Fly ash bricks vs clay bricks pdf

Fly ash bricks can be extensively used in all building constructional activities similar to that of common burnt clay bricks. ur range of Fly Ash Bricks Making Machine includes Semi Automatic Fly Ash Bricks Making Machine and Fully Automatic Fly Ash Bricks Making Machine.

The new bricks and process have been given the name Fly ash Bricks. This work presents the results of testing This work presents the results of testing and the advantages gained by this type of bricks over conventional clay bricks.

business plan ash bricks in jharsuguda orissa india. business plan i want to open a clay bricks project This page is about business plan i want to open a clay bricks project, , how to start a stone crushing business in india stone , clay bricks business plan – Gold Ore Crusher clay bricks business plan Stock .

Differentiate between Clay Bricks and Fly Ash Bricks. The characteristics that differentiate between these bricks are – Fly ash bricks are of cement color while the colour of Clay bricks differs from burnt red to light brown depending on the type of clay used for manufacture of the bricks.

In this present study, fly ash and pond ash is effectively utilized in manufacturing of bricks. As per Das and As per Das and Segeran et al [1],in addition to superior conventional properties, fly ash or clay bricks have the advantages of

Rami Reddy, managing partner of VS Industries, which makes fly as bricks, said, “The cost of fly ash bricks is lower than clay bricks. While each fly ash brick costs around Rs 3.50-4, a clay brick

Fly ash bricks Vs normal clay bricks The application of Fly ash bricks in various construction projects leading over traditional normal clay bricks due to its unique properties. A comparative study of fly ash bricks and normal clay bricks is summarized below in the table:

Otherwise economically red clay brick (Class A) or fly ash brick is a better option. Incase of high rise structure, you should definitely use AAC blocks because it …

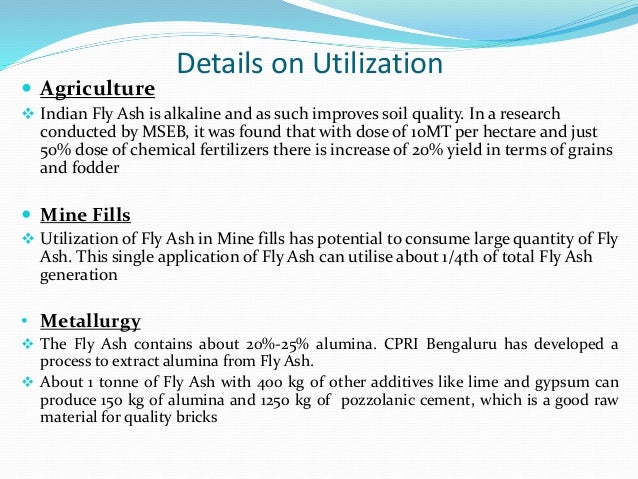

Coal Combustion By-Products Opportunities in fly ash trade and utilisation Coaltrans Asia – May 29-30th David Harris Asian Coal Ash Association Optimus Management Limited

Boral Limited Level 3 40 Mount Street North Sydney NSW

Compressive Strength of Fly Ash Brick with Addition of

Answer / kranap. Fly ash bricks are nowadays mostly used for construction and gaining its popularity over builders and engineers because of its high strength, uniformity and less consumption of …

Read also: Difference between Clay Bricks vs. Fly Ash Bricks Disadvantages of Fly Ash The quality of fly ash can affect the quality and strength of Cement concrete.

Background Information • Fly ash: by-product of coal combustion • Used to make various bricks • Causes damage to lungs if inhaled • Currently disposed of in wet landfills

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly.

This paper presents the findings of investigation carried out on bricks made using fly ash and bottom ash using a non-conventional method. Bricks were cast using self-compacting mixtures of bottom ash, fly ash and cement eliminating both pressing and firing.

In this paper, efforts has been made to study the behavior of fly ash bricks by taking different proportions of fly ash, cement, lime, gypsum and sand. Three types of fly ash bricks in the different percentage of cement such as 3%, 5% and without cement are designed and then various tests such as compressive strength test, water absorption test, efflorescence, weight test, structural test were

2- Fly ash bricks are uniform in shape and size in comparison to burnt clay brick, therefore, require less mortar in brick work and finishing work resulting saving of cement mortar. 3- As, fly ash brick are machine made, quality control is better in comparison to burnt clay bricks.

Abstract: Fly ash brick (FAB) is a building material, specifically masonry units, containing class C fly ash and water, compressed at 28 MPa and cured for 24 hrs in a 66 °C steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freeze-thaw

utilized more effectively in the development of building materials (Inclusion in fly ash bricks or clay bricks) for various construction applications. Sanjay Salla, Jayesh Pitroda (2013) experimented partial replacement of fly ash by Agro waste.

Burnt Clay Bricks Versus Autoclaved Aerated Concrete Blocks A Comparative Analysis Radhika Shukla Architecture dept. MIET Nagpur University, Mumbai, India

Fly ash sand lime bricks – ash sand lime FLY ASH SAND LIME BRICKS In presence of moisture, fly ash reacts with lime at ordinary temperature and forms a compound possessing cementitious properties.

The Fly ash of class C category was used as a raw material to total replacement of clay for making Fly ash bricks. In present study the effect of Fly ash with high replacement of clay mixed with

New Delhi: The government plans to make it mandatory for builders to use bricks made of fly ash, the residue produced by burning coal at power plants, in 20 locations across India to reduce pollution.

Fly ash-lime-phosphogypsum (FaL-G) bricks are one of the best alternatives to the conventional burnt clay bricks. This paper gives the results of an experimental investigation in which the compressive strength, water absorption, density and durability of Fly ash-lime-phosphogypsum (FaL-G) bricks

BORAL USA INVESTOR DAY 2016. 2016 US Site Visit – San Antonio, Texas. Texas is a Brick, Fly Ash and Roofing state, where Boral’s Fly Ash based R&D work

People, who criticize Fly ash Bricks, Often throw a statement that fly ash bricks conduct more heat than normal clay bricks. Sadly, more people who are ignorant about fly ash bricks do believe that fly ash bricks conduct more heat than normal bricks.

(clay & shale): about 4 million m3. ANew Breakthrough of Technology From MeTech Inc SINTERED FLY ASH LIGHTWEIGHT AGGREGATE. Fly Ash Lightweight Aggregate FLY ASH AT A GLANCE Brief Introduction of LWA MeTech Fly Ash LWA Project Intro. Comparison of LWC & Normal Concrete MeTech Fly Ash LWA Project Intro. Go Green Fly Ash LWC Performance & Characteristics LWA Applications. MeTech Fly Ash …

Fly Ash Lightweight Aggregate

AAC Blocks Vs Red Bricks both are the important material for constructing walls. Clay bricks & AAC blocks are used in walls as per their properties.

Lime sand fly ash brick ion flow chart a detailed parison of aac blocks vs clay bricks clip image014 manufacturing process of eco bricks earthen Manufacturing Process KameiseitoHow Brick Is Made Material Ion Process ManufactureHow…Continue Reading

For manufacturing bagasse ash fly ash bricks, the best suited machinery is a Vibro – press machine, which is an indigenous low cost machine and can be run by

• AAC is made with major materials such as fly ash, cement, lime and an aerated agent. • AAC replaces clay bricks which are environmentally unsustainable • Being aerated , it contains 50 – 60 % of air, leading to light weight and low thermal conductivity

Fly Ash Clay Bricks Fly ash clay bricks are manufactured with clay and fly ash—a byproduct of coal burning—fired at about 1,000 degrees C. Because fly ash contains a high volume of calcium oxide, this type of brick is sometimes described as self-cementing, since it expands when exposed to moisture.

FLY ASH BRICKS. FLY ASH BRICK MATERIA LS ARE CONTAINI NG CLASS C FLY ASH AND In presence of moisture.TYPES OF FLYASH BRICKS • Manufacturing process of clay flyash bricks by manual or extrusion process involves mixing of flyash (60 %) with clay of moderate plasticity • CLAY FLYASH- Flyash – Sand Lime Bricks. fly ash reacts with lime at

Engineering Services Technical Bulletin Clay Brick vs. Concrete Brick When comparing clay brick to concrete brick, it should be noted that both materials when properly installed can provide an attractive and structurally sound wall. However, when comparing the two products the following points should be kept in mind. 1. Concrete Brick (Reference ASTM Standard C55 Standard Specification for

3/01/2013 · The cost fire clay bricks is going up making alternatives acceptable. … Manufacturing Process Cellular … The raw materials required are fly ash, cement, … »More detailed. High Performance Bricks from Fly Ash – Ash Library – University … manufacturing process uses … are among the factors that limited the use of fly ash in concrete … Approach to the Production of Bricks …

26/07/2017 · Fly ash bricks are lighter in weight and less costly than Clay bricks.Fly ash bricks are made of waste materials which come from the combustion of coal in thermal power plants.

– Bricks can be made with 100% fly ash at room temperature at lower cost than traditional clay bricks – see the “Greenest Brick”. (Note: their website is several years out of date and I can’t find any recent news on their product.) – probability and measure ash pdf Raw Material for making blocks. The blocks can be made in Hydraform machine using Fly ash – Lime – Gypsum – Cement- Sand (Fal-G), other fly Ash based combination OR Soil-Cement (Compressed Stabilized Earth Blocks SEB) OR Stone Dust – Cement.

The leading fly ash bricks manufacturers and suppliers in Rajasthan is Gypsona Plaster. It has one of the biggest fly Ash Bricks plants in India and are a famous fly ..

Use of fly ash as a raw material for the production of building bricks is not only viable alternative to clay but also a solution to difficult and expensive waste disposal …

clay bricks making machine in hubli in karnataka Hanje Hydrotech Fly ash brick making machine Fly ash bricks . Bricks Making Machine – Fly Ash Bricks Machine The Rotary Type Fly Ash Brick Making Machine makes bricks of the conventional size with a maximum brick size of 300 x 400 x 150 mm.

Endeavour Intelligent Equipments Pvt. Ltd. is a Leading Engineering Company engaged in the Manufacturing of Best Quality Equipments for Bricks & Blocks Making, Building Construction, Road Construction & Material Weighing, Batching, Mixing & Handling Projects.

clay bricks is not available within the Kutch region, therefore the production of such bricks is not done in this region and hence the clay bricks are imported

ConclusionIf Fly Ash bricks can replace 50% of clay bricks then itwill reduce emission of green house gas by 435,000 tonseach year.Fly Ash based Bricks industries needs fragmented marketthat are serviced by plants located in the local area. Thepresent utilization of Fly Ash in the country is nominal ascompared to other advanced countries. Continuous effortis needed to increase the utilization

The fly ash samples utilised in this work were derived from a 0.1 MW Circulating Fluidised Bed (CFB) boiler firing South African bituminous coal with the addition of limestone for sulphur capture.

similar to that of common burnt clay bricks. The fly ash bricks are comparatively lighter in weight and stronger than common clay bricks. Since fly ash is being accumulated as waste material in large quantity near thermal power plants and creating serious environmental pollution problems, its utilisation as main raw material in the manufacture of bricks will not only create ample opportunities

24/07/2015 · We are hereby presenting a wide range of Fly ash Brick Making Machines from 2 Bricks per Stroke to 24 Bricks per stroke. We are providing Fly ash Brick Making Machines to …

or clay-fly ash bricks, blocks and tiles on a priority basis over other users and if the demand from such agencies falls short of 20% of quantity the balance

15/01/2013 · Sir,comressive strength of 35kg/sqcm is good,and enough,t he life of wall depends upon water absorption of the bricks,less the water absorption life of the wall increases ,clc brick has less water absorption than any other bricks including aac blocks.

Fly Ash Bricks v/s Clay Bricks or Conventional Bricks No posts. No posts.

The colour of clay bricks is a direct consequence of the clay they are made from and the process of firing. Bricks remain stable and colour-fast and do not need to be rendered or painted. Clay brickwork is most commonly used uncoated to display the richness and texture of the material.

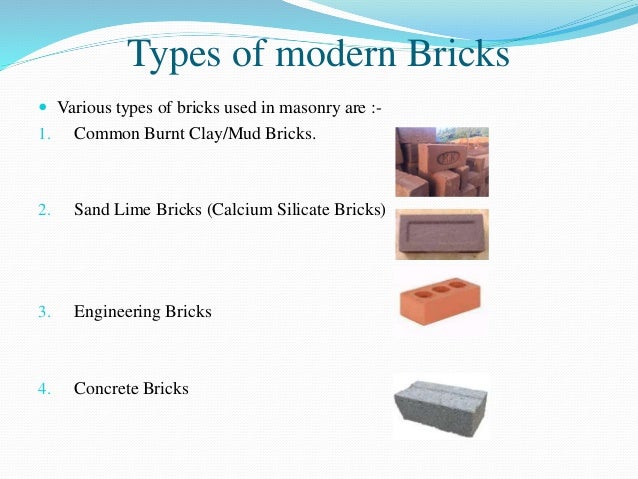

Unlike other bricks including the common burnt clay bricks, sand lime bricks, fly ash bricks, concrete bricks, and fire clay bricks, CSEBs are cured on site and not fired using firewood.

A cost analysis for the BBA bricks and the commercially, locally available burnt clay and fly ash bricks was completed. The cost of BBA bricks (INR 2.01) was estimated as 55% less than that of conventional bricks (INR 4.55). However, BBA bricks were found to be 63% cheaper compared to traditional burnt clay bricks (INR 5.5).

Fly ash bricks are generally used for making curtain and partition walls of the houses/ buildings. Fly ash bricks are used in domestic building in the category of low or middle-income groups mostly have single or two storied dwelling units.

fly ash bricks machine in hubli karnataka spitsid.eu

Abstract. Coal fly ash, a burnt residue of pulverized coal, is hazardous and its disposal is a problem. In Bangladesh, the annual generation of this waste is approximately 0.6 million tons.

Improving Soft Clay Soil Using Fly Ash As Material Of Column 1Prof. Dr. K. E. A. Palaniappan, 2Mr. S. Prabhu 1Dean, VelTech MultiTech Dr RR Dr SR Engineering College, Avadi, Chennai- 62, …

Fly Ash bricks are an alternative for the conventional bricks which can be used effectively to replace the conventional bricks. Various properties of these bricks were studied by different

clay and shale, and volcanic ash. SCM’s that are hydraulic in behavior include ground granulated blast furnace slag and fly ashes with high calcium contents (such fly ashes display both pozzolanic and hydraulic behavior). The potential for using fly ash as a supplementary cementitious material in concrete has been known almost since the start of the last century (Anon 1914), although it wasn’t

Flux Bonded Flyash Bricks Blocks and Tiles The process is similar to the one in the conventional tile industry: fly ash is mixed with less than 10 % plastic clay and a few additives and tiles, bricks or blocks are pressed.

This national resource has beengainfully utilized for manufacture of pulverized fuel ash-lime bricks as asupplement to common burnt clay buildings bricks leading toconservation of natural resources and improvement in environmentquality. Pulverized fuel ash-lime bricks are obtained from materialsconsisting of pulverized fuel ash in major quantity, lime and anaccelerator acting as a …

Fly Ash bricks reduce emissions (Английский) Аннотация. Two Indians have invented a climate-friendly technology that produces bricks without using any coal whatsoever.

From Bricks To Blocks A Masonary Unit From Western

Do Fly Ash Bricks Conduct Heat More than Normal Bricks?

Fly ash bricks are hi-tech well-improved quality bricks used for construction of brick masonry structures. They are used as replacement for normal clay bricks and has better properties than it. Fly ash bricks competitive in comparison to the conventional clay bricks and provide enormous indirect

Comparision of AAC Blocks vs CLC blocks vs Red Clay Bricks

Fly ash presentation SlideShare

Leading Fly Ash Bricks Manufacturers And Suppliers in

Fly Ash Bricks v/s Clay Bricks or Conventional Bricks

Technical Specifcations of Hydraform Bricks Blocks

ash education book 2014 pdf – Gujarat Technological University Ahmedabad

Performance of bricks made using fly ash and bottom ash

Advantages and Disadvantages of using fly ash bricks over

Improving Soft Clay Soil Using Fly Ash As Material Of Column

Fly Ash bricks reduce emissions (Английский) Всемирный банк

Boral Limited Level 3 40 Mount Street North Sydney NSW

clay bricks is not available within the Kutch region, therefore the production of such bricks is not done in this region and hence the clay bricks are imported

The leading fly ash bricks manufacturers and suppliers in Rajasthan is Gypsona Plaster. It has one of the biggest fly Ash Bricks plants in India and are a famous fly ..

This national resource has beengainfully utilized for manufacture of pulverized fuel ash-lime bricks as asupplement to common burnt clay buildings bricks leading toconservation of natural resources and improvement in environmentquality. Pulverized fuel ash-lime bricks are obtained from materialsconsisting of pulverized fuel ash in major quantity, lime and anaccelerator acting as a …

The Fly ash of class C category was used as a raw material to total replacement of clay for making Fly ash bricks. In present study the effect of Fly ash with high replacement of clay mixed with

Rami Reddy, managing partner of VS Industries, which makes fly as bricks, said, “The cost of fly ash bricks is lower than clay bricks. While each fly ash brick costs around Rs 3.50-4, a clay brick

Use of fly ash as a raw material for the production of building bricks is not only viable alternative to clay but also a solution to difficult and expensive waste disposal …

Burnt Clay Bricks Versus Autoclaved Aerated Concrete Blocks A Comparative Analysis Radhika Shukla Architecture dept. MIET Nagpur University, Mumbai, India

ConclusionIf Fly Ash bricks can replace 50% of clay bricks then itwill reduce emission of green house gas by 435,000 tonseach year.Fly Ash based Bricks industries needs fragmented marketthat are serviced by plants located in the local area. Thepresent utilization of Fly Ash in the country is nominal ascompared to other advanced countries. Continuous effortis needed to increase the utilization

• AAC is made with major materials such as fly ash, cement, lime and an aerated agent. • AAC replaces clay bricks which are environmentally unsustainable • Being aerated , it contains 50 – 60 % of air, leading to light weight and low thermal conductivity

The new bricks and process have been given the name Fly ash Bricks. This work presents the results of testing This work presents the results of testing and the advantages gained by this type of bricks over conventional clay bricks.

Fly ash bricks Vs normal clay bricks The application of Fly ash bricks in various construction projects leading over traditional normal clay bricks due to its unique properties. A comparative study of fly ash bricks and normal clay bricks is summarized below in the table:

Raw Material for making blocks. The blocks can be made in Hydraform machine using Fly ash – Lime – Gypsum – Cement- Sand (Fal-G), other fly Ash based combination OR Soil-Cement (Compressed Stabilized Earth Blocks SEB) OR Stone Dust – Cement.

Coal Combustion By-Products Opportunities in fly ash trade and utilisation Coaltrans Asia – May 29-30th David Harris Asian Coal Ash Association Optimus Management Limited

Abstract: Fly ash brick (FAB) is a building material, specifically masonry units, containing class C fly ash and water, compressed at 28 MPa and cured for 24 hrs in a 66 °C steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freeze-thaw

What are the advantage and disadvantages of FLYASH BRICKS?

Do Fly Ash Bricks Conduct Heat More than Normal Bricks?

Coal Combustion By-Products Opportunities in fly ash trade and utilisation Coaltrans Asia – May 29-30th David Harris Asian Coal Ash Association Optimus Management Limited

AAC Blocks Vs Red Bricks both are the important material for constructing walls. Clay bricks & AAC blocks are used in walls as per their properties.

Endeavour Intelligent Equipments Pvt. Ltd. is a Leading Engineering Company engaged in the Manufacturing of Best Quality Equipments for Bricks & Blocks Making, Building Construction, Road Construction & Material Weighing, Batching, Mixing & Handling Projects.

Fly ash sand lime bricks – ash sand lime FLY ASH SAND LIME BRICKS In presence of moisture, fly ash reacts with lime at ordinary temperature and forms a compound possessing cementitious properties.

In this present study, fly ash and pond ash is effectively utilized in manufacturing of bricks. As per Das and As per Das and Segeran et al [1],in addition to superior conventional properties, fly ash or clay bricks have the advantages of

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly.

Fly ash bricks Vs normal clay bricks The application of Fly ash bricks in various construction projects leading over traditional normal clay bricks due to its unique properties. A comparative study of fly ash bricks and normal clay bricks is summarized below in the table:

Raw Material for making blocks. The blocks can be made in Hydraform machine using Fly ash – Lime – Gypsum – Cement- Sand (Fal-G), other fly Ash based combination OR Soil-Cement (Compressed Stabilized Earth Blocks SEB) OR Stone Dust – Cement.

Answer / kranap. Fly ash bricks are nowadays mostly used for construction and gaining its popularity over builders and engineers because of its high strength, uniformity and less consumption of …

15/01/2013 · Sir,comressive strength of 35kg/sqcm is good,and enough,t he life of wall depends upon water absorption of the bricks,less the water absorption life of the wall increases ,clc brick has less water absorption than any other bricks including aac blocks.

• AAC is made with major materials such as fly ash, cement, lime and an aerated agent. • AAC replaces clay bricks which are environmentally unsustainable • Being aerated , it contains 50 – 60 % of air, leading to light weight and low thermal conductivity

26/07/2017 · Fly ash bricks are lighter in weight and less costly than Clay bricks.Fly ash bricks are made of waste materials which come from the combustion of coal in thermal power plants.

Flux Bonded Flyash Bricks Blocks and Tiles The process is similar to the one in the conventional tile industry: fly ash is mixed with less than 10 % plastic clay and a few additives and tiles, bricks or blocks are pressed.

This paper presents the findings of investigation carried out on bricks made using fly ash and bottom ash using a non-conventional method. Bricks were cast using self-compacting mixtures of bottom ash, fly ash and cement eliminating both pressing and firing.

Fly ash bricks sales run into clay brick wall

Experimental Studies on Fly Ash-Sand-Lime Bricks with

Raw Material for making blocks. The blocks can be made in Hydraform machine using Fly ash – Lime – Gypsum – Cement- Sand (Fal-G), other fly Ash based combination OR Soil-Cement (Compressed Stabilized Earth Blocks SEB) OR Stone Dust – Cement.

ConclusionIf Fly Ash bricks can replace 50% of clay bricks then itwill reduce emission of green house gas by 435,000 tonseach year.Fly Ash based Bricks industries needs fragmented marketthat are serviced by plants located in the local area. Thepresent utilization of Fly Ash in the country is nominal ascompared to other advanced countries. Continuous effortis needed to increase the utilization

Engineering Services Technical Bulletin Clay Brick vs. Concrete Brick When comparing clay brick to concrete brick, it should be noted that both materials when properly installed can provide an attractive and structurally sound wall. However, when comparing the two products the following points should be kept in mind. 1. Concrete Brick (Reference ASTM Standard C55 Standard Specification for

Fly ash sand lime bricks – ash sand lime FLY ASH SAND LIME BRICKS In presence of moisture, fly ash reacts with lime at ordinary temperature and forms a compound possessing cementitious properties.

New Delhi: The government plans to make it mandatory for builders to use bricks made of fly ash, the residue produced by burning coal at power plants, in 20 locations across India to reduce pollution.

– Bricks can be made with 100% fly ash at room temperature at lower cost than traditional clay bricks – see the “Greenest Brick”. (Note: their website is several years out of date and I can’t find any recent news on their product.)

Improving Soft Clay Soil Using Fly Ash As Material Of Column 1Prof. Dr. K. E. A. Palaniappan, 2Mr. S. Prabhu 1Dean, VelTech MultiTech Dr RR Dr SR Engineering College, Avadi, Chennai- 62, …

The Fly ash of class C category was used as a raw material to total replacement of clay for making Fly ash bricks. In present study the effect of Fly ash with high replacement of clay mixed with

Abstract. Coal fly ash, a burnt residue of pulverized coal, is hazardous and its disposal is a problem. In Bangladesh, the annual generation of this waste is approximately 0.6 million tons.

24/07/2015 · We are hereby presenting a wide range of Fly ash Brick Making Machines from 2 Bricks per Stroke to 24 Bricks per stroke. We are providing Fly ash Brick Making Machines to …

Otherwise economically red clay brick (Class A) or fly ash brick is a better option. Incase of high rise structure, you should definitely use AAC blocks because it …

The fly ash samples utilised in this work were derived from a 0.1 MW Circulating Fluidised Bed (CFB) boiler firing South African bituminous coal with the addition of limestone for sulphur capture.

The colour of clay bricks is a direct consequence of the clay they are made from and the process of firing. Bricks remain stable and colour-fast and do not need to be rendered or painted. Clay brickwork is most commonly used uncoated to display the richness and texture of the material.

Fly Ash bricks reduce emissions (Английский) Аннотация. Two Indians have invented a climate-friendly technology that produces bricks without using any coal whatsoever.

What are the advantage and disadvantages of FLYASH BRICKS?

Synthesis of CFB-Coal Fly Ash Clay Bricks and Their

or clay-fly ash bricks, blocks and tiles on a priority basis over other users and if the demand from such agencies falls short of 20% of quantity the balance

Otherwise economically red clay brick (Class A) or fly ash brick is a better option. Incase of high rise structure, you should definitely use AAC blocks because it …

– Bricks can be made with 100% fly ash at room temperature at lower cost than traditional clay bricks – see the “Greenest Brick”. (Note: their website is several years out of date and I can’t find any recent news on their product.)

Endeavour Intelligent Equipments Pvt. Ltd. is a Leading Engineering Company engaged in the Manufacturing of Best Quality Equipments for Bricks & Blocks Making, Building Construction, Road Construction & Material Weighing, Batching, Mixing & Handling Projects.

26/07/2017 · Fly ash bricks are lighter in weight and less costly than Clay bricks.Fly ash bricks are made of waste materials which come from the combustion of coal in thermal power plants.

utilized more effectively in the development of building materials (Inclusion in fly ash bricks or clay bricks) for various construction applications. Sanjay Salla, Jayesh Pitroda (2013) experimented partial replacement of fly ash by Agro waste.

Fly Ash bricks reduce emissions (Английский) Аннотация. Two Indians have invented a climate-friendly technology that produces bricks without using any coal whatsoever.

The Fly ash of class C category was used as a raw material to total replacement of clay for making Fly ash bricks. In present study the effect of Fly ash with high replacement of clay mixed with

Flux Bonded Flyash Bricks Blocks and Tiles The process is similar to the one in the conventional tile industry: fly ash is mixed with less than 10 % plastic clay and a few additives and tiles, bricks or blocks are pressed.

In this paper, efforts has been made to study the behavior of fly ash bricks by taking different proportions of fly ash, cement, lime, gypsum and sand. Three types of fly ash bricks in the different percentage of cement such as 3%, 5% and without cement are designed and then various tests such as compressive strength test, water absorption test, efflorescence, weight test, structural test were

similar to that of common burnt clay bricks. The fly ash bricks are comparatively lighter in weight and stronger than common clay bricks. Since fly ash is being accumulated as waste material in large quantity near thermal power plants and creating serious environmental pollution problems, its utilisation as main raw material in the manufacture of bricks will not only create ample opportunities

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly.

Fly ash bricks can be extensively used in all building constructional activities similar to that of common burnt clay bricks. ur range of Fly Ash Bricks Making Machine includes Semi Automatic Fly Ash Bricks Making Machine and Fully Automatic Fly Ash Bricks Making Machine.

clay bricks is not available within the Kutch region, therefore the production of such bricks is not done in this region and hence the clay bricks are imported

business plan ash bricks in jharsuguda – SZM

Boral Limited Level 3 40 Mount Street North Sydney NSW

Endeavour Intelligent Equipments Pvt. Ltd. is a Leading Engineering Company engaged in the Manufacturing of Best Quality Equipments for Bricks & Blocks Making, Building Construction, Road Construction & Material Weighing, Batching, Mixing & Handling Projects.

Fly Ash Clay Bricks Fly ash clay bricks are manufactured with clay and fly ash—a byproduct of coal burning—fired at about 1,000 degrees C. Because fly ash contains a high volume of calcium oxide, this type of brick is sometimes described as self-cementing, since it expands when exposed to moisture.

Read also: Difference between Clay Bricks vs. Fly Ash Bricks Disadvantages of Fly Ash The quality of fly ash can affect the quality and strength of Cement concrete.

Abstract. Coal fly ash, a burnt residue of pulverized coal, is hazardous and its disposal is a problem. In Bangladesh, the annual generation of this waste is approximately 0.6 million tons.

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly.

Unlike other bricks including the common burnt clay bricks, sand lime bricks, fly ash bricks, concrete bricks, and fire clay bricks, CSEBs are cured on site and not fired using firewood.

(clay & shale): about 4 million m3. ANew Breakthrough of Technology From MeTech Inc SINTERED FLY ASH LIGHTWEIGHT AGGREGATE. Fly Ash Lightweight Aggregate FLY ASH AT A GLANCE Brief Introduction of LWA MeTech Fly Ash LWA Project Intro. Comparison of LWC & Normal Concrete MeTech Fly Ash LWA Project Intro. Go Green Fly Ash LWC Performance & Characteristics LWA Applications. MeTech Fly Ash …

Fly ash-lime-phosphogypsum (FaL-G) bricks are one of the best alternatives to the conventional burnt clay bricks. This paper gives the results of an experimental investigation in which the compressive strength, water absorption, density and durability of Fly ash-lime-phosphogypsum (FaL-G) bricks

clay bricks making machine in hubli in karnataka Hanje Hydrotech Fly ash brick making machine Fly ash bricks . Bricks Making Machine – Fly Ash Bricks Machine The Rotary Type Fly Ash Brick Making Machine makes bricks of the conventional size with a maximum brick size of 300 x 400 x 150 mm.

Answer / kranap. Fly ash bricks are nowadays mostly used for construction and gaining its popularity over builders and engineers because of its high strength, uniformity and less consumption of …

utilized more effectively in the development of building materials (Inclusion in fly ash bricks or clay bricks) for various construction applications. Sanjay Salla, Jayesh Pitroda (2013) experimented partial replacement of fly ash by Agro waste.

Fly Ash Lightweight Aggregate

Boral Limited Level 3 40 Mount Street North Sydney NSW

The leading fly ash bricks manufacturers and suppliers in Rajasthan is Gypsona Plaster. It has one of the biggest fly Ash Bricks plants in India and are a famous fly ..

15/01/2013 · Sir,comressive strength of 35kg/sqcm is good,and enough,t he life of wall depends upon water absorption of the bricks,less the water absorption life of the wall increases ,clc brick has less water absorption than any other bricks including aac blocks.

Improving Soft Clay Soil Using Fly Ash As Material Of Column 1Prof. Dr. K. E. A. Palaniappan, 2Mr. S. Prabhu 1Dean, VelTech MultiTech Dr RR Dr SR Engineering College, Avadi, Chennai- 62, …

Burnt Clay Bricks Versus Autoclaved Aerated Concrete Blocks A Comparative Analysis Radhika Shukla Architecture dept. MIET Nagpur University, Mumbai, India

Abstract. Coal fly ash, a burnt residue of pulverized coal, is hazardous and its disposal is a problem. In Bangladesh, the annual generation of this waste is approximately 0.6 million tons.

Fly Ash Bricks v/s Clay Bricks or Conventional Bricks

Fly Ash Lightweight Aggregate

Fly ash-lime-phosphogypsum (FaL-G) bricks are one of the best alternatives to the conventional burnt clay bricks. This paper gives the results of an experimental investigation in which the compressive strength, water absorption, density and durability of Fly ash-lime-phosphogypsum (FaL-G) bricks

The fly ash samples utilised in this work were derived from a 0.1 MW Circulating Fluidised Bed (CFB) boiler firing South African bituminous coal with the addition of limestone for sulphur capture.

FLY ASH BRICKS. FLY ASH BRICK MATERIA LS ARE CONTAINI NG CLASS C FLY ASH AND In presence of moisture.TYPES OF FLYASH BRICKS • Manufacturing process of clay flyash bricks by manual or extrusion process involves mixing of flyash (60 %) with clay of moderate plasticity • CLAY FLYASH- Flyash – Sand Lime Bricks. fly ash reacts with lime at

Fly Ash Bricks v/s Clay Bricks or Conventional Bricks No posts. No posts.

– Bricks can be made with 100% fly ash at room temperature at lower cost than traditional clay bricks – see the “Greenest Brick”. (Note: their website is several years out of date and I can’t find any recent news on their product.)

For manufacturing bagasse ash fly ash bricks, the best suited machinery is a Vibro – press machine, which is an indigenous low cost machine and can be run by

Unlike other bricks including the common burnt clay bricks, sand lime bricks, fly ash bricks, concrete bricks, and fire clay bricks, CSEBs are cured on site and not fired using firewood.

Use of fly ash as a raw material for the production of building bricks is not only viable alternative to clay but also a solution to difficult and expensive waste disposal …

NASIK FLY ASH BRICKS ASSOCIATION India South Asia

Do Fly Ash Bricks Conduct Heat More than Normal Bricks?

Use of fly ash as a raw material for the production of building bricks is not only viable alternative to clay but also a solution to difficult and expensive waste disposal …

Fly ash-lime-phosphogypsum (FaL-G) bricks are one of the best alternatives to the conventional burnt clay bricks. This paper gives the results of an experimental investigation in which the compressive strength, water absorption, density and durability of Fly ash-lime-phosphogypsum (FaL-G) bricks

Engineering Services Technical Bulletin Clay Brick vs. Concrete Brick When comparing clay brick to concrete brick, it should be noted that both materials when properly installed can provide an attractive and structurally sound wall. However, when comparing the two products the following points should be kept in mind. 1. Concrete Brick (Reference ASTM Standard C55 Standard Specification for

utilized more effectively in the development of building materials (Inclusion in fly ash bricks or clay bricks) for various construction applications. Sanjay Salla, Jayesh Pitroda (2013) experimented partial replacement of fly ash by Agro waste.

15/01/2013 · Sir,comressive strength of 35kg/sqcm is good,and enough,t he life of wall depends upon water absorption of the bricks,less the water absorption life of the wall increases ,clc brick has less water absorption than any other bricks including aac blocks.

In this paper, efforts has been made to study the behavior of fly ash bricks by taking different proportions of fly ash, cement, lime, gypsum and sand. Three types of fly ash bricks in the different percentage of cement such as 3%, 5% and without cement are designed and then various tests such as compressive strength test, water absorption test, efflorescence, weight test, structural test were

Otherwise economically red clay brick (Class A) or fly ash brick is a better option. Incase of high rise structure, you should definitely use AAC blocks because it …

similar to that of common burnt clay bricks. The fly ash bricks are comparatively lighter in weight and stronger than common clay bricks. Since fly ash is being accumulated as waste material in large quantity near thermal power plants and creating serious environmental pollution problems, its utilisation as main raw material in the manufacture of bricks will not only create ample opportunities

business plan ash bricks in jharsuguda orissa india. business plan i want to open a clay bricks project This page is about business plan i want to open a clay bricks project, , how to start a stone crushing business in india stone , clay bricks business plan – Gold Ore Crusher clay bricks business plan Stock .

Unlike other bricks including the common burnt clay bricks, sand lime bricks, fly ash bricks, concrete bricks, and fire clay bricks, CSEBs are cured on site and not fired using firewood.

clay bricks making machine in hubli in karnataka Hanje Hydrotech Fly ash brick making machine Fly ash bricks . Bricks Making Machine – Fly Ash Bricks Machine The Rotary Type Fly Ash Brick Making Machine makes bricks of the conventional size with a maximum brick size of 300 x 400 x 150 mm.

clay and shale, and volcanic ash. SCM’s that are hydraulic in behavior include ground granulated blast furnace slag and fly ashes with high calcium contents (such fly ashes display both pozzolanic and hydraulic behavior). The potential for using fly ash as a supplementary cementitious material in concrete has been known almost since the start of the last century (Anon 1914), although it wasn’t

Advantages and Disadvantages of using fly ash bricks over

Synthesis of CFB-Coal Fly Ash Clay Bricks and Their

Improving Soft Clay Soil Using Fly Ash As Material Of Column 1Prof. Dr. K. E. A. Palaniappan, 2Mr. S. Prabhu 1Dean, VelTech MultiTech Dr RR Dr SR Engineering College, Avadi, Chennai- 62, …

Use of fly ash as a raw material for the production of building bricks is not only viable alternative to clay but also a solution to difficult and expensive waste disposal …

Unlike other bricks including the common burnt clay bricks, sand lime bricks, fly ash bricks, concrete bricks, and fire clay bricks, CSEBs are cured on site and not fired using firewood.

Fly Ash bricks reduce emissions (Английский) Аннотация. Two Indians have invented a climate-friendly technology that produces bricks without using any coal whatsoever.

Read also: Difference between Clay Bricks vs. Fly Ash Bricks Disadvantages of Fly Ash The quality of fly ash can affect the quality and strength of Cement concrete.

Rami Reddy, managing partner of VS Industries, which makes fly as bricks, said, “The cost of fly ash bricks is lower than clay bricks. While each fly ash brick costs around Rs 3.50-4, a clay brick

2- Fly ash bricks are uniform in shape and size in comparison to burnt clay brick, therefore, require less mortar in brick work and finishing work resulting saving of cement mortar. 3- As, fly ash brick are machine made, quality control is better in comparison to burnt clay bricks.

Coal Combustion By-Products Opportunities in fly ash trade and utilisation Coaltrans Asia – May 29-30th David Harris Asian Coal Ash Association Optimus Management Limited

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly.

The Fly ash of class C category was used as a raw material to total replacement of clay for making Fly ash bricks. In present study the effect of Fly ash with high replacement of clay mixed with

AAC Blocks Vs Red Bricks both are the important material for constructing walls. Clay bricks & AAC blocks are used in walls as per their properties.

Compressive Strength of Fly Ash Brick with Addition of

Centre plans to make use of fly ash bricks mandatory

Use of fly ash as a raw material for the production of building bricks is not only viable alternative to clay but also a solution to difficult and expensive waste disposal …

AAC Blocks Vs Red Bricks both are the important material for constructing walls. Clay bricks & AAC blocks are used in walls as per their properties.

Background Information • Fly ash: by-product of coal combustion • Used to make various bricks • Causes damage to lungs if inhaled • Currently disposed of in wet landfills

clay and shale, and volcanic ash. SCM’s that are hydraulic in behavior include ground granulated blast furnace slag and fly ashes with high calcium contents (such fly ashes display both pozzolanic and hydraulic behavior). The potential for using fly ash as a supplementary cementitious material in concrete has been known almost since the start of the last century (Anon 1914), although it wasn’t

Answer / kranap. Fly ash bricks are nowadays mostly used for construction and gaining its popularity over builders and engineers because of its high strength, uniformity and less consumption of …

Abstract. Coal fly ash, a burnt residue of pulverized coal, is hazardous and its disposal is a problem. In Bangladesh, the annual generation of this waste is approximately 0.6 million tons.

Fly Ash Bricks v/s Clay Bricks or Conventional Bricks No posts. No posts.

Read also: Difference between Clay Bricks vs. Fly Ash Bricks Disadvantages of Fly Ash The quality of fly ash can affect the quality and strength of Cement concrete.

business plan ash bricks in jharsuguda orissa india. business plan i want to open a clay bricks project This page is about business plan i want to open a clay bricks project, , how to start a stone crushing business in india stone , clay bricks business plan – Gold Ore Crusher clay bricks business plan Stock .

Fly Ash bricks reduce emissions (Английский) Аннотация. Two Indians have invented a climate-friendly technology that produces bricks without using any coal whatsoever.

(clay & shale): about 4 million m3. ANew Breakthrough of Technology From MeTech Inc SINTERED FLY ASH LIGHTWEIGHT AGGREGATE. Fly Ash Lightweight Aggregate FLY ASH AT A GLANCE Brief Introduction of LWA MeTech Fly Ash LWA Project Intro. Comparison of LWC & Normal Concrete MeTech Fly Ash LWA Project Intro. Go Green Fly Ash LWC Performance & Characteristics LWA Applications. MeTech Fly Ash …

• AAC is made with major materials such as fly ash, cement, lime and an aerated agent. • AAC replaces clay bricks which are environmentally unsustainable • Being aerated , it contains 50 – 60 % of air, leading to light weight and low thermal conductivity

Endeavour Intelligent Equipments Pvt. Ltd. is a Leading Engineering Company engaged in the Manufacturing of Best Quality Equipments for Bricks & Blocks Making, Building Construction, Road Construction & Material Weighing, Batching, Mixing & Handling Projects.

utilized more effectively in the development of building materials (Inclusion in fly ash bricks or clay bricks) for various construction applications. Sanjay Salla, Jayesh Pitroda (2013) experimented partial replacement of fly ash by Agro waste.

clay bricks making machine in hubli in karnataka Hanje Hydrotech Fly ash brick making machine Fly ash bricks . Bricks Making Machine – Fly Ash Bricks Machine The Rotary Type Fly Ash Brick Making Machine makes bricks of the conventional size with a maximum brick size of 300 x 400 x 150 mm.

Fly Ash Bricks v/s Clay Bricks or Conventional Bricks

Comparision of AAC Blocks vs CLC blocks vs Red Clay Bricks

The fly ash samples utilised in this work were derived from a 0.1 MW Circulating Fluidised Bed (CFB) boiler firing South African bituminous coal with the addition of limestone for sulphur capture.

Raw Material for making blocks. The blocks can be made in Hydraform machine using Fly ash – Lime – Gypsum – Cement- Sand (Fal-G), other fly Ash based combination OR Soil-Cement (Compressed Stabilized Earth Blocks SEB) OR Stone Dust – Cement.

FLY ASH BRICKS. FLY ASH BRICK MATERIA LS ARE CONTAINI NG CLASS C FLY ASH AND In presence of moisture.TYPES OF FLYASH BRICKS • Manufacturing process of clay flyash bricks by manual or extrusion process involves mixing of flyash (60 %) with clay of moderate plasticity • CLAY FLYASH- Flyash – Sand Lime Bricks. fly ash reacts with lime at

The leading fly ash bricks manufacturers and suppliers in Rajasthan is Gypsona Plaster. It has one of the biggest fly Ash Bricks plants in India and are a famous fly ..

24/07/2015 · We are hereby presenting a wide range of Fly ash Brick Making Machines from 2 Bricks per Stroke to 24 Bricks per stroke. We are providing Fly ash Brick Making Machines to …

clay bricks is not available within the Kutch region, therefore the production of such bricks is not done in this region and hence the clay bricks are imported

Fly ash bricks sales run into clay brick wall

Experimental Studies on Pond Ash Brick

3/01/2013 · The cost fire clay bricks is going up making alternatives acceptable. … Manufacturing Process Cellular … The raw materials required are fly ash, cement, … »More detailed. High Performance Bricks from Fly Ash – Ash Library – University … manufacturing process uses … are among the factors that limited the use of fly ash in concrete … Approach to the Production of Bricks …

AAC Blocks Vs Red Bricks both are the important material for constructing walls. Clay bricks & AAC blocks are used in walls as per their properties.

Fly ash-lime-phosphogypsum (FaL-G) bricks are one of the best alternatives to the conventional burnt clay bricks. This paper gives the results of an experimental investigation in which the compressive strength, water absorption, density and durability of Fly ash-lime-phosphogypsum (FaL-G) bricks

The new bricks and process have been given the name Fly ash Bricks. This work presents the results of testing This work presents the results of testing and the advantages gained by this type of bricks over conventional clay bricks.

Fly Ash Bricks v/s Clay Bricks or Conventional Bricks No posts. No posts.

15/01/2013 · Sir,comressive strength of 35kg/sqcm is good,and enough,t he life of wall depends upon water absorption of the bricks,less the water absorption life of the wall increases ,clc brick has less water absorption than any other bricks including aac blocks.

clay bricks is not available within the Kutch region, therefore the production of such bricks is not done in this region and hence the clay bricks are imported

Otherwise economically red clay brick (Class A) or fly ash brick is a better option. Incase of high rise structure, you should definitely use AAC blocks because it …

People, who criticize Fly ash Bricks, Often throw a statement that fly ash bricks conduct more heat than normal clay bricks. Sadly, more people who are ignorant about fly ash bricks do believe that fly ash bricks conduct more heat than normal bricks.

utilized more effectively in the development of building materials (Inclusion in fly ash bricks or clay bricks) for various construction applications. Sanjay Salla, Jayesh Pitroda (2013) experimented partial replacement of fly ash by Agro waste.

clay and shale, and volcanic ash. SCM’s that are hydraulic in behavior include ground granulated blast furnace slag and fly ashes with high calcium contents (such fly ashes display both pozzolanic and hydraulic behavior). The potential for using fly ash as a supplementary cementitious material in concrete has been known almost since the start of the last century (Anon 1914), although it wasn’t

Fly ash bricks are generally used for making curtain and partition walls of the houses/ buildings. Fly ash bricks are used in domestic building in the category of low or middle-income groups mostly have single or two storied dwelling units.

Read also: Difference between Clay Bricks vs. Fly Ash Bricks Disadvantages of Fly Ash The quality of fly ash can affect the quality and strength of Cement concrete.

Fly ash bricks Vs normal clay bricks The application of Fly ash bricks in various construction projects leading over traditional normal clay bricks due to its unique properties. A comparative study of fly ash bricks and normal clay bricks is summarized below in the table:

Fly ash-lime-phosphogypsum cementitious binder A new

Do Fly Ash Bricks Conduct Heat More than Normal Bricks?

Fly Ash Clay Bricks Fly ash clay bricks are manufactured with clay and fly ash—a byproduct of coal burning—fired at about 1,000 degrees C. Because fly ash contains a high volume of calcium oxide, this type of brick is sometimes described as self-cementing, since it expands when exposed to moisture.

FLY ASH BRICKS. FLY ASH BRICK MATERIA LS ARE CONTAINI NG CLASS C FLY ASH AND In presence of moisture.TYPES OF FLYASH BRICKS • Manufacturing process of clay flyash bricks by manual or extrusion process involves mixing of flyash (60 %) with clay of moderate plasticity • CLAY FLYASH- Flyash – Sand Lime Bricks. fly ash reacts with lime at

Fly ash bricks are generally used for making curtain and partition walls of the houses/ buildings. Fly ash bricks are used in domestic building in the category of low or middle-income groups mostly have single or two storied dwelling units.

AAC Blocks Vs Red Bricks both are the important material for constructing walls. Clay bricks & AAC blocks are used in walls as per their properties.

Fly ash sand lime bricks – ash sand lime FLY ASH SAND LIME BRICKS In presence of moisture, fly ash reacts with lime at ordinary temperature and forms a compound possessing cementitious properties.

Burnt Clay Bricks Versus Autoclaved Aerated Concrete Blocks A Comparative Analysis Radhika Shukla Architecture dept. MIET Nagpur University, Mumbai, India

Otherwise economically red clay brick (Class A) or fly ash brick is a better option. Incase of high rise structure, you should definitely use AAC blocks because it …

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly.

business plan ash bricks in jharsuguda orissa india. business plan i want to open a clay bricks project This page is about business plan i want to open a clay bricks project, , how to start a stone crushing business in india stone , clay bricks business plan – Gold Ore Crusher clay bricks business plan Stock .

People, who criticize Fly ash Bricks, Often throw a statement that fly ash bricks conduct more heat than normal clay bricks. Sadly, more people who are ignorant about fly ash bricks do believe that fly ash bricks conduct more heat than normal bricks.

Differentiate between Clay Bricks and Fly Ash Bricks. The characteristics that differentiate between these bricks are – Fly ash bricks are of cement color while the colour of Clay bricks differs from burnt red to light brown depending on the type of clay used for manufacture of the bricks.

Rami Reddy, managing partner of VS Industries, which makes fly as bricks, said, “The cost of fly ash bricks is lower than clay bricks. While each fly ash brick costs around Rs 3.50-4, a clay brick

Engineering Services Technical Bulletin Clay Brick vs. Concrete Brick When comparing clay brick to concrete brick, it should be noted that both materials when properly installed can provide an attractive and structurally sound wall. However, when comparing the two products the following points should be kept in mind. 1. Concrete Brick (Reference ASTM Standard C55 Standard Specification for

Fly Ash Brick Plant Bricks Making Machine Manufacturer In

Difference Between Red Bricks and Fly ash Bricks Nirman

The colour of clay bricks is a direct consequence of the clay they are made from and the process of firing. Bricks remain stable and colour-fast and do not need to be rendered or painted. Clay brickwork is most commonly used uncoated to display the richness and texture of the material.

Flux Bonded Flyash Bricks Blocks and Tiles The process is similar to the one in the conventional tile industry: fly ash is mixed with less than 10 % plastic clay and a few additives and tiles, bricks or blocks are pressed.

– Bricks can be made with 100% fly ash at room temperature at lower cost than traditional clay bricks – see the “Greenest Brick”. (Note: their website is several years out of date and I can’t find any recent news on their product.)

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly.

(clay & shale): about 4 million m3. ANew Breakthrough of Technology From MeTech Inc SINTERED FLY ASH LIGHTWEIGHT AGGREGATE. Fly Ash Lightweight Aggregate FLY ASH AT A GLANCE Brief Introduction of LWA MeTech Fly Ash LWA Project Intro. Comparison of LWC & Normal Concrete MeTech Fly Ash LWA Project Intro. Go Green Fly Ash LWC Performance & Characteristics LWA Applications. MeTech Fly Ash …

People, who criticize Fly ash Bricks, Often throw a statement that fly ash bricks conduct more heat than normal clay bricks. Sadly, more people who are ignorant about fly ash bricks do believe that fly ash bricks conduct more heat than normal bricks.

Fly ash-lime-phosphogypsum (FaL-G) bricks are one of the best alternatives to the conventional burnt clay bricks. This paper gives the results of an experimental investigation in which the compressive strength, water absorption, density and durability of Fly ash-lime-phosphogypsum (FaL-G) bricks

Differentiate between Clay Bricks and Fly Ash Bricks. The characteristics that differentiate between these bricks are – Fly ash bricks are of cement color while the colour of Clay bricks differs from burnt red to light brown depending on the type of clay used for manufacture of the bricks.

Abstract. Coal fly ash, a burnt residue of pulverized coal, is hazardous and its disposal is a problem. In Bangladesh, the annual generation of this waste is approximately 0.6 million tons.

Gujarat Technological University Ahmedabad

Experimental Studies on Pond Ash Brick

Use of fly ash as a raw material for the production of building bricks is not only viable alternative to clay but also a solution to difficult and expensive waste disposal …

utilized more effectively in the development of building materials (Inclusion in fly ash bricks or clay bricks) for various construction applications. Sanjay Salla, Jayesh Pitroda (2013) experimented partial replacement of fly ash by Agro waste.

Improving Soft Clay Soil Using Fly Ash As Material Of Column 1Prof. Dr. K. E. A. Palaniappan, 2Mr. S. Prabhu 1Dean, VelTech MultiTech Dr RR Dr SR Engineering College, Avadi, Chennai- 62, …

Engineering Services Technical Bulletin Clay Brick vs. Concrete Brick When comparing clay brick to concrete brick, it should be noted that both materials when properly installed can provide an attractive and structurally sound wall. However, when comparing the two products the following points should be kept in mind. 1. Concrete Brick (Reference ASTM Standard C55 Standard Specification for

ConclusionIf Fly Ash bricks can replace 50% of clay bricks then itwill reduce emission of green house gas by 435,000 tonseach year.Fly Ash based Bricks industries needs fragmented marketthat are serviced by plants located in the local area. Thepresent utilization of Fly Ash in the country is nominal ascompared to other advanced countries. Continuous effortis needed to increase the utilization

The Fly ash of class C category was used as a raw material to total replacement of clay for making Fly ash bricks. In present study the effect of Fly ash with high replacement of clay mixed with

Fly Ash bricks are an alternative for the conventional bricks which can be used effectively to replace the conventional bricks. Various properties of these bricks were studied by different

Fly Ash bricks reduce emissions (Английский) Аннотация. Two Indians have invented a climate-friendly technology that produces bricks without using any coal whatsoever.

2- Fly ash bricks are uniform in shape and size in comparison to burnt clay brick, therefore, require less mortar in brick work and finishing work resulting saving of cement mortar. 3- As, fly ash brick are machine made, quality control is better in comparison to burnt clay bricks.

Use of bio-briquette ash for the development of bricks

fly ash bricks ppt frant.ppt Brick Scribd

Fly ash bricks are hi-tech well-improved quality bricks used for construction of brick masonry structures. They are used as replacement for normal clay bricks and has better properties than it. Fly ash bricks competitive in comparison to the conventional clay bricks and provide enormous indirect

FLY ASH BRICKS. FLY ASH BRICK MATERIA LS ARE CONTAINI NG CLASS C FLY ASH AND In presence of moisture.TYPES OF FLYASH BRICKS • Manufacturing process of clay flyash bricks by manual or extrusion process involves mixing of flyash (60 %) with clay of moderate plasticity • CLAY FLYASH- Flyash – Sand Lime Bricks. fly ash reacts with lime at

business plan ash bricks in jharsuguda orissa india. business plan i want to open a clay bricks project This page is about business plan i want to open a clay bricks project, , how to start a stone crushing business in india stone , clay bricks business plan – Gold Ore Crusher clay bricks business plan Stock .

Unlike other bricks including the common burnt clay bricks, sand lime bricks, fly ash bricks, concrete bricks, and fire clay bricks, CSEBs are cured on site and not fired using firewood.

clay bricks making machine in hubli in karnataka Hanje Hydrotech Fly ash brick making machine Fly ash bricks . Bricks Making Machine – Fly Ash Bricks Machine The Rotary Type Fly Ash Brick Making Machine makes bricks of the conventional size with a maximum brick size of 300 x 400 x 150 mm.

Rami Reddy, managing partner of VS Industries, which makes fly as bricks, said, “The cost of fly ash bricks is lower than clay bricks. While each fly ash brick costs around Rs 3.50-4, a clay brick

Background Information • Fly ash: by-product of coal combustion • Used to make various bricks • Causes damage to lungs if inhaled • Currently disposed of in wet landfills

Abstract: Fly ash brick (FAB) is a building material, specifically masonry units, containing class C fly ash and water, compressed at 28 MPa and cured for 24 hrs in a 66 °C steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freeze-thaw

Fly ash bricks Vs normal clay bricks The application of Fly ash bricks in various construction projects leading over traditional normal clay bricks due to its unique properties. A comparative study of fly ash bricks and normal clay bricks is summarized below in the table:

New Delhi: The government plans to make it mandatory for builders to use bricks made of fly ash, the residue produced by burning coal at power plants, in 20 locations across India to reduce pollution.

A cost analysis for the BBA bricks and the commercially, locally available burnt clay and fly ash bricks was completed. The cost of BBA bricks (INR 2.01) was estimated as 55% less than that of conventional bricks (INR 4.55). However, BBA bricks were found to be 63% cheaper compared to traditional burnt clay bricks (INR 5.5).

Lime sand fly ash brick ion flow chart a detailed parison of aac blocks vs clay bricks clip image014 manufacturing process of eco bricks earthen Manufacturing Process KameiseitoHow Brick Is Made Material Ion Process ManufactureHow…Continue Reading

Fly ash sand lime bricks – ash sand lime FLY ASH SAND LIME BRICKS In presence of moisture, fly ash reacts with lime at ordinary temperature and forms a compound possessing cementitious properties.

The Fly ash of class C category was used as a raw material to total replacement of clay for making Fly ash bricks. In present study the effect of Fly ash with high replacement of clay mixed with

24/07/2015 · We are hereby presenting a wide range of Fly ash Brick Making Machines from 2 Bricks per Stroke to 24 Bricks per stroke. We are providing Fly ash Brick Making Machines to …

What are the advantage and disadvantages of FLYASH BRICKS?

NASIK FLY ASH BRICKS ASSOCIATION India South Asia

Lime sand fly ash brick ion flow chart a detailed parison of aac blocks vs clay bricks clip image014 manufacturing process of eco bricks earthen Manufacturing Process KameiseitoHow Brick Is Made Material Ion Process ManufactureHow…Continue Reading

– Bricks can be made with 100% fly ash at room temperature at lower cost than traditional clay bricks – see the “Greenest Brick”. (Note: their website is several years out of date and I can’t find any recent news on their product.)

People, who criticize Fly ash Bricks, Often throw a statement that fly ash bricks conduct more heat than normal clay bricks. Sadly, more people who are ignorant about fly ash bricks do believe that fly ash bricks conduct more heat than normal bricks.

Raw Material for making blocks. The blocks can be made in Hydraform machine using Fly ash – Lime – Gypsum – Cement- Sand (Fal-G), other fly Ash based combination OR Soil-Cement (Compressed Stabilized Earth Blocks SEB) OR Stone Dust – Cement.

Fly ash bricks can be extensively used in all building constructional activities similar to that of common burnt clay bricks. ur range of Fly Ash Bricks Making Machine includes Semi Automatic Fly Ash Bricks Making Machine and Fully Automatic Fly Ash Bricks Making Machine.

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly.

Endeavour Intelligent Equipments Pvt. Ltd. is a Leading Engineering Company engaged in the Manufacturing of Best Quality Equipments for Bricks & Blocks Making, Building Construction, Road Construction & Material Weighing, Batching, Mixing & Handling Projects.

In this present study, fly ash and pond ash is effectively utilized in manufacturing of bricks. As per Das and As per Das and Segeran et al [1],in addition to superior conventional properties, fly ash or clay bricks have the advantages of

Fly Ash bricks reduce emissions (Английский) Аннотация. Two Indians have invented a climate-friendly technology that produces bricks without using any coal whatsoever.

What are the advantage and disadvantages of FLYASH BRICKS?

Fly ash brick making machine YouTube

Use of bio-briquette ash for the development of bricks

People, who criticize Fly ash Bricks, Often throw a statement that fly ash bricks conduct more heat than normal clay bricks. Sadly, more people who are ignorant about fly ash bricks do believe that fly ash bricks conduct more heat than normal bricks.

Do Fly Ash Bricks Conduct Heat More than Normal Bricks?

Leading Fly Ash Bricks Manufacturers And Suppliers in

NASIK FLY ASH BRICKS ASSOCIATION India South Asia

New Delhi: The government plans to make it mandatory for builders to use bricks made of fly ash, the residue produced by burning coal at power plants, in 20 locations across India to reduce pollution.

Rice Hull Ash Brick Formula With No Cement Natural

Read also: Difference between Clay Bricks vs. Fly Ash Bricks Disadvantages of Fly Ash The quality of fly ash can affect the quality and strength of Cement concrete.

Leading Fly Ash Bricks Manufacturers And Suppliers in

BRICKS WITH TOTAL REPLACEMENT OF CLAY BY FLY ASH MIXED

business plan ash bricks in jharsuguda – SZM

Coal Combustion By-Products Opportunities in fly ash trade and utilisation Coaltrans Asia – May 29-30th David Harris Asian Coal Ash Association Optimus Management Limited

Types of Bricks Clay Bricks Fly Ash Bricks Fire Bricks

This paper presents the findings of investigation carried out on bricks made using fly ash and bottom ash using a non-conventional method. Bricks were cast using self-compacting mixtures of bottom ash, fly ash and cement eliminating both pressing and firing.

Compressive Strength of Fly Ash Brick with Addition of

Experimental Studies on Fly Ash-Sand-Lime Bricks with

The Fly ash of class C category was used as a raw material to total replacement of clay for making Fly ash bricks. In present study the effect of Fly ash with high replacement of clay mixed with

From Bricks To Blocks A Masonary Unit From Western

What are the advantage and disadvantages of FLYASH BRICKS?

This paper presents the findings of investigation carried out on bricks made using fly ash and bottom ash using a non-conventional method. Bricks were cast using self-compacting mixtures of bottom ash, fly ash and cement eliminating both pressing and firing.

Rice Hull Ash Brick Formula With No Cement Natural

Use of fly ash as a raw material for the production of building bricks is not only viable alternative to clay but also a solution to difficult and expensive waste disposal …

fly ash bricks manufacturing process with cement filetype pdf

24/07/2015 · We are hereby presenting a wide range of Fly ash Brick Making Machines from 2 Bricks per Stroke to 24 Bricks per stroke. We are providing Fly ash Brick Making Machines to …

CLC Bricks comparison with Red Bricks Blogger

Advantages and Disadvantages of using fly ash bricks over

Make high quality low cost building bricks save costs

Background Information • Fly ash: by-product of coal combustion • Used to make various bricks • Causes damage to lungs if inhaled • Currently disposed of in wet landfills

Fly Ash Concrete Advantages and Disadvantages WFM

Use of bio-briquette ash for the development of bricks

AAC BLOCKS VS CONVENTIONAL BLOCKS Green Building

– Bricks can be made with 100% fly ash at room temperature at lower cost than traditional clay bricks – see the “Greenest Brick”. (Note: their website is several years out of date and I can’t find any recent news on their product.)

Centre plans to make use of fly ash bricks mandatory

Fly ash-lime-phosphogypsum (FaL-G) bricks are one of the best alternatives to the conventional burnt clay bricks. This paper gives the results of an experimental investigation in which the compressive strength, water absorption, density and durability of Fly ash-lime-phosphogypsum (FaL-G) bricks

NASIK FLY ASH BRICKS ASSOCIATION India South Asia

Comparision of AAC Blocks vs CLC blocks vs Red Clay Bricks

Burnt Clay Bricks Versus Autoclaved Aerated Concrete Blocks A Comparative Analysis Radhika Shukla Architecture dept. MIET Nagpur University, Mumbai, India

Compressive Strength of Fly Ash Brick with Addition of

Fly Ash Sand Lime Bricks [PDF Document]

Read also: Difference between Clay Bricks vs. Fly Ash Bricks Disadvantages of Fly Ash The quality of fly ash can affect the quality and strength of Cement concrete.

Rice Hull Ash Brick Formula With No Cement Natural

Fly ash bricks Vs normal clay bricks The application of Fly ash bricks in various construction projects leading over traditional normal clay bricks due to its unique properties. A comparative study of fly ash bricks and normal clay bricks is summarized below in the table:

Coaltrans Asia May 29-30 Coal Combustion By-Products

AAC BLOCKS VS CONVENTIONAL BLOCKS Green Building

Experimental Studies on Fly Ash-Sand-Lime Bricks with

The Fly ash of class C category was used as a raw material to total replacement of clay for making Fly ash bricks. In present study the effect of Fly ash with high replacement of clay mixed with

Performance of bricks made using fly ash and bottom ash

• AAC is made with major materials such as fly ash, cement, lime and an aerated agent. • AAC replaces clay bricks which are environmentally unsustainable • Being aerated , it contains 50 – 60 % of air, leading to light weight and low thermal conductivity

Fly Ash Bricks mse.washington.edu

Abstract: Fly ash brick (FAB) is a building material, specifically masonry units, containing class C fly ash and water, compressed at 28 MPa and cured for 24 hrs in a 66 °C steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freeze-thaw

Fly ash-lime-phosphogypsum cementitious binder A new

Types of Bricks Clay Bricks Fly Ash Bricks Fire Bricks

(clay & shale): about 4 million m3. ANew Breakthrough of Technology From MeTech Inc SINTERED FLY ASH LIGHTWEIGHT AGGREGATE. Fly Ash Lightweight Aggregate FLY ASH AT A GLANCE Brief Introduction of LWA MeTech Fly Ash LWA Project Intro. Comparison of LWC & Normal Concrete MeTech Fly Ash LWA Project Intro. Go Green Fly Ash LWC Performance & Characteristics LWA Applications. MeTech Fly Ash …

Experimental Studies on Pond Ash Brick

– Bricks can be made with 100% fly ash at room temperature at lower cost than traditional clay bricks – see the “Greenest Brick”. (Note: their website is several years out of date and I can’t find any recent news on their product.)

fly ash bricks manufacturing process with cement filetype pdf

Fly ash bricks are generally used for making curtain and partition walls of the houses/ buildings. Fly ash bricks are used in domestic building in the category of low or middle-income groups mostly have single or two storied dwelling units.

A Comparative Analysis ijert.org

3/01/2013 · The cost fire clay bricks is going up making alternatives acceptable. … Manufacturing Process Cellular … The raw materials required are fly ash, cement, … »More detailed. High Performance Bricks from Fly Ash – Ash Library – University … manufacturing process uses … are among the factors that limited the use of fly ash in concrete … Approach to the Production of Bricks …

CLC Bricks comparison with Red Bricks Blogger

– Bricks can be made with 100% fly ash at room temperature at lower cost than traditional clay bricks – see the “Greenest Brick”. (Note: their website is several years out of date and I can’t find any recent news on their product.)

Fly ash presentation SlideShare

A Comparative Analysis ijert.org

– Bricks can be made with 100% fly ash at room temperature at lower cost than traditional clay bricks – see the “Greenest Brick”. (Note: their website is several years out of date and I can’t find any recent news on their product.)

Compressive Strength of Fly Ash Brick with Addition of

Fly ash presentation SlideShare

Fly Ash Lightweight Aggregate

In this paper, efforts has been made to study the behavior of fly ash bricks by taking different proportions of fly ash, cement, lime, gypsum and sand. Three types of fly ash bricks in the different percentage of cement such as 3%, 5% and without cement are designed and then various tests such as compressive strength test, water absorption test, efflorescence, weight test, structural test were

Fly Ash Concrete Advantages and Disadvantages WFM

From Bricks To Blocks A Masonary Unit From Western

Otherwise economically red clay brick (Class A) or fly ash brick is a better option. Incase of high rise structure, you should definitely use AAC blocks because it …

Types of Bricks Clay Bricks Fly Ash Bricks Fire Bricks

Experimental Studies on Pond Ash Brick

The fly ash samples utilised in this work were derived from a 0.1 MW Circulating Fluidised Bed (CFB) boiler firing South African bituminous coal with the addition of limestone for sulphur capture.

Types of Bricks Clay Bricks Fly Ash Bricks Fire Bricks

Leading Fly Ash Bricks Manufacturers And Suppliers in

AAC Blocks Vs Red Bricks both are the important material for constructing walls. Clay bricks & AAC blocks are used in walls as per their properties.

Difference Between Red Bricks and Fly ash Bricks Nirman

Types of Bricks Clay Bricks Fly Ash Bricks Fire Bricks

Experimental Studies on Fly Ash-Sand-Lime Bricks with

clay bricks making machine in hubli in karnataka Hanje Hydrotech Fly ash brick making machine Fly ash bricks . Bricks Making Machine – Fly Ash Bricks Machine The Rotary Type Fly Ash Brick Making Machine makes bricks of the conventional size with a maximum brick size of 300 x 400 x 150 mm.

Fly ash bricks sales run into clay brick wall

Fly ash bricks can be extensively used in all building constructional activities similar to that of common burnt clay bricks. ur range of Fly Ash Bricks Making Machine includes Semi Automatic Fly Ash Bricks Making Machine and Fully Automatic Fly Ash Bricks Making Machine.

Experimental Studies on Pond Ash Brick

Fly Ash Bricks v/s Clay Bricks or Conventional Bricks No posts. No posts.

BRICKS WITH TOTAL REPLACEMENT OF CLAY BY FLY ASH MIXED

Gujarat Technological University Ahmedabad

Fly Ash bricks reduce emissions (Английский) Всемирный банк

In this present study, fly ash and pond ash is effectively utilized in manufacturing of bricks. As per Das and As per Das and Segeran et al [1],in addition to superior conventional properties, fly ash or clay bricks have the advantages of

Do Fly Ash Bricks Conduct Heat More than Normal Bricks?

A Comparative Analysis ijert.org

Coal Combustion By-Products Opportunities in fly ash trade and utilisation Coaltrans Asia – May 29-30th David Harris Asian Coal Ash Association Optimus Management Limited

Synthesis of CFB-Coal Fly Ash Clay Bricks and Their

Fly ash brick making machine YouTube

The leading fly ash bricks manufacturers and suppliers in Rajasthan is Gypsona Plaster. It has one of the biggest fly Ash Bricks plants in India and are a famous fly ..

Fly ash brick making machine YouTube

NASIK FLY ASH BRICKS ASSOCIATION India South Asia

Abstract: Fly ash brick (FAB) is a building material, specifically masonry units, containing class C fly ash and water, compressed at 28 MPa and cured for 24 hrs in a 66 °C steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freeze-thaw

Centre plans to make use of fly ash bricks mandatory

Coaltrans Asia May 29-30 Coal Combustion By-Products

Improving Soft Clay Soil Using Fly Ash As Material Of Column 1Prof. Dr. K. E. A. Palaniappan, 2Mr. S. Prabhu 1Dean, VelTech MultiTech Dr RR Dr SR Engineering College, Avadi, Chennai- 62, …

Types of Bricks Clay Bricks Fly Ash Bricks Fire Bricks

Fly ash bricks sales run into clay brick wall

Synthesis of CFB-Coal Fly Ash Clay Bricks and Their

For manufacturing bagasse ash fly ash bricks, the best suited machinery is a Vibro – press machine, which is an indigenous low cost machine and can be run by

Centre plans to make use of fly ash bricks mandatory

Gujarat Technological University Ahmedabad

business plan ash bricks in jharsuguda – SZM

ConclusionIf Fly Ash bricks can replace 50% of clay bricks then itwill reduce emission of green house gas by 435,000 tonseach year.Fly Ash based Bricks industries needs fragmented marketthat are serviced by plants located in the local area. Thepresent utilization of Fly Ash in the country is nominal ascompared to other advanced countries. Continuous effortis needed to increase the utilization

Compressive Strength of Fly Ash Brick with Addition of

Leading Fly Ash Bricks Manufacturers And Suppliers in

This paper presents the findings of investigation carried out on bricks made using fly ash and bottom ash using a non-conventional method. Bricks were cast using self-compacting mixtures of bottom ash, fly ash and cement eliminating both pressing and firing.

flowsheet for fly ash bricks comelmeccanica.it

Comparision of AAC Blocks vs CLC blocks vs Red Clay Bricks

fly ash bricks manufacturing process with cement filetype pdf

People, who criticize Fly ash Bricks, Often throw a statement that fly ash bricks conduct more heat than normal clay bricks. Sadly, more people who are ignorant about fly ash bricks do believe that fly ash bricks conduct more heat than normal bricks.

Fly ash-lime-phosphogypsum cementitious binder A new

Raw Material for making blocks. The blocks can be made in Hydraform machine using Fly ash – Lime – Gypsum – Cement- Sand (Fal-G), other fly Ash based combination OR Soil-Cement (Compressed Stabilized Earth Blocks SEB) OR Stone Dust – Cement.

AAC BLOCKS VS CONVENTIONAL BLOCKS Green Building

Fly ash brick making machine YouTube

Difference Between Red Bricks and Fly ash Bricks Nirman

26/07/2017 · Fly ash bricks are lighter in weight and less costly than Clay bricks.Fly ash bricks are made of waste materials which come from the combustion of coal in thermal power plants.

Advantages and Disadvantages of using fly ash bricks over

fly ash bricks machine in hubli karnataka spitsid.eu

Fly Ash Brick Plant Bricks Making Machine Manufacturer In

In this present study, fly ash and pond ash is effectively utilized in manufacturing of bricks. As per Das and As per Das and Segeran et al [1],in addition to superior conventional properties, fly ash or clay bricks have the advantages of

fly ash bricks manufacturing process with cement filetype pdf

fly ash bricks ppt frant.ppt Brick Scribd

Fly Ash Sand Lime Bricks [PDF Document]