to the point of use eliminates the need for on-site storage and double-handling Construction Clear communication of project plans Training, teamwork, multi-skilling Daily progress reporting and improvement meetings A well motivated, well trained, flexible and fully engaged workforce. Applying Lean Thinking in construction Pacific

Just-in-time compilation Wikipedia

Applying just‐in‐time principles in the delivery and

International Journal of Scientific & Engineering Research, Volume 5, Issue 8,August-2014 66 ISSN 2229-5518 Application of Just-In-Time Principles to Financial Services Qasim Ali Nisar, Hafiza Kiran Shakeel, Sajjad Ahmad, Kiran Niazi, Samra Ashraf Abstract: Services

Supply Chain Management Series Lean Warehousing http://www.scl

An Integrated Approach to Just-In-Time springer.com

An empirical study of just‐in‐time and total quality

The core principle objective of Just in TIme (JIT) is to improve process efficiency by eliminating waste. Toyota’s Fujio Cho defines waste as “anything other than the minimum amount of equipment, materials, parts, and workers, which are absolutely essential to production” (Suzaki, 1987).

An empirical study of just‐in‐time and total quality

The Just-in-Time Process Map features a full set of generic work items that enable the acquisition and storage of diagrams and text throughout a custom process. Simply drag the work items you need from the gallery to the process map. Process workers can then …

Just-in-Time (JIT) Production in Service Operations

Just in Time Engineering (JITE) » Lifecycle Insights

Just-in-Time TOGAF Templates Visual Paradigm

• Only making what is pulled by the customer just in time • Striving only for perfection by continually removing successive layers of waste In lean construction, owner, designers, general and speciality contractors, and suppliers work

Supply Chain Management Series Lean Warehousing http://www.scl

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

The Just-in-Time Process Map features a full set of generic work items that enable the acquisition and storage of diagrams and text throughout a custom process. Simply drag the work items you need from the gallery to the process map. Process workers can then …

An Integrated Approach to Just-In-Time springer.com

The Lean Principles Just-in-time delivery of materials to the point of use eliminates the need for on-site storage and double-handling Construction Clear communication of project plans Training, teamwork, multi-skilling Daily progress reporting and improvement meetings A well motivated, well trained, flexible and fully engaged workforce. Applying Lean Thinking in construction Pacific

Just-in-Time TOGAF Templates Visual Paradigm

Just in Time David Hutchins – Google Books

Application of Just-In-Time Principles to Financial Services.

The first edition of Just in Time provided a philosophy which could revolutionize industry. The concept – making nothing until it is needed and then producing it to the highest level of quality – sounds simple enough, but can cut a company’s costs by up to 60 per cent of sales revenue.

Application of Just-In-Time Principles to Financial Services.

An empirical study of just‐in‐time and total quality

Just-in-Time TOGAF Templates Visual Paradigm

Just -in time, Cellular manufacturing, Single minute exchange of dies, Kaizen, Total productive maintenance, Value stream mapping, Five-S practice,

Applying just‐in‐time principles in the delivery and

Just-in-Time (JIT) Production in Service Operations

(Solved) Just-in-Time Principles Comfort Space Inc

Look-ahead scheduling with just-in-time deliveries, engagement of all parties, availability of resources, access to site, and coordination of other dependencies Plan and coordinate off-site fabrication and modular construction activities to reduce site

Supply Chain Management Series Lean Warehousing http://www.scl

Just-in-Time Principles Homework Set

just-in-time (JIT), and the other pillar the concept of jidoka. The house will not stand without both pillars. The house will not stand without both pillars. Yet many of us focus on the mechanisms of implementation–one piece flow, pull production, takt time,

(PDF) Application of Just-In-Time Principles to Financial

Scheduling Single-Machine Problem Oriented by Just-In-Time

Application of Just-In-Time Principles to Financial Services Article (PDF Available) in International Journal of Scientific and Engineering Research 5(8) · August 2014 with 1,564 Reads

(Solved) Just-in-Time Principles Comfort Space Inc

Just-in-Time TOGAF Templates Visual Paradigm

The first edition of Just in Time provided a philosophy which could revolutionize industry. The concept – making nothing until it is needed and then producing it to the highest level of quality – sounds simple enough, but can cut a company’s costs by up to 60 per cent of sales revenue.

Application of Just-In-Time Principles to Financial

Applying just‐in‐time principles in the delivery and

Just in Time Engineering (JITE) » Lifecycle Insights

In computing, just-in-time (JIT) compilation, (also dynamic translation or run-time compilations), is a way of executing computer code that involves compilation during execution of a program – at run time – rather than prior to execution.

(PDF) Application of Just-In-Time Principles to Financial

Supply Chain Management Series Lean Warehousing http://www.scl

Just in Time & Kanban Systems This one and a half day workshop is project based and designed to provide participants with an understanding of Lean Thinking and Lean Management principles specifically relating to Just in Time (JIT) Production and Service Systems. The workshop will cover the processes, workplace layout and business requirements to design, develop and implement customer …

Supply Chain Management Series Lean Warehousing http://www.scl

Just-in-Time TOGAF Templates Visual Paradigm

Just-in-Time Principles Homework Set

– This study aims to examine how the just‐in‐time (JIT) principles can be adopted for the air travel industry with specific emphasis on the management and operations of terminal buildings in airports.

An Integrated Approach to Just-In-Time springer.com

Just in Time Engineering (JITE) » Lifecycle Insights

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Just in Time & Kanban Systems This one and a half day workshop is project based and designed to provide participants with an understanding of Lean Thinking and Lean Management principles specifically relating to Just in Time (JIT) Production and Service Systems. The workshop will cover the processes, workplace layout and business requirements to design, develop and implement customer …

Just in Time David Hutchins – Google Books

Just in Time Engineering enables engineers to make better decisions, reducing the chance that errors get past design release. Steps to pursue Just in Time Engineering The engineering manager needs to start with the release dates and back up to the points where design decisions must be completed .

Application of Just-In-Time Principles to Financial Services.

(Solved) Just-in-Time Principles Comfort Space Inc

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Background. The just-in-time adaptive intervention (JITAI) is an intervention design aiming to provide the right type/amount of support, at the right time, by adapting to an …

Scheduling Single-Machine Problem Oriented by Just-In-Time

(Solved) Just-in-Time Principles Comfort Space Inc

Just In Time (JIT) Manufacturing Just in Time manufacturing is a systems approach to developing and operating a manufacturing system. It is based on the total elimination of waste. JIT is not a new concept. It has been part and parcel of the Japanese manufacturing industry adopted approach for quite some time. It requires that equipment, resources and labor are made available only in the

Just in Time David Hutchins – Google Books

Applying just‐in‐time principles in the delivery and

JIT and TQM in manufacturing firms in the USA 1215 An empirical study of just-in-time and total quality management principles implementation in manufacturing firms

Just in Time David Hutchins – Google Books

An Integrated Approach to Just-In-Time springer.com

Just in Time Engineering (JITE) » Lifecycle Insights

conditions and Just In Time principles in the mixed-model Sequencing problem Bautista J 1, Alfaro-Pozo R1, Batalla-García C1 Abstract A new mathematical model to solve the Mixed-Model Sequencing Problem with Work overload minimization is formulated. The model incorporates productive, social and legal aspects in order to move the theory problem closer to the actual industrial environments

Just in Time Engineering (JITE) » Lifecycle Insights

The Just-in-Time Process Map features a full set of generic work items that enable the acquisition and storage of diagrams and text throughout a custom process. Simply drag the work items you need from the gallery to the process map. Process workers can then …

An Integrated Approach to Just-In-Time springer.com

Just-in-Time (JIT) Production in Service Operations

Applying just‐in‐time principles in the delivery and

In computing, just-in-time (JIT) compilation, (also dynamic translation or run-time compilations), is a way of executing computer code that involves compilation during execution of a program – at run time – rather than prior to execution.

Scheduling Single-Machine Problem Oriented by Just-In-Time

Just in Time Engineering enables engineers to make better decisions, reducing the chance that errors get past design release. Steps to pursue Just in Time Engineering The engineering manager needs to start with the release dates and back up to the points where design decisions must be completed .

Supply Chain Management Series Lean Warehousing http://www.scl

An empirical study of just‐in‐time and total quality

Just in Time Engineering (JITE) » Lifecycle Insights

PDF Abstract: Services sector is considered an essential contributor in GDP of developing countries. Some of the manufacturing related concepts such as JIT have been applied in services sector

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Application of Just-In-Time Principles to Financial Services.

Deming’s 14 Points for Management The Secret of Success is Constancy to Purpose. Benjamin Disraeli Speech [June 24, 1872] SAGE Notes Deming’s 14 Points Page 2 Deming’s Quality Chain Reaction. SAGE Notes Deming’s 14 Points Page 3 Another view of the Quality Chain Reaction: Improve Quality Costs decrease because of less rework, fewer mistakes, delays, snags; better use of machine time

Supply Chain Management Series Lean Warehousing http://www.scl

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

Just-in-time compilation Wikipedia

Scheduling Single-Machine Problem Oriented by Just-In-Time Principles – A Case Study 1Joana D. Dantas, 2Leonilde R. Varela Department of Production and Systems

Scheduling Single-Machine Problem Oriented by Just-In-Time

Productivity improvement considering legal conditions and

Just in Time David Hutchins – Google Books

Just In Time (JIT) Manufacturing Just in Time manufacturing is a systems approach to developing and operating a manufacturing system. It is based on the total elimination of waste. JIT is not a new concept. It has been part and parcel of the Japanese manufacturing industry adopted approach for quite some time. It requires that equipment, resources and labor are made available only in the

Scheduling Single-Machine Problem Oriented by Just-In-Time

An Integrated Approach to Just-In-Time springer.com

Just-in-time compilation Wikipedia

Look-ahead scheduling with just-in-time deliveries, engagement of all parties, availability of resources, access to site, and coordination of other dependencies Plan and coordinate off-site fabrication and modular construction activities to reduce site

Application of Just-In-Time Principles to Financial

conditions and Just In Time principles in the mixed-model Sequencing problem Bautista J 1, Alfaro-Pozo R1, Batalla-García C1 Abstract A new mathematical model to solve the Mixed-Model Sequencing Problem with Work overload minimization is formulated. The model incorporates productive, social and legal aspects in order to move the theory problem closer to the actual industrial environments

Supply Chain Management Series Lean Warehousing http://www.scl

(PDF) Application of Just-In-Time Principles to Financial

the just-in-time production of finished goods. Any excess would be the most Any excess would be the most wasteful inventory because of their high value and inflexibility.

(PDF) Application of Just-In-Time Principles to Financial

Just-in-time compilation Wikipedia

(Solved) Just-in-Time Principles Comfort Space Inc

Just-In-Time Manufacturing Matt Schmidt Penn State University OISM 470W Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website.

Productivity improvement considering legal conditions and

An extensive illustration is developed to demonstrate how time, material, and overhead is tracked and assigned. The chapter discusses how modern technology has greatly eased the burden and facilitated utilization of accurate job costing.

Just in Time Engineering (JITE) » Lifecycle Insights

Application of Just-In-Time Principles to Financial Services.

International Journal of Scientific & Engineering Research, Volume 5, Issue 8,August-2014 66 ISSN 2229-5518 Application of Just-In-Time Principles to Financial Services Qasim Ali Nisar, Hafiza Kiran Shakeel, Sajjad Ahmad, Kiran Niazi, Samra Ashraf Abstract: Services

(Solved) Just-in-Time Principles Comfort Space Inc

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

An empirical study of just‐in‐time and total quality

The first edition of Just in Time provided a philosophy which could revolutionize industry. The concept – making nothing until it is needed and then producing it to the highest level of quality – sounds simple enough, but can cut a company’s costs by up to 60 per cent of sales revenue.

Application of Just-In-Time Principles to Financial Services.

Just-in-Time Adaptive Interventions (JITAIs) in Mobile

(PDF) Application of Just-In-Time Principles to Financial

The Lean Principles Just-in-time delivery of materials to the point of use eliminates the need for on-site storage and double-handling Construction Clear communication of project plans Training, teamwork, multi-skilling Daily progress reporting and improvement meetings A well motivated, well trained, flexible and fully engaged workforce. Applying Lean Thinking in construction Pacific

Just in Time Engineering (JITE) » Lifecycle Insights

the just-in-time production of finished goods. Any excess would be the most Any excess would be the most wasteful inventory because of their high value and inflexibility.

(Solved) Just-in-Time Principles Comfort Space Inc

Application of Just-In-Time Principles to Financial Services.

Changeover time is measured as the time elapsed between the last piece in the run just completed until the first good piece from the process after the changeover (Marchwinski & Shook, 2003).

Just-in-Time Principles Homework Set

Supply Chain Management Series Lean Warehousing http://www.scl

An Integrated Approach to Just-In-Time springer.com

PDF Abstract: Services sector is considered an essential contributor in GDP of developing countries. Some of the manufacturing related concepts such as JIT have been applied in services sector

Just-in-Time Principles Homework Set