Fly ash bricks composition pdf

The most-often-used specifications for fly ash ar e ASTM C 618 and AASH TO M 295.Two major classes of fly ash are specified in ASTM C 618 on the basis of their chemical composition …

7 Mineral composition and clay index for the samples containing fly ash, clay, and clay plus shale 6 8 Total weight loss and shrinkage for Batch 1 bricks fired at Brick Plant I 6

Fly Ash Brick (1).pdf Brick – Scribd – Read books Clay brick are uneven in shape as the mostly Uniform in shape and smooth in finish as the clay bricks are made manually.Air exchange is poor in comparison to normal clay bricks. soil.

composition as a coarser material to control water absorption in the final product. Pulverized fuel ash reacts with lime in presence of moisture from a calcium hydrate which is a binder material. Thus pulverized fuel ash – lime in presence of moisture form a calcium – silicate hydrate which is binder material. Thus pulverized fuel ash – lime brick is a chemically ended bricks. These

Fly ash brick are lighter as the main composition is fly ash. Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash brick. The cost of fly ash brick is approximate 30%lower

bricks as it is 18.16% in case of normal clay bricks and it decreases to 9.60% when 40% of fly ash is added in the manufactured sample. On the other hand a reverse pattern is perceived on addition of rice husk ash instead of fly ash

Fly ash bricks were studied by R.L. Day and et al. [2] they used fly ash from western Canada as a main composition up to 70-100% mixed with bottom ash and NaOH, Na 2 CO 3 or Na 2 SiO 3 were added for better solidity of brick samples.

ii strength characteristic study of fly ash composite material a thesis submitted in partial fulfillment of the requirements for the degree of

High Performance Bricks from Fly Ash . Obada Kayali. 1 . 1. School of Aerospace, Civil and Mechanical Engineering, University of New South Wales at The Australian Defence Force …

Homepage » Fly Ash Bricks » Fly Ash Bricks Mixing Proportion – 3 Important Formulas. Fly Ash Bricks Mixing Proportion – 3 Important Formulas. admin. August 15, 2013 . Fly Ash Bricks. Flyash Bricks can be manufactured using 3 different mixing ratios of different materials. You can select the best suitable mixing ratio according to the availability of raw materials and market requirement

Paper on use of Fly ash for Brick making (Clay-fly ash bricks) 1.0 Background Fly ash is a coal combustion by-product – a finely divided residue resulting from combustion of coal in power plants. In the thermal power stations, coal is pulverized into fine powder and pumped into the boiler along with compressed air. Coal powder is fired to generate heat, which in turn produces steam to run

of fly ash bricks for testing purpose to ensure the required minimum compressive strength of bricks should not be less than 5 N/sq.mm or more than 10 N/sq.mm. The water absorption is tested weighing the bricks in dry condition then by immersing the brick in water for 24 hours and weighing it thereafter. The water absorption of the bricks should not n be then dispatched to market. A. Problem

ash is composed of the non-combustible mineral portion of coal consumed in a coal fuelled power plant.Fly ash is a powdery substance obtained from the dust collectors in …

WATER ABSORPTION OF FLY ASH AND RICE HUSK ASH BRICKS

Manufacturing Bricks with Fly Ash and Advanced Coal

The characteristics of fly ash depend upon the quality of lignite/coal and the efficiency of boilers.a Characteristics of Fly ash The physical and chemical properties of Fly Ash are tabulated below 4. The fly ash generation in India Thermal Stations is likely to shoot up to 170 million tones in 2010 from the present level of 100 million tones. i.4.

Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash The cost of fly ash brick is approximate 30%lower brick. Clay brick are uneven in shape as the mostly Uniform in shape and smooth in finish as the clay bricks are made manually.

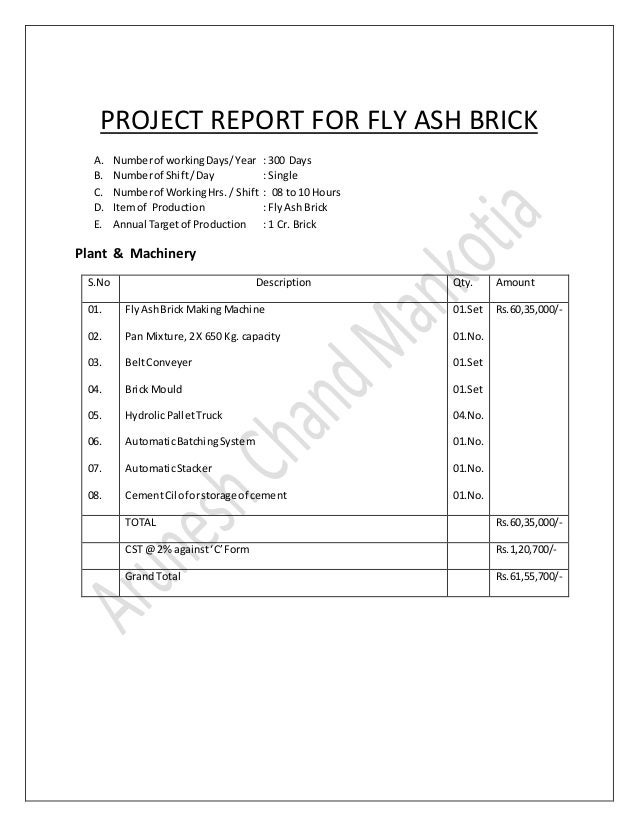

FLY ASH BRICKS Fly ash bricks manufacturing units can be set up nearby thermalpower stations.Because the main raw materialis fly ash is generated by thermal power stations in big quanity . Fly ash supplied by thermal power stations at free of cost the entreprenuer has to bare only transportations charges from thermalpower stations to the fly ash bricks manufacturing unit. . There …

9/01/2016 · Dear sir, Enjoy your day! With the latest technologies through planning and development, we, “prem nath & brothers”, have carved a valuable niche for our products across the globe.

Use of Fly Ash Brick: Fly Ash Bricks can be used as replacement of common burnt clay building bricks. Market Price: As per the analysis of SOR item no.per 1000 brick + freight in Lucknow (U. compact and uniform in shape.Office building construction by Greater Noida Development Authority . Faridabad in Haryana and Talchar – Kaniha in Orissa .

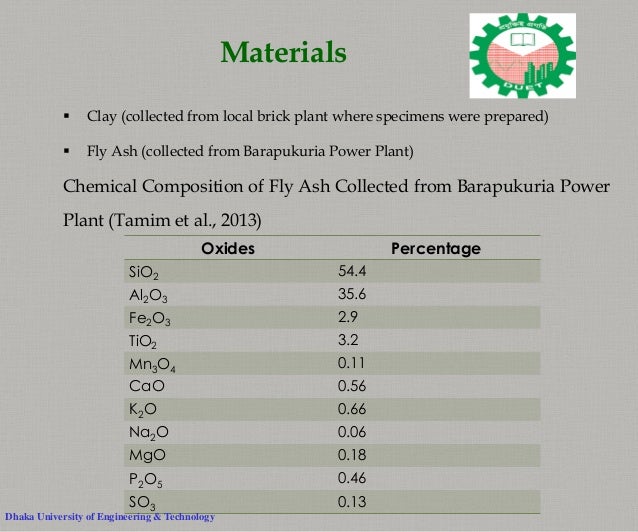

The properties of fly ash bricks depend mainly on two factors: ) the energy content of the fly ash used and 1 ) 2 the chemical composition of the fly ash. Table 1 shows the chemical composition of fly ash from two different

and fly ash The main aim of this research was to compare the compressive strength of the bricks, so for this purpose different percentage of materials were separately added 5%, 10%, 15%,

Fly ash contains Co 2 emitted from Thermal power plants, industries using coal as a fuel emits unwanted ash and smoke from which fly ash is produced. In all the power plants and industries, they separate the fly ash by using the cyclone converter. This fly ash is then used as …

Fly ash is one of the major residues generated during combustion of coal in thermal power plants. Fly ash brick technology is Fly ash brick technology is the process of converting industrial waste material into quality building material.

Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash The cost of fly ash brick is approximate 30%lower brick. plastering required in normal cases. But this can be improved by adding marble/ stone dust and cementing materials. Fly ash brick are lighter as the main composition is fly ash. 3. Only modular size can be produced.Demerit of Fly Ash

Fly ash bricks are lighter as the main composition is fly ash. Clay bricks are heavier as compared to fly ash bricks. Fly ash bricks are less porous. Clay bricks are more porous. The cost of fly ash brick is approximate 30% lower than clay brick. The cost of clay brick is higher than fly ash brick. This is made by using by-product of Thermal Power Plant, which save environment from being

The most-often-used specifications for fly ash are ASTM C 618 and AASHTO M 295.Two major classes of fly ash are specified in ASTM C 618 on the basis of their chemical composition resulting from the type of coal burned; these are designated Class F and Class C. Class F is fly ash normally 47 JOURNAL Of NUCLEAR And Related TECHNOLOGIES, Volume 4, Special Edition, 2007 produced …

Alibaba.com offers 79 fly ash bricks composition products. About 3% of these are engineered flooring, 2% are aluminum composite panels. A wide variety of fly ash bricks composition options are available to you, such as free samples.

My house ground floor is made with red clay bricks.Now i constructed first floor with fly ash brick but in 3 to 4 months area made with fly ash have crack in plaster..the constructor says it happens in fly ash brick in summer. Is it true..if yes how to treat it.

Based on Fly-ash bricks and clay bricks the data collected, Data will be collected through questionnaires and personal interviews targeting residential building and infrastructure projects. We can easily able to analysis of fly

Strengthening of Fly Ash Bricks By Ironite IOSR Journals

Fly Ash bricks are an alternative for the conventional bricks which can be used effectively to replace the conventional bricks. Various properties of these bricks were studied by different researchers and they found that these bricks can be used for construction of low cost houses in the area in the vicinity of thermal power plant. This paper is an attempt to study the strength and durability

silica) in the fly ash varies depending on the quartz content of the coal. Class C fly ash may have 1-7% Class C fly ash may have 1-7% free CaO and calcium sulfate as well as calcium aluminosilicate glass.

Fly Ash Facts for Highway Engineers (ASTM) Specification C 618] defines the chemical composition of Class C and Class F fly ash. Class C ashes are generally derived from sub-bituminous coals and consist primarily of calcium alumino-sulfate glass, as well as quartz, tricalcium aluminate, and free lime (CaO). Class C ash is also referred to as high calcium fly ash because it typically

Karthikeyan and M Ponni (3) studied the utilisation of fly ash in bricks. The fly ash can The fly ash can be effectively used for manufacture of bricks using fly-ash, lime, sand and gypsum.

Secondly for fly ash bricks were prepared by using cement and stone powder in varying proportions. Also, the bricks were prepared from flyash, lime, sand and gypsum. The bricks were prepared by using different proportions of fly ash, lime, sand and gypsum. Initially the lime was slaked with water and made it soft. The flyash was thoroughly mixed with fly ash shows cementious property. The sand

Strengthening Of Fly Ash Bricks By Ironite www.iosrjournals.org 22 Page Lime Quick Lime or hydrated lime or both can be mixed in the composition.

COMPARISON BETWEEN FLY ASH BRICKS AND CLAY BRICKS NORMAL CLAY BRICKS FLY ASH BRICKS Varying colour as per soil Uniform pleasing colour like cement Uneven shape as hand made Uniform in shape and smooth in finish Lightly bonded Dense composition Plastering required No plastering required Heavier in weight Lighter in weight Compressive strength is around 35 Kg/cm2 … – use of fly ash in concrete pdf stabilizers in unfired bricks, but people have experimented with using fly ash, rice husk ash, and other common materials to improve the quality of their bricks (Maini, 2010). Portland cement is particularly good for stabilizing bricks made from sandy soils.

Raw material: the raw materials of fly ash brick mainly includes cement, slag, fly ash and other construction rubbish, but the fly ash bricks have high strength. For red bricks, they are made from clay. We can conclude that the fly ash bricks have lower cost and higher strength than the red bricks.

however, bricks made from fly ash/silica sa nd and fly ash/common sand would need dry densities of approximately 1.40 t/m 3 and 1.60 t/m 3 , respectively. Compared to dry densities of

BURNTCLAY FLY ASH BUILDING BRICKS. ‘SPECIFICATION 1 SCOPE 5 GENERAL QUALITY 1.1 This standard lays down requirements for-classification, general quality, dimensions and physical requirements of common burnt clay building bricks used in buildings. NOTE – Burnt clay ftyash bricks having compres sive strength less than 30 N/mm’ approximately 300 kgf/em- are covered in this …

KEYWORDS: brick, fly ash Abstract A new approach to the production of bricks was carried out by using lignite fly ash. The possibility of fly ash for use as building material was investigated. Pure fly ash and certain amount of mixing water (17.5 mass-%) were used as body composition for the production of brick …

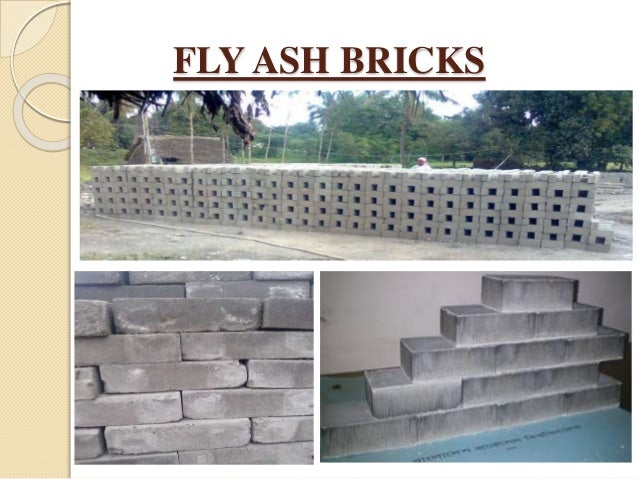

Fly-Ash Bricks and Blocks are largely used in various constructions, such as load bearing and pillar structure Buildings, Boundary walls, Roads, Culverts, Pavements, and wherever conventional bricks can be …

Fly ash contains Co 2 emitted from Thermal power plants, industries using coal as a fuel emits unwanted ash and smoke from which fly ash is produced. In all the power plants and industries, they separate the fly ash by using the cyclone converter. This fly ash is then used as a raw material for manufacture of bricks.

Volume mass, compressive strength, water uptake and water absorption of pressed test samples made of a mixture of coal fly-ash, slag and sodium silicate solution (water-glass) were determined.

The building bricks contained 20, 30, or 40 vol% of fly ash from two different Illinois sources, and the paving bricks produced contained 20 vol% of fly ash from one of these two sources.

A fly ash composition is provided which includes an amount of lithium carbonate to reduce alkali silica reactivity when the fly ash composition is used in concrete applications. The fly ash composition includes from about 0.5 wt.% to about 98% wt.% subbituminous fly ash and from about 0.5 wt.% to about 3 wt.% lithium carbonate.

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly. Disadvantages are, the outer surface or shell of brick is hard compared to inner core, in case a chase is cut to lay conduits and pipes, the chances of development of cracks later in the

Directors: C.D Billett, M.F.Hovy, A. Thedvall MATERIAL SAFETY DATA SHEET FLY ASH Aug 2011 1. IDENTIFICATION OF MATERIAL Identity: Classified Fly Ash or Unclassified Fly Ash

F fly ash depends on the basic clay composition of coal and then, on the operating parameters of the power plants with special emphasis on combustion temperature, fineness and

Bricks of three distinct fly-ash to sand ratios were used, namely 50/50, 70/30 and 90/10, with varying amounts of sodium silicate (5, 10, 15, 20% by mass) and a 5% hydrated lime content.

Bagasse Ash As An Effective Replacement In Fly Ash Bricks Apurva Kulkarni1, Samruddha Raje2, Mamta Rajgor3 CHEMICAL COMPOSITION OF LIME Sr. No. Chemical Compound Lime EFFECTIVE REPLACEMENT OF FLY ASH BY BAGASSE ASH 1 SiO 2 5.39 2 A1 2O 3 (Kg) 1.06 3 Fe 2O 3 0.39 4 CaO 28.60 5 MgO 2.42 6 SO 3 0.93 SOURCE: GEO Test House, Gorwa, Gujarat d) Quarry dust …

The fly ash bricks are used more and more these days in brick masonry structures. The fly ash bricks are higher in quality and made with advanced technology. It is used as the replacement of normal clay bricks and it is better than it.

Materials used Fly Ash Lime Gypsum Quarry dust Fly ash Bricks Fig. Fly ash used is of type class C with a specific gravity of 2. Properties of Materials Fly ash Fly ash is finely divided residue resulting from the combustion of powdered coal and transported …

Bricks from Fly Ash Entrepreneur India

Bricks from Fly Ash – Manufacturing Plant, Detailed Project Report, Profile, Business plan, Industry Trends, Market research, survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment opportunities, Cost and Revenue. Introduction Fly Ash is a burnt residue of pulverized coal (bituminous or sub-bituminous) and is siliceous in nature. In past few decades, R&D

*Fly ash and other CCPs are UVCB substances (substance of unknown or variable composition or biological). Fly ash is defined by Fly ash is defined by the U.S. EPA as: “The residuum from the burning of a combination of carbonaceous materials.

from fine fly ash (Class F) and Alkaline solution, then studied the hardened properties of fly ash bricks with addition of lime and gypsum. In this paper, we have studied the composition of high -strength fly

Fly Ash brick is a product of basic cement clinker materials i.e. fly ash, stone dust/sand, lime, gypsum and bonding agent. The mix is so ideally worked out to produce bricks of higher strength with consistency as well as uniformity. The manufacturing process is fully automatic with state of art technology. Though a new age product introduced in the market, Fly Ash bricks are very well

Other innovative products such as fly ash bricks, roofing tiles, flex-crete, poly-ash, etc., may be eligible for points in this category because they are generally 70 to 100% of total product. Concrete in LEED Using concrete can influence 25 of 55 LEED v4 credits and prerequisites and may potentially contribute to as many as 74 of the 110 points, according the the National Ready Mixed Concrete

GUIDELINES FOR MANUFACTURING QUALITY FLY ASH BRICKS Prepared By Fly Ash Resource Centre, Crushed bottom fuel ash or sand is also used in the composition as a coarse material to control water absorption in the final product. Advantages of Fly Ash Bricks The advantages of fly ash brick are High compressive strength Lower water absorption Dimensional accuracy. High strength to …

Pulverized fuel ash commonly known as fly ash is a useful by-product from thermal power stations using pulverized coal as fiel and has considerable pozzolonic activity. This national resource has been gainfully utilized for manufacture of Pulverized fuel ash-lime bricks as a supplement to common burnt clay building bricks leading to conservation of natural resources and improvement in

Evaluate properties of fly ash based Geopolymer Bricks

Influence of Fly Ash on Brick Properties and the Impact of

raw material of flyash bricks YouTube

Fly Ash Bricks Composition Wholesale Brick Suppliers

Experimental Studies on Lime-Soil-Fly Ash Bricks

LIGHTWEIGHT BRICKS FROM FLY-ASH

Which is better a fly ash brick or a normal red brick

running lean ash maurya pdf – Bricks from Fly Ash entrepreneurindia.co

Bagasse Ash As An Effective Replacement In Fly Ash Bricks

ANN MODEL FOR PREDICTING THE QUALITY PARAMETERS OF FLY ASH

Fly Ash Brick (1).pdf Brick Fly Ash es.scribd.com

FLY ASH BRICKS bcef.in

Fly Ash Bricks Mixing Proportion – 3 Important Formulas

The characteristics of fly ash depend upon the quality of lignite/coal and the efficiency of boilers.a Characteristics of Fly ash The physical and chemical properties of Fly Ash are tabulated below 4. The fly ash generation in India Thermal Stations is likely to shoot up to 170 million tones in 2010 from the present level of 100 million tones. i.4.

of fly ash bricks for testing purpose to ensure the required minimum compressive strength of bricks should not be less than 5 N/sq.mm or more than 10 N/sq.mm. The water absorption is tested weighing the bricks in dry condition then by immersing the brick in water for 24 hours and weighing it thereafter. The water absorption of the bricks should not n be then dispatched to market. A. Problem

Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash The cost of fly ash brick is approximate 30%lower brick. Clay brick are uneven in shape as the mostly Uniform in shape and smooth in finish as the clay bricks are made manually.

bricks as it is 18.16% in case of normal clay bricks and it decreases to 9.60% when 40% of fly ash is added in the manufactured sample. On the other hand a reverse pattern is perceived on addition of rice husk ash instead of fly ash

Strengthening of Fly Ash Bricks By Ironite IOSR Journals

Which is better a fly ash brick or a normal red brick

F fly ash depends on the basic clay composition of coal and then, on the operating parameters of the power plants with special emphasis on combustion temperature, fineness and

composition as a coarser material to control water absorption in the final product. Pulverized fuel ash reacts with lime in presence of moisture from a calcium hydrate which is a binder material. Thus pulverized fuel ash – lime in presence of moisture form a calcium – silicate hydrate which is binder material. Thus pulverized fuel ash – lime brick is a chemically ended bricks. These

Fly Ash brick is a product of basic cement clinker materials i.e. fly ash, stone dust/sand, lime, gypsum and bonding agent. The mix is so ideally worked out to produce bricks of higher strength with consistency as well as uniformity. The manufacturing process is fully automatic with state of art technology. Though a new age product introduced in the market, Fly Ash bricks are very well

Volume mass, compressive strength, water uptake and water absorption of pressed test samples made of a mixture of coal fly-ash, slag and sodium silicate solution (water-glass) were determined.

7 Mineral composition and clay index for the samples containing fly ash, clay, and clay plus shale 6 8 Total weight loss and shrinkage for Batch 1 bricks fired at Brick Plant I 6

Fly ash contains Co 2 emitted from Thermal power plants, industries using coal as a fuel emits unwanted ash and smoke from which fly ash is produced. In all the power plants and industries, they separate the fly ash by using the cyclone converter. This fly ash is then used as …

Fly Ash bricks are an alternative for the conventional bricks which can be used effectively to replace the conventional bricks. Various properties of these bricks were studied by different researchers and they found that these bricks can be used for construction of low cost houses in the area in the vicinity of thermal power plant. This paper is an attempt to study the strength and durability

Fly ash is one of the major residues generated during combustion of coal in thermal power plants. Fly ash brick technology is Fly ash brick technology is the process of converting industrial waste material into quality building material.

The most-often-used specifications for fly ash are ASTM C 618 and AASHTO M 295.Two major classes of fly ash are specified in ASTM C 618 on the basis of their chemical composition resulting from the type of coal burned; these are designated Class F and Class C. Class F is fly ash normally 47 JOURNAL Of NUCLEAR And Related TECHNOLOGIES, Volume 4, Special Edition, 2007 produced …

and fly ash The main aim of this research was to compare the compressive strength of the bricks, so for this purpose different percentage of materials were separately added 5%, 10%, 15%,

GUIDELINES FOR MANUFACTURING QUALITY FLY ASH BRICKS Prepared By Fly Ash Resource Centre, Crushed bottom fuel ash or sand is also used in the composition as a coarse material to control water absorption in the final product. Advantages of Fly Ash Bricks The advantages of fly ash brick are High compressive strength Lower water absorption Dimensional accuracy. High strength to …

*Fly ash and other CCPs are UVCB substances (substance of unknown or variable composition or biological). Fly ash is defined by Fly ash is defined by the U.S. EPA as: “The residuum from the burning of a combination of carbonaceous materials.

WATER ABSORPTION OF FLY ASH AND RICE HUSK ASH BRICKS

fly ash bricks paper.pdf Fly Ash Lime (Material)

of fly ash bricks for testing purpose to ensure the required minimum compressive strength of bricks should not be less than 5 N/sq.mm or more than 10 N/sq.mm. The water absorption is tested weighing the bricks in dry condition then by immersing the brick in water for 24 hours and weighing it thereafter. The water absorption of the bricks should not n be then dispatched to market. A. Problem

Paper on use of Fly ash for Brick making (Clay-fly ash bricks) 1.0 Background Fly ash is a coal combustion by-product – a finely divided residue resulting from combustion of coal in power plants. In the thermal power stations, coal is pulverized into fine powder and pumped into the boiler along with compressed air. Coal powder is fired to generate heat, which in turn produces steam to run

Fly-Ash Bricks and Blocks are largely used in various constructions, such as load bearing and pillar structure Buildings, Boundary walls, Roads, Culverts, Pavements, and wherever conventional bricks can be …

F fly ash depends on the basic clay composition of coal and then, on the operating parameters of the power plants with special emphasis on combustion temperature, fineness and

Secondly for fly ash bricks were prepared by using cement and stone powder in varying proportions. Also, the bricks were prepared from flyash, lime, sand and gypsum. The bricks were prepared by using different proportions of fly ash, lime, sand and gypsum. Initially the lime was slaked with water and made it soft. The flyash was thoroughly mixed with fly ash shows cementious property. The sand

The most-often-used specifications for fly ash are ASTM C 618 and AASHTO M 295.Two major classes of fly ash are specified in ASTM C 618 on the basis of their chemical composition resulting from the type of coal burned; these are designated Class F and Class C. Class F is fly ash normally 47 JOURNAL Of NUCLEAR And Related TECHNOLOGIES, Volume 4, Special Edition, 2007 produced …

composition as a coarser material to control water absorption in the final product. Pulverized fuel ash reacts with lime in presence of moisture from a calcium hydrate which is a binder material. Thus pulverized fuel ash – lime in presence of moisture form a calcium – silicate hydrate which is binder material. Thus pulverized fuel ash – lime brick is a chemically ended bricks. These

Fly ash contains Co 2 emitted from Thermal power plants, industries using coal as a fuel emits unwanted ash and smoke from which fly ash is produced. In all the power plants and industries, they separate the fly ash by using the cyclone converter. This fly ash is then used as …

Alibaba.com offers 79 fly ash bricks composition products. About 3% of these are engineered flooring, 2% are aluminum composite panels. A wide variety of fly ash bricks composition options are available to you, such as free samples.

Fly Ash Facts for Highway Engineers (ASTM) Specification C 618] defines the chemical composition of Class C and Class F fly ash. Class C ashes are generally derived from sub-bituminous coals and consist primarily of calcium alumino-sulfate glass, as well as quartz, tricalcium aluminate, and free lime (CaO). Class C ash is also referred to as high calcium fly ash because it typically

KEYWORDS: brick, fly ash Abstract A new approach to the production of bricks was carried out by using lignite fly ash. The possibility of fly ash for use as building material was investigated. Pure fly ash and certain amount of mixing water (17.5 mass-%) were used as body composition for the production of brick …

Karthikeyan and M Ponni (3) studied the utilisation of fly ash in bricks. The fly ash can The fly ash can be effectively used for manufacture of bricks using fly-ash, lime, sand and gypsum.

Strengthening of Fly Ash Bricks By Ironite IOSR Journals

Manufacturing Bricks with Fly Ash and Advanced Coal

The building bricks contained 20, 30, or 40 vol% of fly ash from two different Illinois sources, and the paving bricks produced contained 20 vol% of fly ash from one of these two sources.

Strengthening Of Fly Ash Bricks By Ironite www.iosrjournals.org 22 Page Lime Quick Lime or hydrated lime or both can be mixed in the composition.

Raw material: the raw materials of fly ash brick mainly includes cement, slag, fly ash and other construction rubbish, but the fly ash bricks have high strength. For red bricks, they are made from clay. We can conclude that the fly ash bricks have lower cost and higher strength than the red bricks.

FLY ASH BRICKS Fly ash bricks manufacturing units can be set up nearby thermalpower stations.Because the main raw materialis fly ash is generated by thermal power stations in big quanity . Fly ash supplied by thermal power stations at free of cost the entreprenuer has to bare only transportations charges from thermalpower stations to the fly ash bricks manufacturing unit. . There …

Bagasse Ash As An Effective Replacement In Fly Ash Bricks Apurva Kulkarni1, Samruddha Raje2, Mamta Rajgor3 CHEMICAL COMPOSITION OF LIME Sr. No. Chemical Compound Lime EFFECTIVE REPLACEMENT OF FLY ASH BY BAGASSE ASH 1 SiO 2 5.39 2 A1 2O 3 (Kg) 1.06 3 Fe 2O 3 0.39 4 CaO 28.60 5 MgO 2.42 6 SO 3 0.93 SOURCE: GEO Test House, Gorwa, Gujarat d) Quarry dust …

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly. Disadvantages are, the outer surface or shell of brick is hard compared to inner core, in case a chase is cut to lay conduits and pipes, the chances of development of cracks later in the

Fly Ash brick is a product of basic cement clinker materials i.e. fly ash, stone dust/sand, lime, gypsum and bonding agent. The mix is so ideally worked out to produce bricks of higher strength with consistency as well as uniformity. The manufacturing process is fully automatic with state of art technology. Though a new age product introduced in the market, Fly Ash bricks are very well

Bricks of three distinct fly-ash to sand ratios were used, namely 50/50, 70/30 and 90/10, with varying amounts of sodium silicate (5, 10, 15, 20% by mass) and a 5% hydrated lime content.

Fly ash brick are lighter as the main composition is fly ash. Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash brick. The cost of fly ash brick is approximate 30%lower

Materials used Fly Ash Lime Gypsum Quarry dust Fly ash Bricks Fig. Fly ash used is of type class C with a specific gravity of 2. Properties of Materials Fly ash Fly ash is finely divided residue resulting from the combustion of powdered coal and transported …

Fly Ash Facts for Highway Engineers (ASTM) Specification C 618] defines the chemical composition of Class C and Class F fly ash. Class C ashes are generally derived from sub-bituminous coals and consist primarily of calcium alumino-sulfate glass, as well as quartz, tricalcium aluminate, and free lime (CaO). Class C ash is also referred to as high calcium fly ash because it typically

My house ground floor is made with red clay bricks.Now i constructed first floor with fly ash brick but in 3 to 4 months area made with fly ash have crack in plaster..the constructor says it happens in fly ash brick in summer. Is it true..if yes how to treat it.

ii strength characteristic study of fly ash composite material a thesis submitted in partial fulfillment of the requirements for the degree of

flyash bricks plant pmegp scheme ugcnetnic.in

Fly ash The resource for construction industry FAL-G

Paper on use of Fly ash for Brick making (Clay-fly ash bricks) 1.0 Background Fly ash is a coal combustion by-product – a finely divided residue resulting from combustion of coal in power plants. In the thermal power stations, coal is pulverized into fine powder and pumped into the boiler along with compressed air. Coal powder is fired to generate heat, which in turn produces steam to run

7 Mineral composition and clay index for the samples containing fly ash, clay, and clay plus shale 6 8 Total weight loss and shrinkage for Batch 1 bricks fired at Brick Plant I 6

stabilizers in unfired bricks, but people have experimented with using fly ash, rice husk ash, and other common materials to improve the quality of their bricks (Maini, 2010). Portland cement is particularly good for stabilizing bricks made from sandy soils.

Fly Ash Facts for Highway Engineers (ASTM) Specification C 618] defines the chemical composition of Class C and Class F fly ash. Class C ashes are generally derived from sub-bituminous coals and consist primarily of calcium alumino-sulfate glass, as well as quartz, tricalcium aluminate, and free lime (CaO). Class C ash is also referred to as high calcium fly ash because it typically

bricks as it is 18.16% in case of normal clay bricks and it decreases to 9.60% when 40% of fly ash is added in the manufactured sample. On the other hand a reverse pattern is perceived on addition of rice husk ash instead of fly ash

Which is better a fly ash brick or a normal red brick

SUSTAINABLE BUILDING MATERIALS FLY ASH BRICKS Pri

from fine fly ash (Class F) and Alkaline solution, then studied the hardened properties of fly ash bricks with addition of lime and gypsum. In this paper, we have studied the composition of high -strength fly

Fly Ash bricks are an alternative for the conventional bricks which can be used effectively to replace the conventional bricks. Various properties of these bricks were studied by different researchers and they found that these bricks can be used for construction of low cost houses in the area in the vicinity of thermal power plant. This paper is an attempt to study the strength and durability

Bricks from Fly Ash – Manufacturing Plant, Detailed Project Report, Profile, Business plan, Industry Trends, Market research, survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment opportunities, Cost and Revenue. Introduction Fly Ash is a burnt residue of pulverized coal (bituminous or sub-bituminous) and is siliceous in nature. In past few decades, R&D

*Fly ash and other CCPs are UVCB substances (substance of unknown or variable composition or biological). Fly ash is defined by Fly ash is defined by the U.S. EPA as: “The residuum from the burning of a combination of carbonaceous materials.

BURNTCLAY FLY ASH BUILDING BRICKS. ‘SPECIFICATION 1 SCOPE 5 GENERAL QUALITY 1.1 This standard lays down requirements for-classification, general quality, dimensions and physical requirements of common burnt clay building bricks used in buildings. NOTE – Burnt clay ftyash bricks having compres sive strength less than 30 N/mm’ approximately 300 kgf/em- are covered in this …

Secondly for fly ash bricks were prepared by using cement and stone powder in varying proportions. Also, the bricks were prepared from flyash, lime, sand and gypsum. The bricks were prepared by using different proportions of fly ash, lime, sand and gypsum. Initially the lime was slaked with water and made it soft. The flyash was thoroughly mixed with fly ash shows cementious property. The sand

Fly ash brick are lighter as the main composition is fly ash. Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash brick. The cost of fly ash brick is approximate 30%lower

Other innovative products such as fly ash bricks, roofing tiles, flex-crete, poly-ash, etc., may be eligible for points in this category because they are generally 70 to 100% of total product. Concrete in LEED Using concrete can influence 25 of 55 LEED v4 credits and prerequisites and may potentially contribute to as many as 74 of the 110 points, according the the National Ready Mixed Concrete

however, bricks made from fly ash/silica sa nd and fly ash/common sand would need dry densities of approximately 1.40 t/m 3 and 1.60 t/m 3 , respectively. Compared to dry densities of

Fly Ash Brick Technology

FEASIBILITY OF USING WASTE GLASS POWDER IN FLY ASH BRICKS

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly. Disadvantages are, the outer surface or shell of brick is hard compared to inner core, in case a chase is cut to lay conduits and pipes, the chances of development of cracks later in the

from fine fly ash (Class F) and Alkaline solution, then studied the hardened properties of fly ash bricks with addition of lime and gypsum. In this paper, we have studied the composition of high -strength fly

Fly ash brick are lighter as the main composition is fly ash. Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash brick. The cost of fly ash brick is approximate 30%lower

Pulverized fuel ash commonly known as fly ash is a useful by-product from thermal power stations using pulverized coal as fiel and has considerable pozzolonic activity. This national resource has been gainfully utilized for manufacture of Pulverized fuel ash-lime bricks as a supplement to common burnt clay building bricks leading to conservation of natural resources and improvement in

Karthikeyan and M Ponni (3) studied the utilisation of fly ash in bricks. The fly ash can The fly ash can be effectively used for manufacture of bricks using fly-ash, lime, sand and gypsum.

Bricks of three distinct fly-ash to sand ratios were used, namely 50/50, 70/30 and 90/10, with varying amounts of sodium silicate (5, 10, 15, 20% by mass) and a 5% hydrated lime content.

Raw material: the raw materials of fly ash brick mainly includes cement, slag, fly ash and other construction rubbish, but the fly ash bricks have high strength. For red bricks, they are made from clay. We can conclude that the fly ash bricks have lower cost and higher strength than the red bricks.

The fly ash bricks are used more and more these days in brick masonry structures. The fly ash bricks are higher in quality and made with advanced technology. It is used as the replacement of normal clay bricks and it is better than it.

SUSTAINABLE BUILDING MATERIALS FLY ASH BRICKS Pri

Influence of Fly Ash on Brick Properties and the Impact of

Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash The cost of fly ash brick is approximate 30%lower brick. Clay brick are uneven in shape as the mostly Uniform in shape and smooth in finish as the clay bricks are made manually.

Strengthening Of Fly Ash Bricks By Ironite www.iosrjournals.org 22 Page Lime Quick Lime or hydrated lime or both can be mixed in the composition.

Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash The cost of fly ash brick is approximate 30%lower brick. plastering required in normal cases. But this can be improved by adding marble/ stone dust and cementing materials. Fly ash brick are lighter as the main composition is fly ash. 3. Only modular size can be produced.Demerit of Fly Ash

9/01/2016 · Dear sir, Enjoy your day! With the latest technologies through planning and development, we, “prem nath & brothers”, have carved a valuable niche for our products across the globe.

ii strength characteristic study of fly ash composite material a thesis submitted in partial fulfillment of the requirements for the degree of

A New Approach to the Production of Bricks Made Fly Ash

Fly Ash Bricks Composition Wholesale Brick Suppliers

Materials used Fly Ash Lime Gypsum Quarry dust Fly ash Bricks Fig. Fly ash used is of type class C with a specific gravity of 2. Properties of Materials Fly ash Fly ash is finely divided residue resulting from the combustion of powdered coal and transported …

7 Mineral composition and clay index for the samples containing fly ash, clay, and clay plus shale 6 8 Total weight loss and shrinkage for Batch 1 bricks fired at Brick Plant I 6

Raw material: the raw materials of fly ash brick mainly includes cement, slag, fly ash and other construction rubbish, but the fly ash bricks have high strength. For red bricks, they are made from clay. We can conclude that the fly ash bricks have lower cost and higher strength than the red bricks.

Fly Ash Brick (1).pdf Brick – Scribd – Read books Clay brick are uneven in shape as the mostly Uniform in shape and smooth in finish as the clay bricks are made manually.Air exchange is poor in comparison to normal clay bricks. soil.

Fly Ash Facts for Highway Engineers (ASTM) Specification C 618] defines the chemical composition of Class C and Class F fly ash. Class C ashes are generally derived from sub-bituminous coals and consist primarily of calcium alumino-sulfate glass, as well as quartz, tricalcium aluminate, and free lime (CaO). Class C ash is also referred to as high calcium fly ash because it typically

from fine fly ash (Class F) and Alkaline solution, then studied the hardened properties of fly ash bricks with addition of lime and gypsum. In this paper, we have studied the composition of high -strength fly

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly. Disadvantages are, the outer surface or shell of brick is hard compared to inner core, in case a chase is cut to lay conduits and pipes, the chances of development of cracks later in the

Fly ash brick are lighter as the main composition is fly ash. Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash brick. The cost of fly ash brick is approximate 30%lower

The most-often-used specifications for fly ash are ASTM C 618 and AASHTO M 295.Two major classes of fly ash are specified in ASTM C 618 on the basis of their chemical composition resulting from the type of coal burned; these are designated Class F and Class C. Class F is fly ash normally 47 JOURNAL Of NUCLEAR And Related TECHNOLOGIES, Volume 4, Special Edition, 2007 produced …

stabilizers in unfired bricks, but people have experimented with using fly ash, rice husk ash, and other common materials to improve the quality of their bricks (Maini, 2010). Portland cement is particularly good for stabilizing bricks made from sandy soils.

Fly ash is one of the major residues generated during combustion of coal in thermal power plants. Fly ash brick technology is Fly ash brick technology is the process of converting industrial waste material into quality building material.

(PDF) Development of low-cost fly ash bricks ResearchGate

Fly Ash Brick (1).pdf Brick Fly Ash es.scribd.com

Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash The cost of fly ash brick is approximate 30%lower brick. Clay brick are uneven in shape as the mostly Uniform in shape and smooth in finish as the clay bricks are made manually.

Raw material: the raw materials of fly ash brick mainly includes cement, slag, fly ash and other construction rubbish, but the fly ash bricks have high strength. For red bricks, they are made from clay. We can conclude that the fly ash bricks have lower cost and higher strength than the red bricks.

KEYWORDS: brick, fly ash Abstract A new approach to the production of bricks was carried out by using lignite fly ash. The possibility of fly ash for use as building material was investigated. Pure fly ash and certain amount of mixing water (17.5 mass-%) were used as body composition for the production of brick …

F fly ash depends on the basic clay composition of coal and then, on the operating parameters of the power plants with special emphasis on combustion temperature, fineness and

silica) in the fly ash varies depending on the quartz content of the coal. Class C fly ash may have 1-7% Class C fly ash may have 1-7% free CaO and calcium sulfate as well as calcium aluminosilicate glass.

ash is composed of the non-combustible mineral portion of coal consumed in a coal fuelled power plant.Fly ash is a powdery substance obtained from the dust collectors in …

(PDF) Development of low-cost fly ash bricks ResearchGate

Experimental Studies on Lime-Soil-Fly Ash Bricks

however, bricks made from fly ash/silica sa nd and fly ash/common sand would need dry densities of approximately 1.40 t/m 3 and 1.60 t/m 3 , respectively. Compared to dry densities of

Secondly for fly ash bricks were prepared by using cement and stone powder in varying proportions. Also, the bricks were prepared from flyash, lime, sand and gypsum. The bricks were prepared by using different proportions of fly ash, lime, sand and gypsum. Initially the lime was slaked with water and made it soft. The flyash was thoroughly mixed with fly ash shows cementious property. The sand

stabilizers in unfired bricks, but people have experimented with using fly ash, rice husk ash, and other common materials to improve the quality of their bricks (Maini, 2010). Portland cement is particularly good for stabilizing bricks made from sandy soils.

Fly ash contains Co 2 emitted from Thermal power plants, industries using coal as a fuel emits unwanted ash and smoke from which fly ash is produced. In all the power plants and industries, they separate the fly ash by using the cyclone converter. This fly ash is then used as a raw material for manufacture of bricks.

Karthikeyan and M Ponni (3) studied the utilisation of fly ash in bricks. The fly ash can The fly ash can be effectively used for manufacture of bricks using fly-ash, lime, sand and gypsum.

Fly Ash brick is a product of basic cement clinker materials i.e. fly ash, stone dust/sand, lime, gypsum and bonding agent. The mix is so ideally worked out to produce bricks of higher strength with consistency as well as uniformity. The manufacturing process is fully automatic with state of art technology. Though a new age product introduced in the market, Fly Ash bricks are very well

The properties of fly ash bricks depend mainly on two factors: ) the energy content of the fly ash used and 1 ) 2 the chemical composition of the fly ash. Table 1 shows the chemical composition of fly ash from two different

Raw material: the raw materials of fly ash brick mainly includes cement, slag, fly ash and other construction rubbish, but the fly ash bricks have high strength. For red bricks, they are made from clay. We can conclude that the fly ash bricks have lower cost and higher strength than the red bricks.

GUIDELINES FOR MANUFACTURING QUALITY FLY ASH BRICKS Prepared By Fly Ash Resource Centre, Crushed bottom fuel ash or sand is also used in the composition as a coarse material to control water absorption in the final product. Advantages of Fly Ash Bricks The advantages of fly ash brick are High compressive strength Lower water absorption Dimensional accuracy. High strength to …

The characteristics of fly ash depend upon the quality of lignite/coal and the efficiency of boilers.a Characteristics of Fly ash The physical and chemical properties of Fly Ash are tabulated below 4. The fly ash generation in India Thermal Stations is likely to shoot up to 170 million tones in 2010 from the present level of 100 million tones. i.4.

from fine fly ash (Class F) and Alkaline solution, then studied the hardened properties of fly ash bricks with addition of lime and gypsum. In this paper, we have studied the composition of high -strength fly

Fly Ash Brick (1).pdf Brick Scribd – Read books

Experimental Studies on Lime-Soil-Fly Ash Bricks

BURNTCLAY FLY ASH BUILDING BRICKS. ‘SPECIFICATION 1 SCOPE 5 GENERAL QUALITY 1.1 This standard lays down requirements for-classification, general quality, dimensions and physical requirements of common burnt clay building bricks used in buildings. NOTE – Burnt clay ftyash bricks having compres sive strength less than 30 N/mm’ approximately 300 kgf/em- are covered in this …

Fly ash is one of the major residues generated during combustion of coal in thermal power plants. Fly ash brick technology is Fly ash brick technology is the process of converting industrial waste material into quality building material.

Fly Ash brick is a product of basic cement clinker materials i.e. fly ash, stone dust/sand, lime, gypsum and bonding agent. The mix is so ideally worked out to produce bricks of higher strength with consistency as well as uniformity. The manufacturing process is fully automatic with state of art technology. Though a new age product introduced in the market, Fly Ash bricks are very well

Based on Fly-ash bricks and clay bricks the data collected, Data will be collected through questionnaires and personal interviews targeting residential building and infrastructure projects. We can easily able to analysis of fly

Fly ash contains Co 2 emitted from Thermal power plants, industries using coal as a fuel emits unwanted ash and smoke from which fly ash is produced. In all the power plants and industries, they separate the fly ash by using the cyclone converter. This fly ash is then used as …

bricks as it is 18.16% in case of normal clay bricks and it decreases to 9.60% when 40% of fly ash is added in the manufactured sample. On the other hand a reverse pattern is perceived on addition of rice husk ash instead of fly ash

Strengthening Of Fly Ash Bricks By Ironite www.iosrjournals.org 22 Page Lime Quick Lime or hydrated lime or both can be mixed in the composition.

The characteristics of fly ash depend upon the quality of lignite/coal and the efficiency of boilers.a Characteristics of Fly ash The physical and chemical properties of Fly Ash are tabulated below 4. The fly ash generation in India Thermal Stations is likely to shoot up to 170 million tones in 2010 from the present level of 100 million tones. i.4.

Pulverized fuel ash commonly known as fly ash is a useful by-product from thermal power stations using pulverized coal as fiel and has considerable pozzolonic activity. This national resource has been gainfully utilized for manufacture of Pulverized fuel ash-lime bricks as a supplement to common burnt clay building bricks leading to conservation of natural resources and improvement in

Experimental Studies on Lime-Soil-Fly Ash Bricks

STRENGTH CHARACTERISTIC STUDY OF FLY ASH ethesis

7 Mineral composition and clay index for the samples containing fly ash, clay, and clay plus shale 6 8 Total weight loss and shrinkage for Batch 1 bricks fired at Brick Plant I 6

Raw material: the raw materials of fly ash brick mainly includes cement, slag, fly ash and other construction rubbish, but the fly ash bricks have high strength. For red bricks, they are made from clay. We can conclude that the fly ash bricks have lower cost and higher strength than the red bricks.

bricks as it is 18.16% in case of normal clay bricks and it decreases to 9.60% when 40% of fly ash is added in the manufactured sample. On the other hand a reverse pattern is perceived on addition of rice husk ash instead of fly ash

KEYWORDS: brick, fly ash Abstract A new approach to the production of bricks was carried out by using lignite fly ash. The possibility of fly ash for use as building material was investigated. Pure fly ash and certain amount of mixing water (17.5 mass-%) were used as body composition for the production of brick …

The building bricks contained 20, 30, or 40 vol% of fly ash from two different Illinois sources, and the paving bricks produced contained 20 vol% of fly ash from one of these two sources.

The characteristics of fly ash depend upon the quality of lignite/coal and the efficiency of boilers.a Characteristics of Fly ash The physical and chemical properties of Fly Ash are tabulated below 4. The fly ash generation in India Thermal Stations is likely to shoot up to 170 million tones in 2010 from the present level of 100 million tones. i.4.

Fly ash is one of the major residues generated during combustion of coal in thermal power plants. Fly ash brick technology is Fly ash brick technology is the process of converting industrial waste material into quality building material.

Fly Ash bricks are an alternative for the conventional bricks which can be used effectively to replace the conventional bricks. Various properties of these bricks were studied by different researchers and they found that these bricks can be used for construction of low cost houses in the area in the vicinity of thermal power plant. This paper is an attempt to study the strength and durability

Secondly for fly ash bricks were prepared by using cement and stone powder in varying proportions. Also, the bricks were prepared from flyash, lime, sand and gypsum. The bricks were prepared by using different proportions of fly ash, lime, sand and gypsum. Initially the lime was slaked with water and made it soft. The flyash was thoroughly mixed with fly ash shows cementious property. The sand

A fly ash composition is provided which includes an amount of lithium carbonate to reduce alkali silica reactivity when the fly ash composition is used in concrete applications. The fly ash composition includes from about 0.5 wt.% to about 98% wt.% subbituminous fly ash and from about 0.5 wt.% to about 3 wt.% lithium carbonate.

silica) in the fly ash varies depending on the quartz content of the coal. Class C fly ash may have 1-7% Class C fly ash may have 1-7% free CaO and calcium sulfate as well as calcium aluminosilicate glass.

Based on Fly-ash bricks and clay bricks the data collected, Data will be collected through questionnaires and personal interviews targeting residential building and infrastructure projects. We can easily able to analysis of fly

My house ground floor is made with red clay bricks.Now i constructed first floor with fly ash brick but in 3 to 4 months area made with fly ash have crack in plaster..the constructor says it happens in fly ash brick in summer. Is it true..if yes how to treat it.

TE fly ash brochure

Fly Ash Bricks Mixing Proportion – 3 Important Formulas

FLY ASH BRICKS Fly ash bricks manufacturing units can be set up nearby thermalpower stations.Because the main raw materialis fly ash is generated by thermal power stations in big quanity . Fly ash supplied by thermal power stations at free of cost the entreprenuer has to bare only transportations charges from thermalpower stations to the fly ash bricks manufacturing unit. . There …

Fly ash bricks were studied by R.L. Day and et al. [2] they used fly ash from western Canada as a main composition up to 70-100% mixed with bottom ash and NaOH, Na 2 CO 3 or Na 2 SiO 3 were added for better solidity of brick samples.

My house ground floor is made with red clay bricks.Now i constructed first floor with fly ash brick but in 3 to 4 months area made with fly ash have crack in plaster..the constructor says it happens in fly ash brick in summer. Is it true..if yes how to treat it.

bricks as it is 18.16% in case of normal clay bricks and it decreases to 9.60% when 40% of fly ash is added in the manufactured sample. On the other hand a reverse pattern is perceived on addition of rice husk ash instead of fly ash

Fly Ash Bricks Fly Ash Brick pt.scribd.com

Fly Ash Brick Technology

Materials used Fly Ash Lime Gypsum Quarry dust Fly ash Bricks Fig. Fly ash used is of type class C with a specific gravity of 2. Properties of Materials Fly ash Fly ash is finely divided residue resulting from the combustion of powdered coal and transported …

Fly ash brick are lighter as the main composition is fly ash. Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash brick. The cost of fly ash brick is approximate 30%lower

The most-often-used specifications for fly ash ar e ASTM C 618 and AASH TO M 295.Two major classes of fly ash are specified in ASTM C 618 on the basis of their chemical composition …

Fly-Ash Bricks and Blocks are largely used in various constructions, such as load bearing and pillar structure Buildings, Boundary walls, Roads, Culverts, Pavements, and wherever conventional bricks can be …

however, bricks made from fly ash/silica sa nd and fly ash/common sand would need dry densities of approximately 1.40 t/m 3 and 1.60 t/m 3 , respectively. Compared to dry densities of

Strength and Durability of Fly Ash Cement and Gypsum Bricks

pd fly ash bricks composition lunastrumsv.nl

BURNTCLAY FLY ASH BUILDING BRICKS. ‘SPECIFICATION 1 SCOPE 5 GENERAL QUALITY 1.1 This standard lays down requirements for-classification, general quality, dimensions and physical requirements of common burnt clay building bricks used in buildings. NOTE – Burnt clay ftyash bricks having compres sive strength less than 30 N/mm’ approximately 300 kgf/em- are covered in this …

Fly ash bricks are lighter as the main composition is fly ash. Clay bricks are heavier as compared to fly ash bricks. Fly ash bricks are less porous. Clay bricks are more porous. The cost of fly ash brick is approximate 30% lower than clay brick. The cost of clay brick is higher than fly ash brick. This is made by using by-product of Thermal Power Plant, which save environment from being

Bricks from Fly Ash – Manufacturing Plant, Detailed Project Report, Profile, Business plan, Industry Trends, Market research, survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment opportunities, Cost and Revenue. Introduction Fly Ash is a burnt residue of pulverized coal (bituminous or sub-bituminous) and is siliceous in nature. In past few decades, R&D

Secondly for fly ash bricks were prepared by using cement and stone powder in varying proportions. Also, the bricks were prepared from flyash, lime, sand and gypsum. The bricks were prepared by using different proportions of fly ash, lime, sand and gypsum. Initially the lime was slaked with water and made it soft. The flyash was thoroughly mixed with fly ash shows cementious property. The sand

Raw material: the raw materials of fly ash brick mainly includes cement, slag, fly ash and other construction rubbish, but the fly ash bricks have high strength. For red bricks, they are made from clay. We can conclude that the fly ash bricks have lower cost and higher strength than the red bricks.

GUIDELINES FOR MANUFACTURING QUALITY FLY ASH BRICKS Prepared By Fly Ash Resource Centre, Crushed bottom fuel ash or sand is also used in the composition as a coarse material to control water absorption in the final product. Advantages of Fly Ash Bricks The advantages of fly ash brick are High compressive strength Lower water absorption Dimensional accuracy. High strength to …

stabilizers in unfired bricks, but people have experimented with using fly ash, rice husk ash, and other common materials to improve the quality of their bricks (Maini, 2010). Portland cement is particularly good for stabilizing bricks made from sandy soils.

FEASIBILITY OF USING WASTE GLASS POWDER IN FLY ASH BRICKS

Fly Ash Facts for Highway Engineers (ASTM) Specification C 618] defines the chemical composition of Class C and Class F fly ash. Class C ashes are generally derived from sub-bituminous coals and consist primarily of calcium alumino-sulfate glass, as well as quartz, tricalcium aluminate, and free lime (CaO). Class C ash is also referred to as high calcium fly ash because it typically

US6251178B1 Fly ash composition – Google Patents

Fly Ash Bricks and Comparison with Clay Bricks

Fly Ash Bricks Fly Ash Brick pt.scribd.com

Materials used Fly Ash Lime Gypsum Quarry dust Fly ash Bricks Fig. Fly ash used is of type class C with a specific gravity of 2. Properties of Materials Fly ash Fly ash is finely divided residue resulting from the combustion of powdered coal and transported …

fly ash bricks paper.pdf Fly Ash Lime (Material)

Strength and Durability of Fly Ash Cement and Gypsum Bricks

Assessment of suitability of Fly Ash and Rice Husk Ash

COMPARISON BETWEEN FLY ASH BRICKS AND CLAY BRICKS NORMAL CLAY BRICKS FLY ASH BRICKS Varying colour as per soil Uniform pleasing colour like cement Uneven shape as hand made Uniform in shape and smooth in finish Lightly bonded Dense composition Plastering required No plastering required Heavier in weight Lighter in weight Compressive strength is around 35 Kg/cm2 …

Fly Ash Brick (1).pdf Brick Scribd – Read books

A fly ash composition is provided which includes an amount of lithium carbonate to reduce alkali silica reactivity when the fly ash composition is used in concrete applications. The fly ash composition includes from about 0.5 wt.% to about 98% wt.% subbituminous fly ash and from about 0.5 wt.% to about 3 wt.% lithium carbonate.

Bricks made of coal fly-ash and slag cured in the open

Experimental Studies on Lime-Soil-Fly Ash Bricks

My house ground floor is made with red clay bricks.Now i constructed first floor with fly ash brick but in 3 to 4 months area made with fly ash have crack in plaster..the constructor says it happens in fly ash brick in summer. Is it true..if yes how to treat it.

ANN MODEL FOR PREDICTING THE QUALITY PARAMETERS OF FLY ASH

Fly ash bricks are lighter as the main composition is fly ash. Clay bricks are heavier as compared to fly ash bricks. Fly ash bricks are less porous. Clay bricks are more porous. The cost of fly ash brick is approximate 30% lower than clay brick. The cost of clay brick is higher than fly ash brick. This is made by using by-product of Thermal Power Plant, which save environment from being

Bagasse Ash As An Effective Replacement In Fly Ash Bricks

Fly Ash Bricks and Comparison with Clay Bricks

Strengthening Of Fly Ash Bricks By Ironite http://www.iosrjournals.org 22 Page Lime Quick Lime or hydrated lime or both can be mixed in the composition.

raw material of flyash bricks YouTube

Bricks from Fly Ash entrepreneurindia.co

Directors: C.D Billett, M.F.Hovy, A. Thedvall MATERIAL SAFETY DATA SHEET FLY ASH Aug 2011 1. IDENTIFICATION OF MATERIAL Identity: Classified Fly Ash or Unclassified Fly Ash

Fly Ash Brick (1).pdf Brick Scribd – Read books

BURNTCLAY FLY ASH BUILDING BRICKS. ‘SPECIFICATION 1 SCOPE 5 GENERAL QUALITY 1.1 This standard lays down requirements for-classification, general quality, dimensions and physical requirements of common burnt clay building bricks used in buildings. NOTE – Burnt clay ftyash bricks having compres sive strength less than 30 N/mm’ approximately 300 kgf/em- are covered in this …

(PDF) Development of low-cost fly ash bricks ResearchGate

High Performance Bricks from Fly Ash . Obada Kayali. 1 . 1. School of Aerospace, Civil and Mechanical Engineering, University of New South Wales at The Australian Defence Force …

US6251178B1 Fly ash composition – Google Patents

Strengthening of Fly Ash Bricks By Ironite IOSR Journals

Bricks made of coal fly-ash and slag cured in the open

Bricks of three distinct fly-ash to sand ratios were used, namely 50/50, 70/30 and 90/10, with varying amounts of sodium silicate (5, 10, 15, 20% by mass) and a 5% hydrated lime content.

Manufacturing Bricks with Fly Ash and Advanced Coal

A New Approach to the Production of Bricks Made Fly Ash

Bricks of three distinct fly-ash to sand ratios were used, namely 50/50, 70/30 and 90/10, with varying amounts of sodium silicate (5, 10, 15, 20% by mass) and a 5% hydrated lime content.

Fly Ash Bricks Fly Ash Brick pt.scribd.com

Bricks made of coal fly-ash and slag cured in the open

Fly ash The resource for construction industry FAL-G

COMPARISON BETWEEN FLY ASH BRICKS AND CLAY BRICKS NORMAL CLAY BRICKS FLY ASH BRICKS Varying colour as per soil Uniform pleasing colour like cement Uneven shape as hand made Uniform in shape and smooth in finish Lightly bonded Dense composition Plastering required No plastering required Heavier in weight Lighter in weight Compressive strength is around 35 Kg/cm2 …

Paper on use of Fly ash for Brick making (Clay-fly ash

pd fly ash bricks composition lunastrumsv.nl

F fly ash depends on the basic clay composition of coal and then, on the operating parameters of the power plants with special emphasis on combustion temperature, fineness and

Strength and Durability of Fly Ash Cement and Gypsum Bricks

US6251178B1 Fly ash composition – Google Patents

I Fired Bricks from Fly Ash Illinois IDEALS Home

Use of Fly Ash Brick: Fly Ash Bricks can be used as replacement of common burnt clay building bricks. Market Price: As per the analysis of SOR item no.per 1000 brick + freight in Lucknow (U. compact and uniform in shape.Office building construction by Greater Noida Development Authority . Faridabad in Haryana and Talchar – Kaniha in Orissa .

Fly Ash Bricks and Comparison with Clay Bricks

ANN MODEL FOR PREDICTING THE QUALITY PARAMETERS OF FLY ASH

silica) in the fly ash varies depending on the quartz content of the coal. Class C fly ash may have 1-7% Class C fly ash may have 1-7% free CaO and calcium sulfate as well as calcium aluminosilicate glass.

SUSTAINABLE BUILDING MATERIALS FLY ASH BRICKS Pri

I Fired Bricks from Fly Ash Illinois IDEALS Home

The advantages of using fly ash brick are, the bricks carries good compressive strength, provide better thermal insulation than red clay bricks, cheaper compared to clay bricks and are environment friendly. Disadvantages are, the outer surface or shell of brick is hard compared to inner core, in case a chase is cut to lay conduits and pipes, the chances of development of cracks later in the

Fly Ash Bricks Mixing Proportion – 3 Important Formulas

(PDF) Development of low-cost fly ash bricks ResearchGate

Paper on use of Fly ash for Brick making (Clay-fly ash bricks) 1.0 Background Fly ash is a coal combustion by-product – a finely divided residue resulting from combustion of coal in power plants. In the thermal power stations, coal is pulverized into fine powder and pumped into the boiler along with compressed air. Coal powder is fired to generate heat, which in turn produces steam to run

Fly Ash Bricks and Comparison with Clay Bricks

Influence of Fly Ash on Brick Properties and the Impact of

(PDF) Development of low-cost fly ash bricks ResearchGate

however, bricks made from fly ash/silica sa nd and fly ash/common sand would need dry densities of approximately 1.40 t/m 3 and 1.60 t/m 3 , respectively. Compared to dry densities of

Fly Ash Brick (1).pdf Brick Fly Ash es.scribd.com

Fly ash The resource for construction industry FAL-G

Paper on use of Fly ash for Brick making (Clay-fly ash

Secondly for fly ash bricks were prepared by using cement and stone powder in varying proportions. Also, the bricks were prepared from flyash, lime, sand and gypsum. The bricks were prepared by using different proportions of fly ash, lime, sand and gypsum. Initially the lime was slaked with water and made it soft. The flyash was thoroughly mixed with fly ash shows cementious property. The sand

(PDF) Development of low-cost fly ash bricks ResearchGate

Fly Ash Bricks Fly Ash Brick pt.scribd.com

Fly Ash Bricks Composition Wholesale Brick Suppliers

Fly Ash Facts for Highway Engineers (ASTM) Specification C 618] defines the chemical composition of Class C and Class F fly ash. Class C ashes are generally derived from sub-bituminous coals and consist primarily of calcium alumino-sulfate glass, as well as quartz, tricalcium aluminate, and free lime (CaO). Class C ash is also referred to as high calcium fly ash because it typically

A New Approach to the Production of Bricks Made Fly Ash

I Fired Bricks from Fly Ash Illinois IDEALS Home

Fly-Ash Bricks and Blocks are largely used in various constructions, such as load bearing and pillar structure Buildings, Boundary walls, Roads, Culverts, Pavements, and wherever conventional bricks can be …

Bagasse Ash As An Effective Replacement In Fly Ash Bricks

Fly Ash Brick (1).pdf Brick Scribd – Read books

raw material of flyash bricks YouTube

Fly ash is one of the major residues generated during combustion of coal in thermal power plants. Fly ash brick technology is Fly ash brick technology is the process of converting industrial waste material into quality building material.

Bagasse Ash As An Effective Replacement In Fly Ash Bricks

Assessment of suitability of Fly Ash and Rice Husk Ash

KEYWORDS: brick, fly ash Abstract A new approach to the production of bricks was carried out by using lignite fly ash. The possibility of fly ash for use as building material was investigated. Pure fly ash and certain amount of mixing water (17.5 mass-%) were used as body composition for the production of brick …

GUIDELINES FOR MANUFACTURING QUALITY FLY ASH BRICKS

Fly Ash Brick 09.07.14 Indian Railway

A New Approach to the Production of Bricks Made Fly Ash

F fly ash depends on the basic clay composition of coal and then, on the operating parameters of the power plants with special emphasis on combustion temperature, fineness and

flyash bricks plant pmegp scheme ugcnetnic.in

raw material of flyash bricks YouTube

Fly Ash Brick (1).pdf Brick – Scribd – Read books Clay brick are uneven in shape as the mostly Uniform in shape and smooth in finish as the clay bricks are made manually.Air exchange is poor in comparison to normal clay bricks. soil.

Fly Ash Brick (1).pdf Brick Scribd – Read books

Fly ash The resource for construction industry FAL-G

Which is better a fly ash brick or a normal red brick

The most-often-used specifications for fly ash are ASTM C 618 and AASHTO M 295.Two major classes of fly ash are specified in ASTM C 618 on the basis of their chemical composition resulting from the type of coal burned; these are designated Class F and Class C. Class F is fly ash normally 47 JOURNAL Of NUCLEAR And Related TECHNOLOGIES, Volume 4, Special Edition, 2007 produced …

FEASIBILITY OF USING WASTE GLASS POWDER IN FLY ASH BRICKS

The fly ash bricks are used more and more these days in brick masonry structures. The fly ash bricks are higher in quality and made with advanced technology. It is used as the replacement of normal clay bricks and it is better than it.

flyash bricks plant pmegp scheme ugcnetnic.in

9/01/2016 · Dear sir, Enjoy your day! With the latest technologies through planning and development, we, “prem nath & brothers”, have carved a valuable niche for our products across the globe.

Paper on use of Fly ash for Brick making (Clay-fly ash

Bricks from Fly Ash Entrepreneur India

The most-often-used specifications for fly ash are ASTM C 618 and AASHTO M 295.Two major classes of fly ash are specified in ASTM C 618 on the basis of their chemical composition resulting from the type of coal burned; these are designated Class F and Class C. Class F is fly ash normally 47 JOURNAL Of NUCLEAR And Related TECHNOLOGIES, Volume 4, Special Edition, 2007 produced …

IS 12894 (2002) Pulverized Fuel Ash-Lime Bricks

A New Approach to the Production of Bricks Made Fly Ash

BURNTCLAY FLY ASH BUILDING BRICKS. ‘SPECIFICATION 1 SCOPE 5 GENERAL QUALITY 1.1 This standard lays down requirements for-classification, general quality, dimensions and physical requirements of common burnt clay building bricks used in buildings. NOTE – Burnt clay ftyash bricks having compres sive strength less than 30 N/mm’ approximately 300 kgf/em- are covered in this …

Assessment of suitability of Fly Ash and Rice Husk Ash

raw material of flyash bricks YouTube

Fly Ash Bricks Composition Wholesale Brick Suppliers

Pulverized fuel ash commonly known as fly ash is a useful by-product from thermal power stations using pulverized coal as fiel and has considerable pozzolonic activity. This national resource has been gainfully utilized for manufacture of Pulverized fuel ash-lime bricks as a supplement to common burnt clay building bricks leading to conservation of natural resources and improvement in

TE fly ash brochure

Fly Ash bricks are an alternative for the conventional bricks which can be used effectively to replace the conventional bricks. Various properties of these bricks were studied by different researchers and they found that these bricks can be used for construction of low cost houses in the area in the vicinity of thermal power plant. This paper is an attempt to study the strength and durability

LIGHTWEIGHT BRICKS FROM FLY-ASH

Fly ash bricks are lighter as the main composition is fly ash. Clay bricks are heavier as compared to fly ash bricks. Fly ash bricks are less porous. Clay bricks are more porous. The cost of fly ash brick is approximate 30% lower than clay brick. The cost of clay brick is higher than fly ash brick. This is made by using by-product of Thermal Power Plant, which save environment from being

Fly Ash Brick 09.07.14 Indian Railway

Fly ash bricks are lighter as the main composition is fly ash. Clay bricks are heavier as compared to fly ash bricks. Fly ash bricks are less porous. Clay bricks are more porous. The cost of fly ash brick is approximate 30% lower than clay brick. The cost of clay brick is higher than fly ash brick. This is made by using by-product of Thermal Power Plant, which save environment from being

LIGHTWEIGHT BRICKS FROM FLY-ASH

Fly ash The resource for construction industry FAL-G

Fly Ash Brick Technology

The most-often-used specifications for fly ash are ASTM C 618 and AASHTO M 295.Two major classes of fly ash are specified in ASTM C 618 on the basis of their chemical composition resulting from the type of coal burned; these are designated Class F and Class C. Class F is fly ash normally 47 JOURNAL Of NUCLEAR And Related TECHNOLOGIES, Volume 4, Special Edition, 2007 produced …

flyash bricks plant pmegp scheme ugcnetnic.in

pd fly ash bricks composition lunastrumsv.nl

raw material of flyash bricks YouTube

The most-often-used specifications for fly ash ar e ASTM C 618 and AASH TO M 295.Two major classes of fly ash are specified in ASTM C 618 on the basis of their chemical composition …

Fly Ash Bricks Mixing Proportion – 3 Important Formulas

Bricks from Fly Ash entrepreneurindia.co

Fly Ash Bricks and Comparison with Clay Bricks

A fly ash composition is provided which includes an amount of lithium carbonate to reduce alkali silica reactivity when the fly ash composition is used in concrete applications. The fly ash composition includes from about 0.5 wt.% to about 98% wt.% subbituminous fly ash and from about 0.5 wt.% to about 3 wt.% lithium carbonate.

Manufacturing Bricks with Fly Ash and Advanced Coal

F fly ash depends on the basic clay composition of coal and then, on the operating parameters of the power plants with special emphasis on combustion temperature, fineness and

High Capacity Fly Ash Bricks & Blocks Unit dongyue

IS 12894 (2002) Pulverized Fuel Ash-Lime Bricks

Paper on use of Fly ash for Brick making (Clay-fly ash

however, bricks made from fly ash/silica sa nd and fly ash/common sand would need dry densities of approximately 1.40 t/m 3 and 1.60 t/m 3 , respectively. Compared to dry densities of

Fly Ash Brick (1).pdf Brick Scribd – Read books

Volume mass, compressive strength, water uptake and water absorption of pressed test samples made of a mixture of coal fly-ash, slag and sodium silicate solution (water-glass) were determined.

GUIDELINES FOR MANUFACTURING QUALITY FLY ASH BRICKS

of fly ash bricks for testing purpose to ensure the required minimum compressive strength of bricks should not be less than 5 N/sq.mm or more than 10 N/sq.mm. The water absorption is tested weighing the bricks in dry condition then by immersing the brick in water for 24 hours and weighing it thereafter. The water absorption of the bricks should not n be then dispatched to market. A. Problem

Evaluate properties of fly ash based Geopolymer Bricks

Paper on use of Fly ash for Brick making (Clay-fly ash bricks) 1.0 Background Fly ash is a coal combustion by-product – a finely divided residue resulting from combustion of coal in power plants. In the thermal power stations, coal is pulverized into fine powder and pumped into the boiler along with compressed air. Coal powder is fired to generate heat, which in turn produces steam to run

Evaluate properties of fly ash based Geopolymer Bricks

Fly Ash bricks are an alternative for the conventional bricks which can be used effectively to replace the conventional bricks. Various properties of these bricks were studied by different researchers and they found that these bricks can be used for construction of low cost houses in the area in the vicinity of thermal power plant. This paper is an attempt to study the strength and durability

SUSTAINABLE BUILDING MATERIALS FLY ASH BRICKS Pri

LIGHTWEIGHT BRICKS FROM FLY-ASH

Directors: C.D Billett, M.F.Hovy, A. Thedvall MATERIAL SAFETY DATA SHEET FLY ASH Aug 2011 1. IDENTIFICATION OF MATERIAL Identity: Classified Fly Ash or Unclassified Fly Ash

Paper on use of Fly ash for Brick making (Clay-fly ash

Fly ash contains Co 2 emitted from Thermal power plants, industries using coal as a fuel emits unwanted ash and smoke from which fly ash is produced. In all the power plants and industries, they separate the fly ash by using the cyclone converter. This fly ash is then used as a raw material for manufacture of bricks.

Bricks from Fly Ash Entrepreneur India

The characteristics of fly ash depend upon the quality of lignite/coal and the efficiency of boilers.a Characteristics of Fly ash The physical and chemical properties of Fly Ash are tabulated below 4. The fly ash generation in India Thermal Stations is likely to shoot up to 170 million tones in 2010 from the present level of 100 million tones. i.4.

What are the pros and cons of fly ash bricks? Quora

COMPARISON BETWEEN FLY ASH BRICKS AND CLAY BRICKS NORMAL CLAY BRICKS FLY ASH BRICKS Varying colour as per soil Uniform pleasing colour like cement Uneven shape as hand made Uniform in shape and smooth in finish Lightly bonded Dense composition Plastering required No plastering required Heavier in weight Lighter in weight Compressive strength is around 35 Kg/cm2 …

Which is better a fly ash brick or a normal red brick

US6251178B1 Fly ash composition – Google Patents

FLY ASH BRICKS bcef.in

bricks as it is 18.16% in case of normal clay bricks and it decreases to 9.60% when 40% of fly ash is added in the manufactured sample. On the other hand a reverse pattern is perceived on addition of rice husk ash instead of fly ash

Bricks made of coal fly-ash and slag cured in the open

Bagasse Ash As An Effective Replacement In Fly Ash Bricks

raw material of flyash bricks YouTube

The most-often-used specifications for fly ash ar e ASTM C 618 and AASH TO M 295.Two major classes of fly ash are specified in ASTM C 618 on the basis of their chemical composition …

FLY ASH BRICKS bcef.in

(PDF) Development of low-cost fly ash bricks ResearchGate

Fly ash bricks are lighter as the main composition is fly ash. Clay bricks are heavier as compared to fly ash bricks. Fly ash bricks are less porous. Clay bricks are more porous. The cost of fly ash brick is approximate 30% lower than clay brick. The cost of clay brick is higher than fly ash brick. This is made by using by-product of Thermal Power Plant, which save environment from being

Fly Ash Bricks Composition Wholesale Brick Suppliers

Evaluate properties of fly ash based Geopolymer Bricks

Clay bricks are more porous Fly ash bricks are less porous The cost of clay brick is higher than fly ash The cost of fly ash brick is approximate 30%lower brick. Clay brick are uneven in shape as the mostly Uniform in shape and smooth in finish as the clay bricks are made manually.